Highly oriented laminated dihydroxy composite metal oxide film and its preparing method

A technology of layered double hydroxyl and oxide films, applied in the direction of oxide/hydroxide preparation, chemical instruments and methods, single crystal growth, etc., can solve the problems of complex preparation methods, discontinuous LDHs, poor film orientation, etc. Achieve the effect of simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Polystyrene was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 3 days, rinsed with deionized water, and dried at 40°C for later use.

[0044] In a 1000mL reaction vessel, 1.923gMg(NO 3 ) 2 ·6H 2 O and 1.407gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water to prepare a solution with a total metal ion concentration of 0.015 mol / L. After adding 6.306g of urea and dissolving it, suspend the surface sulfonated polystyrene sheet horizontally in the solution, seal the container, and react at a constant temperature of 70°C for 9 days. After the solution was cooled, the polystyrene sheet was taken out, rinsed with deionized water, and dried at 40°C for 24 hours.

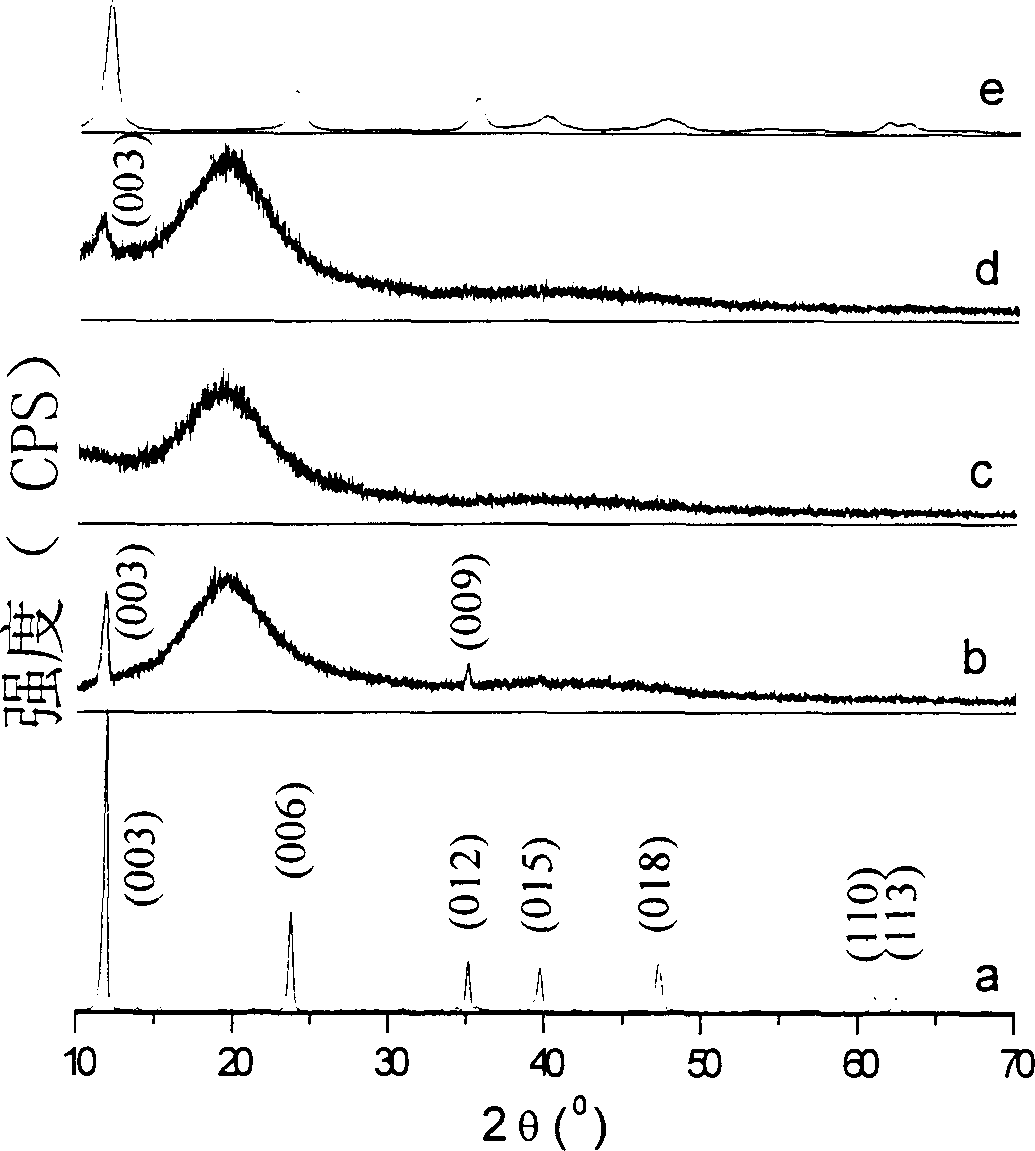

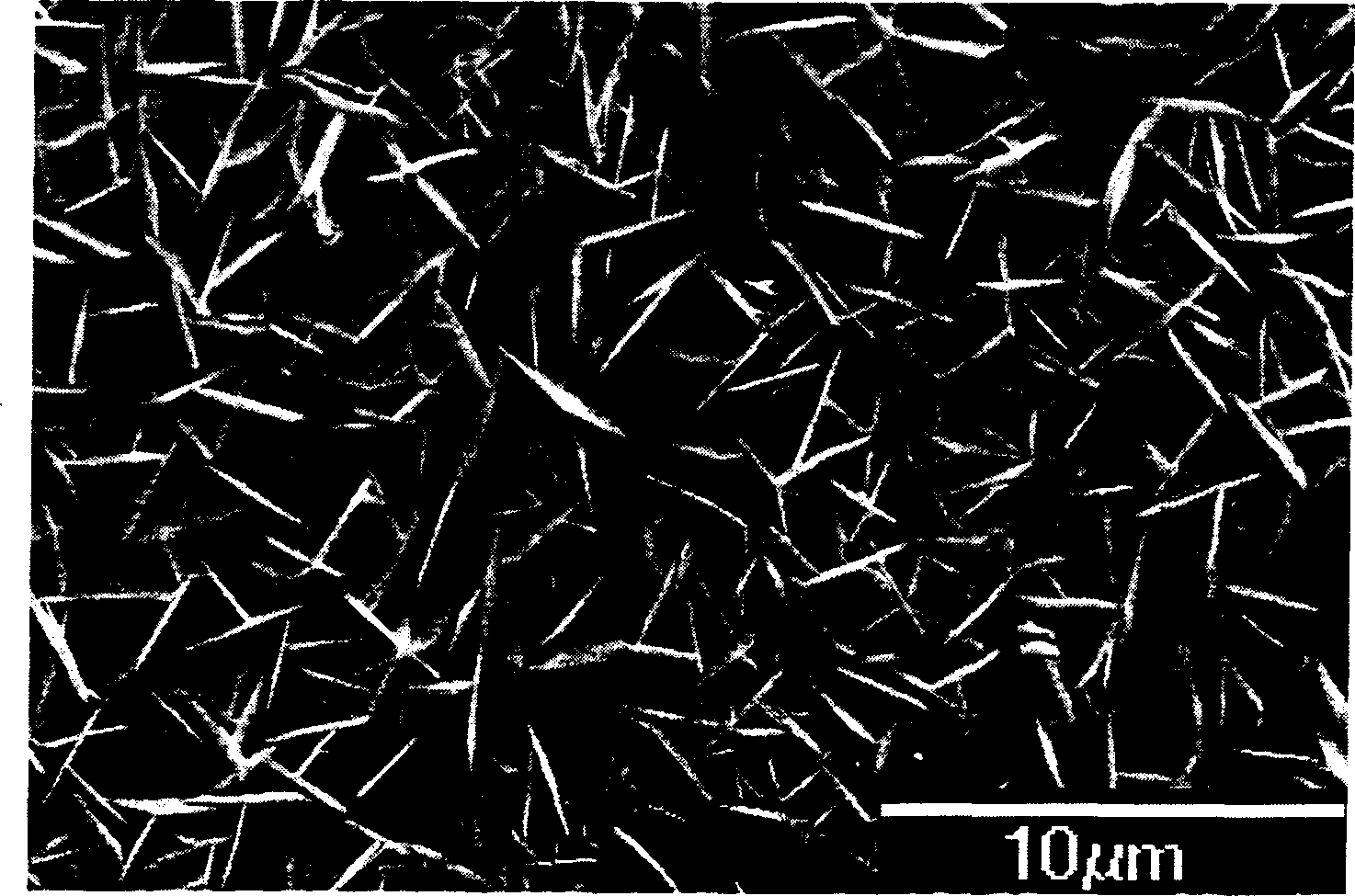

[0045] The film formed on the surface of polystyrene is magnesium aluminum carbonate LDHs film, the molar ratio of Mg / Al in the film is 1.61, and the content of Al on the film surface is 0.0143mol / m 2 . Its XRD spectrum is shown in figure 1 (b), FESEM phot...

Embodiment 2

[0047] Polystyrene was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 3 days, rinsed with deionized water, and dried at 40°C for later use.

[0048] In a 1000mL reaction vessel, 0.288gMg(NO 3 ) 2 ·6H 2 O and 0.141gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water at a molar ratio of 4:1 to prepare a solution with a total metal ion concentration of 0.002 mol / L. After adding 0.608g of urea and dissolving it, suspend the surface sulfonated polystyrene sheet horizontally in the solution, seal the container, and react at a constant temperature of 60°C for 12 days. After the solution was cooled, the polystyrene sheet was taken out, rinsed with deionized water, and dried at 40°C for 24 hours.

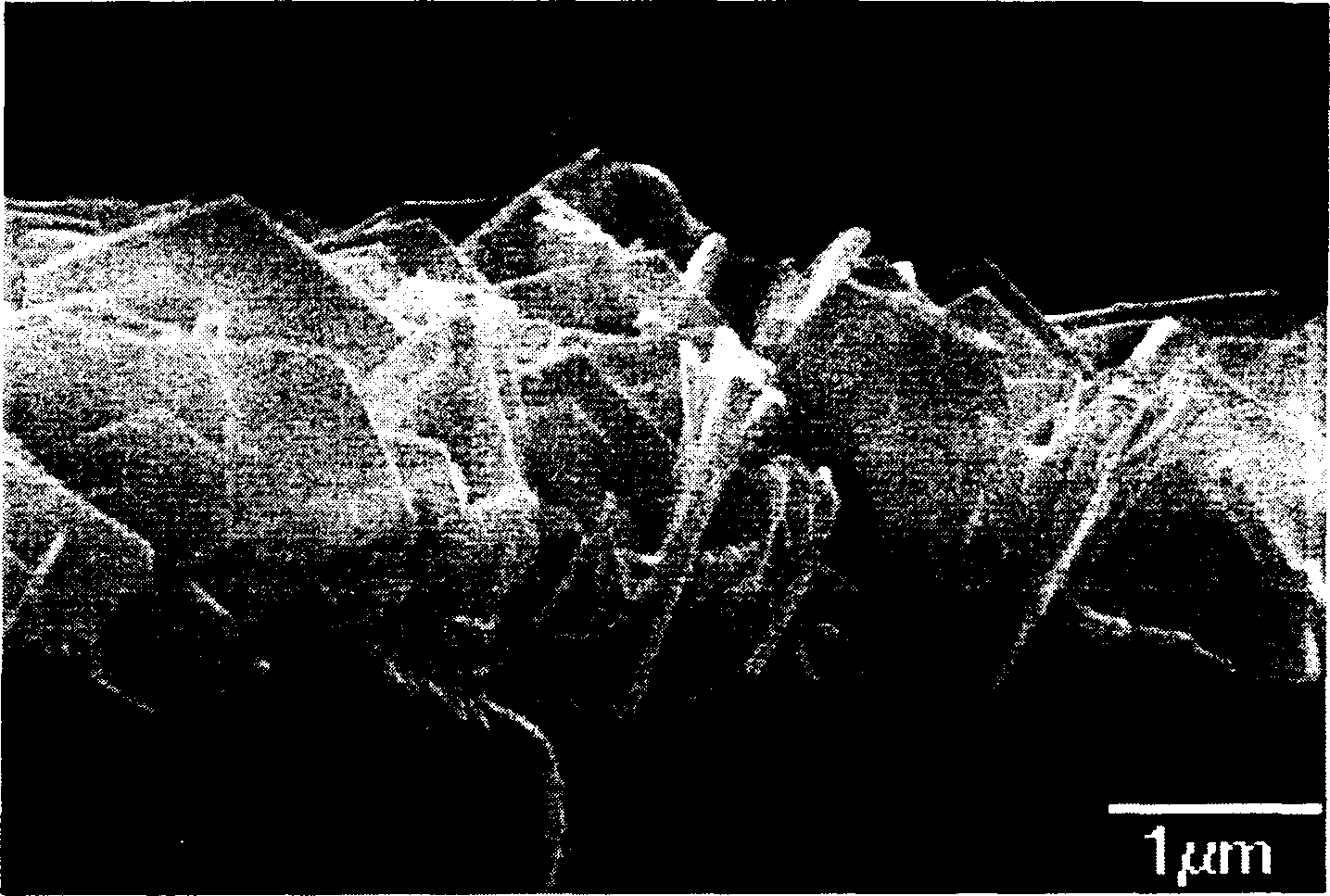

[0049] The film formed on the surface of polystyrene is the magnesium aluminum carbonate LDHs film obtained. The Mg / Al molar ratio in the film is 1.84, the film thickness is about 1.70 μm, and the Al content on the film surface is 0.0...

Embodiment 3

[0051] Styrene-divinylbenzene copolymer was hot-pressed into sheets, soaked in commercially available concentrated sulfuric acid for 5 days, rinsed with deionized water, and dried at 30°C for use.

[0052] In a 1000mL reaction vessel, 1.923gMg(NO 3 ) 2 ·6H 2 O and 1.407gAl(NO 3 ) 3 9H 2 O was dissolved in 750 mL of deionized water to prepare a solution with a total metal ion concentration of 0.015 mol / L. After adding 6.306g of urea and dissolving it, suspend the surface sulfonated styrene-divinylbenzene copolymer substrate horizontally in the solution, seal the container, and react at a constant temperature of 90°C for 3 days. After the solution was cooled, the styrene-divinylbenzene copolymer sheet was taken out, rinsed with deionized water, and dried at 50°C for 24 hours.

[0053] The film formed on the surface of styrene-divinylbenzene copolymer is the obtained magnesium aluminum carbonate LDHs film. The Mg / Al molar ratio in the film is 1.66, and the Al content on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com