Metal-ceramic built-up unit, a built-up framework for transfer of oxide ions, a built-up unit having a capability of sealing

A technology of oxides and structures, applied in the direction of single-tube conductors, separation methods, semi-permeable membrane separations, etc., can solve the problems of molten glass not being able to withstand pressure differences, laborious sealing, and inability to obtain stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

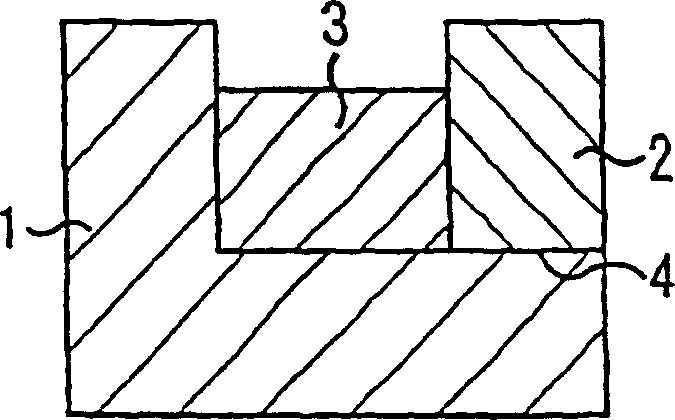

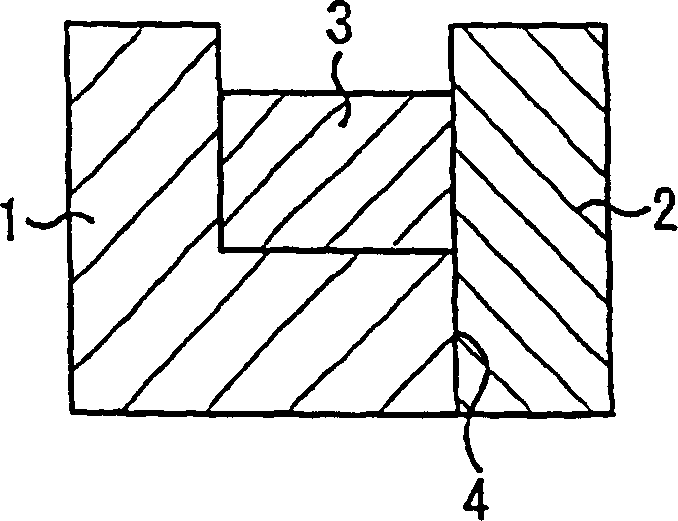

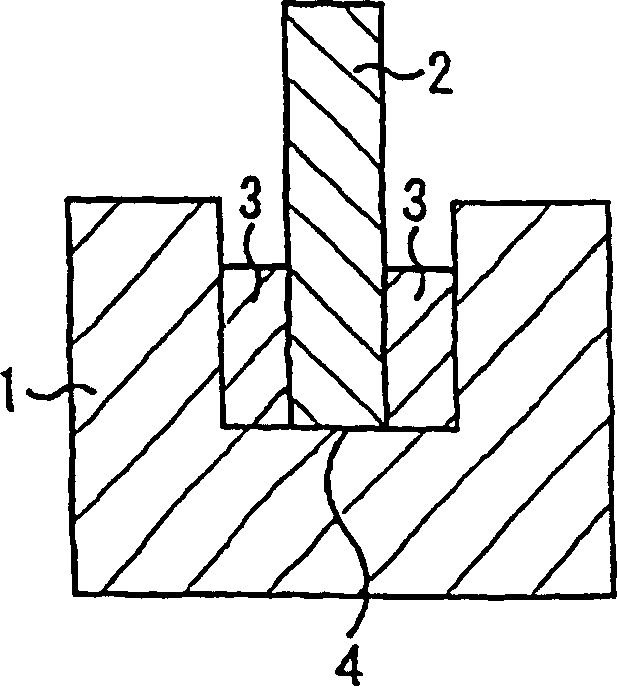

[0153] In fact, the following is added with Figure 5 Exemplary oxygen separation device.

[0154] That is, the hollow member 21 has a structure in which a dense membrane of oxide ion-permeable ceramics is formed on a cylindrical porous ceramic substrate with one end closed. For the oxide, both the dense membrane and the porous substrate are SrCo 0.9 Nb 0.1 o x . SUS304 steel was used for the flange member 22 and the core member 25, and SUS310S steel was used for the integrated plate 26 and the oxygen separation container 29. A dense film was formed with a thickness of about 50 μm on the porous substrate by using a slurry coating method. Silver clay is inserted into the storage portion formed by combining a plurality of members, and heat-treated at the softening temperature of silver to form 23, 27, and 30 made of silver.

[0155] As a result of experiments conducted at 850° C. while maintaining the pressure of the compressed air in the region 32 at 1 MPa, it was confirme...

Embodiment 2

[0159] In order to maximize the capabilities of the device of the present invention, a material search for an optimum composite was carried out. First, prepare an oxide by the method shown below.

[0160] As the raw material of the sample, La 2 o 3 , CaCO 3 , SrCO 3 、BaCO 3 , Fe 2 o 3 、Co 3 o 4 , Nb 2 o 5 、 Ta 2 o 5 、In 2 o 3 , SnO 2 , V 2 o 5 、TiO 2 、Cr 2 o 3 , MnO 2 , CuO, ZnO, NiO, Li 2 CO 3 , MgO, respectively weigh the required amount, use ethanol as a dispersant, and carry out ball milling and mixing with zirconia balls for 2 hours. The resulting slurry was dried, disintegrated, placed in a horn sheath made of MgO, and fired at 900° C. for 12 hours in the air. The calcined powder obtained by crushing is packed in a φ12mm die, uniaxially molded, and then put into an ice bag for CIP molding. In a horn sheath made of MgO, the obtained molded body was fired at an optimum temperature in the temperature range of 1150-1300° C. for 5 hours to obtain a di...

Embodiment 3

[0197] The ceramic-metal composite structure obtained by the same treatment as in Example 1 was heat-treated again, and the room temperature-high temperature (850° C.) cycle resistance was evaluated. This was repeated up to 10 times, and the airtightness at high temperature was checked in the same manner as in Example 2 for the last 10th time. As a result, it was confirmed that the airtightness was good. Then, when it cooled to room temperature, and evaluated similarly to Example 1, both adhesiveness and peelability were favorable. Due to such circumstances, the ceramic-metal composite structure of the present invention proved to be excellent in cycle resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com