Hard template synthetic composite hole zeolite molecular sieve and its preparing method

A zeolite molecular sieve and composite pore technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of large specific surface area, high preparation cost, and low acidity, and achieve high catalytic activity, simple method, and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

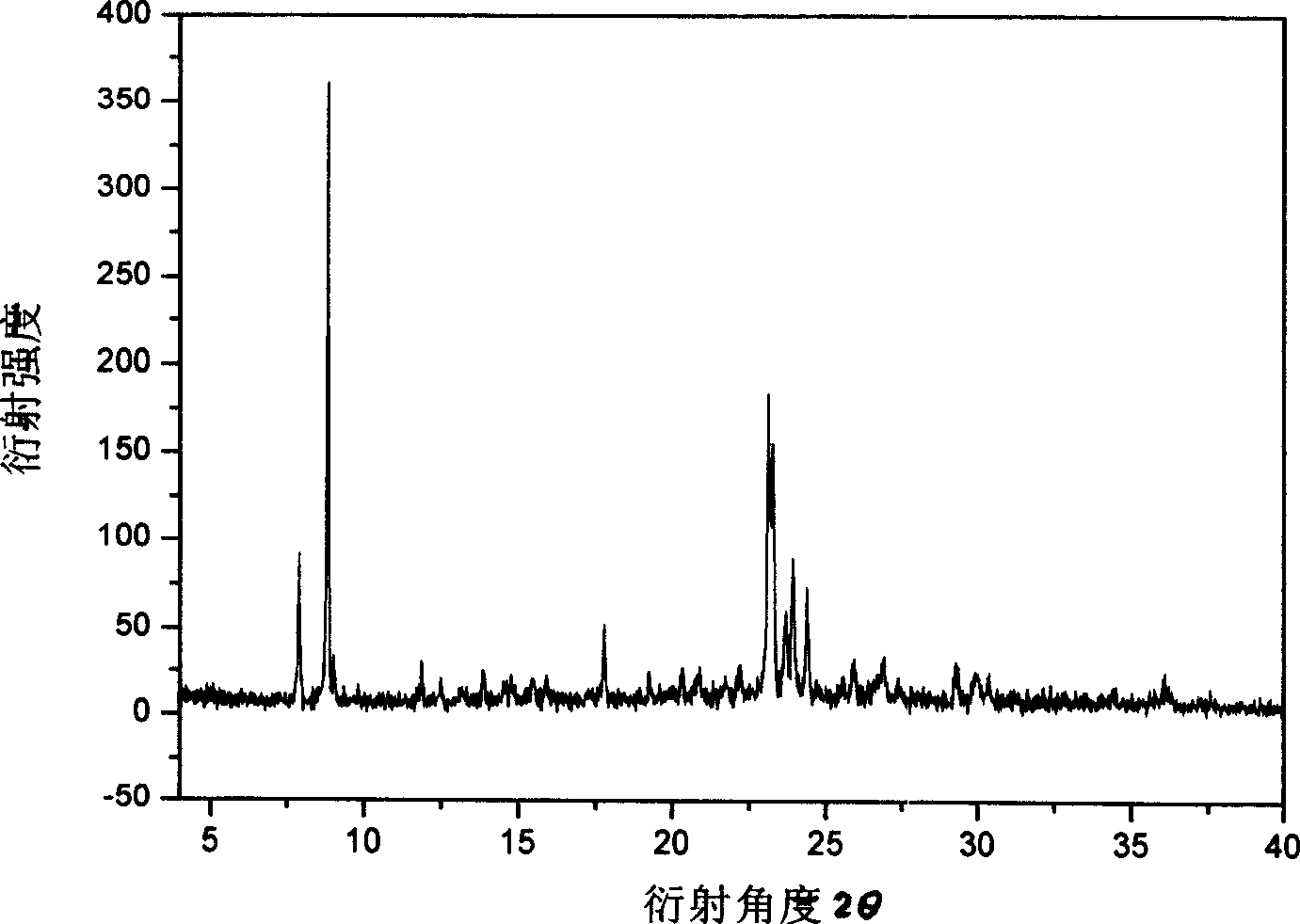

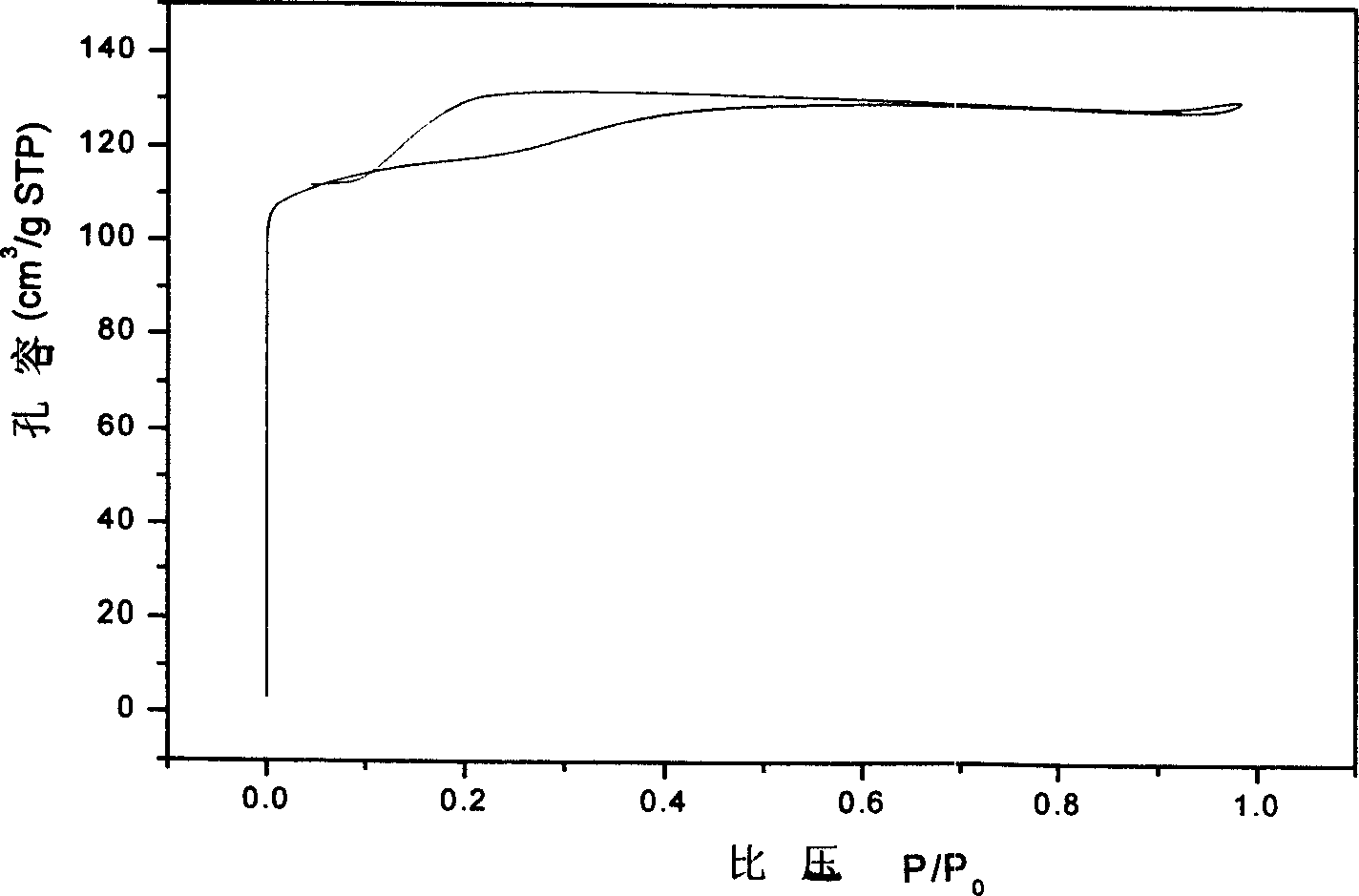

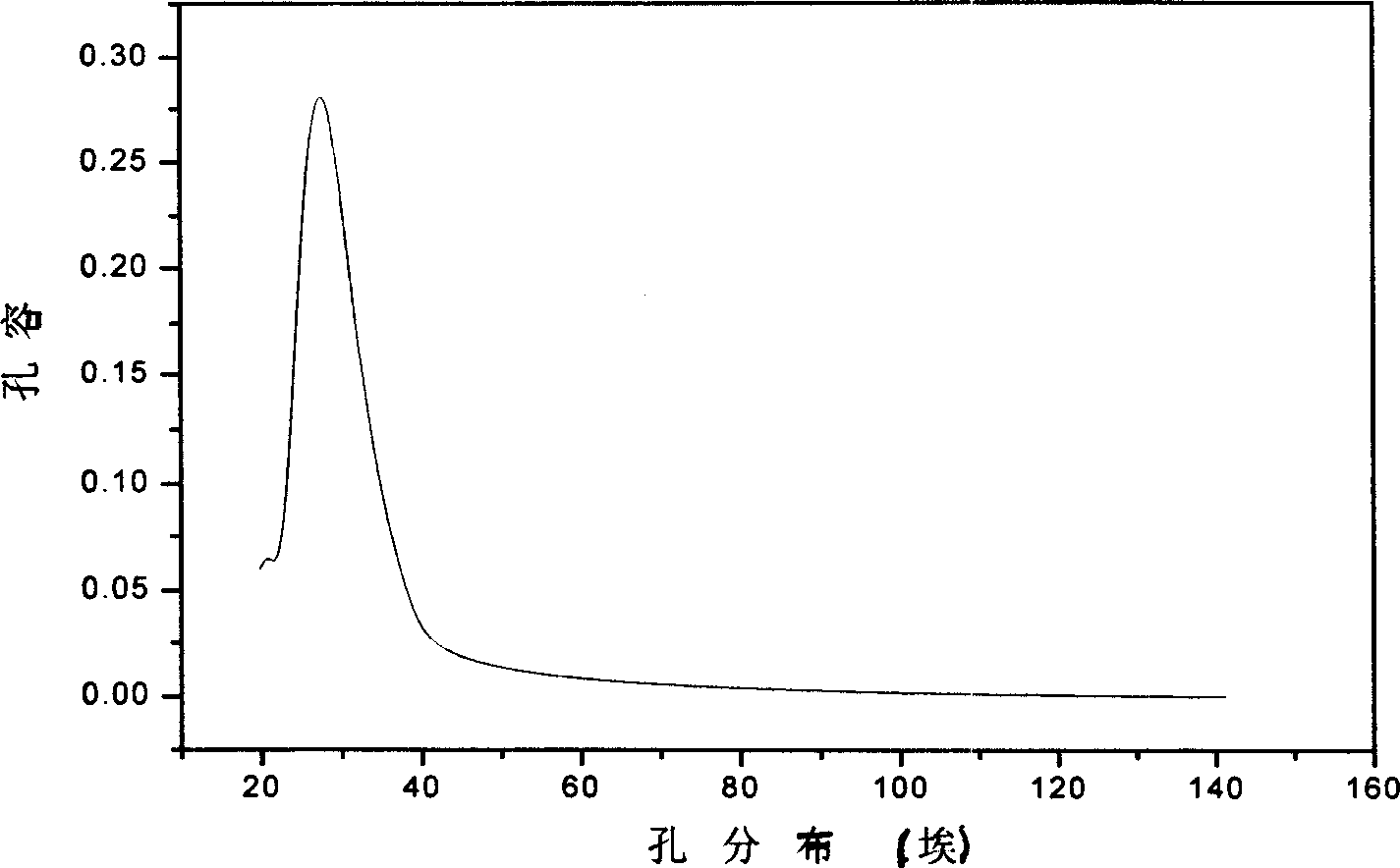

[0020] Example 1: Using rice husk and TPABr as a template, and using silicon oxide in rice husk as a silicon source to synthesize a Silicalite-I zeolite molecular sieve with a composite pore structure

[0021] Synthetic raw materials: dry rice husk as silicon source, rice husk and TPABr as template, NH 4 F as a mineralizer. After determination, SiO in the rice husk used in this embodiment 2 The mass percentage accounted for is 20%, for example, if 20 grams of SiO 2 , you will add 100 grams of rice husk.

[0022] Synthetic ratio: SiO 2 / 40H 2 O / (0.1~0.35)TPABr / NH 4 F.

[0023] Synthetic steps: First, the NH 4 Dissolve F and TPABr in an appropriate amount of water, then stir evenly, add rice husk, stir vigorously for 10 hours, and crystallize the obtained mother liquor.

[0024] Crystallization conditions: the reactant is crystallized at 140-180°C for 20-192 hours, and the obtained product is filtered, washed, and dried at room temperature. Finally, the sample is first ...

Embodiment 2

[0028] Example 2: Using rice husk and TPABr as a template, and using silicon oxide in rice husk as a silicon source to synthesize a ZSM-5 zeolite molecular sieve with a composite pore structure

[0029] Synthetic raw materials: washed and dried rice husk as silicon source, TPABr as template, NH 4 F as a mineralizer, Al 2 (SO 4 ) 3 as a source of aluminum.

[0030] Synthetic ratio: SiO 2 / (0.002-0.04)Al 2 o 3 / 40H 2 O / (0.1~0.35)TPABr / NH 4 F.

[0031] Synthetic steps: First, the NH 4 F. Al 2 (SO 4 ) 3 Dissolve TPABr and TPABr in appropriate amount of water, then stir evenly, add rice husk, stir vigorously for 12 hours, and put the obtained mother liquor into a reactor for crystallization.

[0032] The crystallization conditions and calcination conditions are the same as in Example 1, and ZSM-5 zeolite molecular sieves are prepared.

[0033] Preparation of HZSM-5 catalyst: First, the original powder of ZSM-5 molecular sieve that has removed the template agent was mi...

Embodiment 3

[0034] Example 3: Using rice husk and TPAOH as a template, using silicon oxide and tetraethyl orthosilicate in rice husk as a silicon source to synthesize a ZSM-5 zeolite molecular sieve with a composite pore structure

[0035] Synthetic raw materials: washed and dried rice husk, TPAOH, sodium metaaluminate, tetraethyl orthosilicate (in this embodiment, silicon oxide in rice husk is used as silicon source).

[0036] Synthetic ratio: (0.01~0.1) Al 2 o 3 / SiO 2 / (0.01~0.1)Na 2 O / (0.04~1.8)TPAOH / (10~60)H 2 O. SiO here 2 The ratio is the ratio of ethyl orthosilicate and silicon oxide in rice husk as a silicon source; SiO provided by orthosilicate 2 It accounts for 0-80% of the total silicon source.

[0037] Synthesis steps: first dissolve TPAOH and sodium metaaluminate in an appropriate amount of water, stir evenly, add tetraethyl orthosilicate, stir well, then age at 80-110°C for 1-6 hours, add rice husk to the obtained solution, Continue to stir until uniform, and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com