Prepn process of microcapsule containing Hansa yellow 100 electrophoresis liquid

A Hansa yellow and electrophoretic fluid technology, applied in the field of microcapsule preparation containing Hansa yellow 10G electrophoretic fluid, can solve the problems of scratch resistance, poor pressure performance, poor capsule wall strength, high mechanical strength, etc., and achieve high transparency , good geometric shape, excellent flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

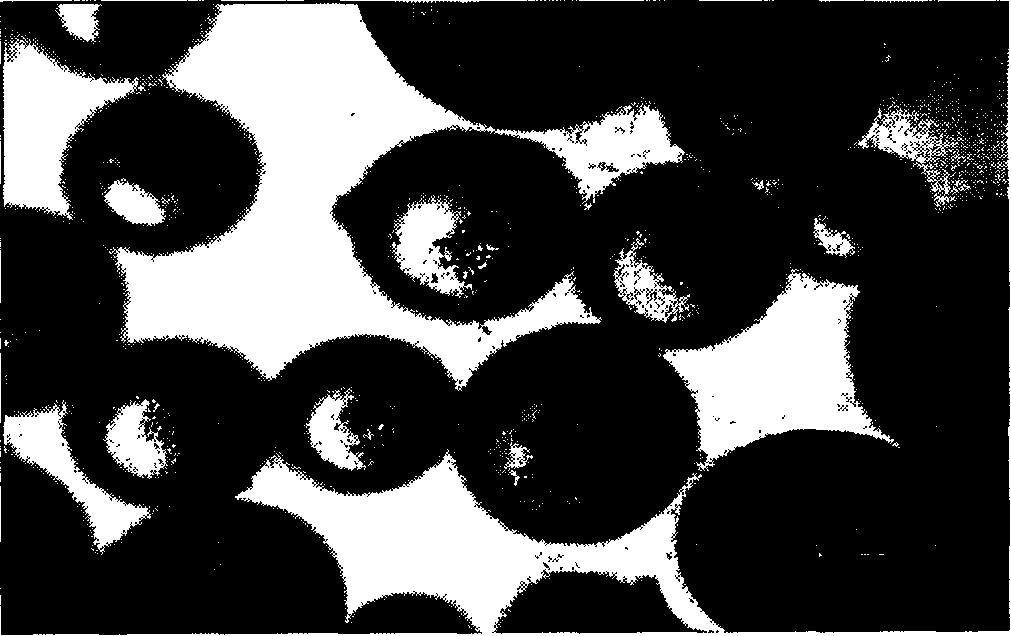

Image

Examples

example 1

[0015] Take 100g of toluene, add 0.5g of Hansa yellow 10G to it, add 0.1g of Span 80, add 100g of glass beads, grind at 150rpm for 1h, and then filter to remove the glass beads to obtain a stable and dispersed yellow electrophoretic suspension.

[0016] Mix 0.5g of yellow electrophoretic suspension and 0.005g of bisphenol A type epoxy resin E44 to form a uniform dispersion, take 1g of gelatin and 0.5g of gum arabic at 40°C to make aqueous solutions with a mass concentration of 1% respectively, and disperse the above Add the gelatin solution into the gum arabic solution to disperse for 1min, stir to obtain an o / w emulsion, add the prepared gelatin solution into the emulsion under stirring, and adjust the pH value of the system to 10% acetic acid solution at 40°C 4. Slowly lower the temperature to 0°C, add 2g of 5% glutaraldehyde aqueous solution dropwise to the above system to cross-link the microcapsule wall, continue the reaction for 0.5h, add 5g of 1% carboxymethyl The sodiu...

example 2

[0018] Take 100g of cyclohexane, add 1g of Hansa yellow 10G to it, add 0.3g of OP-10, add 100g of glass beads, grind at 300rpm for 4h, and then filter to remove the glass beads to obtain a stable and dispersed yellow electrophoretic suspension.

[0019] Mix 20g of yellow electrophoretic suspension and 0.5g of bisphenol A epoxy resin E51 to form a uniform dispersion, take 1g of gelatin and 1g of gum arabic at 60°C to prepare aqueous solutions with a mass concentration of 5%, and add the above dispersion to Disperse in the gum arabic solution for 15 minutes, stir to obtain an o / w emulsion, add the prepared gelatin solution into the emulsion under stirring, and adjust the pH value of the system to 4.5 with a mass concentration of 1% hydrochloric acid solution at 60°C. Slowly lower the temperature to 10°C, add 10 g of 5% glutaraldehyde aqueous solution dropwise to the above system to cross-link the microcapsule wall, continue the reaction for 1 hour, and add 6 g of 5% sodium carbox...

example 3

[0021] Take 100g of tetrachlorethylene, add 2g of Hansa yellow 10G to it, add 0.5g of didecyldimethylammonium bromide, add 100g of glass beads, grind at 500rpm for 8h, and then filter to remove the glass beads to obtain stable dispersion Yellow electrophoretic suspension.

[0022] Mix 40g of yellow electrophoretic suspension and 1g of cycloaliphatic epoxy resin ERR0300 to form a uniform dispersion, take 1g of gelatin and 2g of gum arabic at 70°C to make aqueous solutions with a mass concentration of 10%, and add the above dispersion to Arabica Disperse in the gelatin solution for 30 minutes, stir to obtain an o / w emulsion, add the prepared gelatin solution into the emulsion under stirring, adjust the pH value of the system to 5 with a mass concentration of 1% sulfuric acid solution at 70°C, and lower the temperature Slowly lower to 15°C, add 20g of 5% formaldehyde aqueous solution dropwise to the above system to cross-link the microcapsule wall, continue the reaction for 2h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com