Super strong acid resistant rubber material and its preparation method

A rubber material and strong acid resistance technology, applied in the field of special rubber and its preparation, can solve problems such as poor tolerance, and achieve the effects of improving cross-linking density, strength and cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a. Weigh 70kg of chlorosulfonated polyethylene rubber (CSM-40); chlorinated polyethylene rubber CM-352L) 30kg; fluorine rubber (fKM-2463) 10kg; polytetrafluoroethylene 4kg; zinc methacrylate 10kg; Magnesium base acrylate 5kg; N220 carbon black 20kg; quartz powder 20kg; barium sulfate 5kg; superfine talc powder 5kg; rosin 10kg; stearic acid 0.5kg; TP-95 oligomer 5kg; TRA curing agent 2.5kg; DM accelerator 0.5kg; lead monoxide 10kg.

[0034] b. Place the chlorosulfonated polyethylene rubber, chlorinated polyethylene rubber, and fluoro rubber in an internal mixer and masticate at 165°C for 10 minutes; add polytetrafluoroethylene and rosin to masticate at 160°C for 4 minutes; add a Zinc base acrylate, magnesium methacrylate, stearic acid, carbon black, ultrafine talc, quartz powder, barium sulfate, oligomer, plasticize at 160℃ for 6min, shut down, turn over and discharge, cool to below 65℃ use.

[0035] c. Add accelerator DM, vulcanizing agent TRA, and vulcanization activator l...

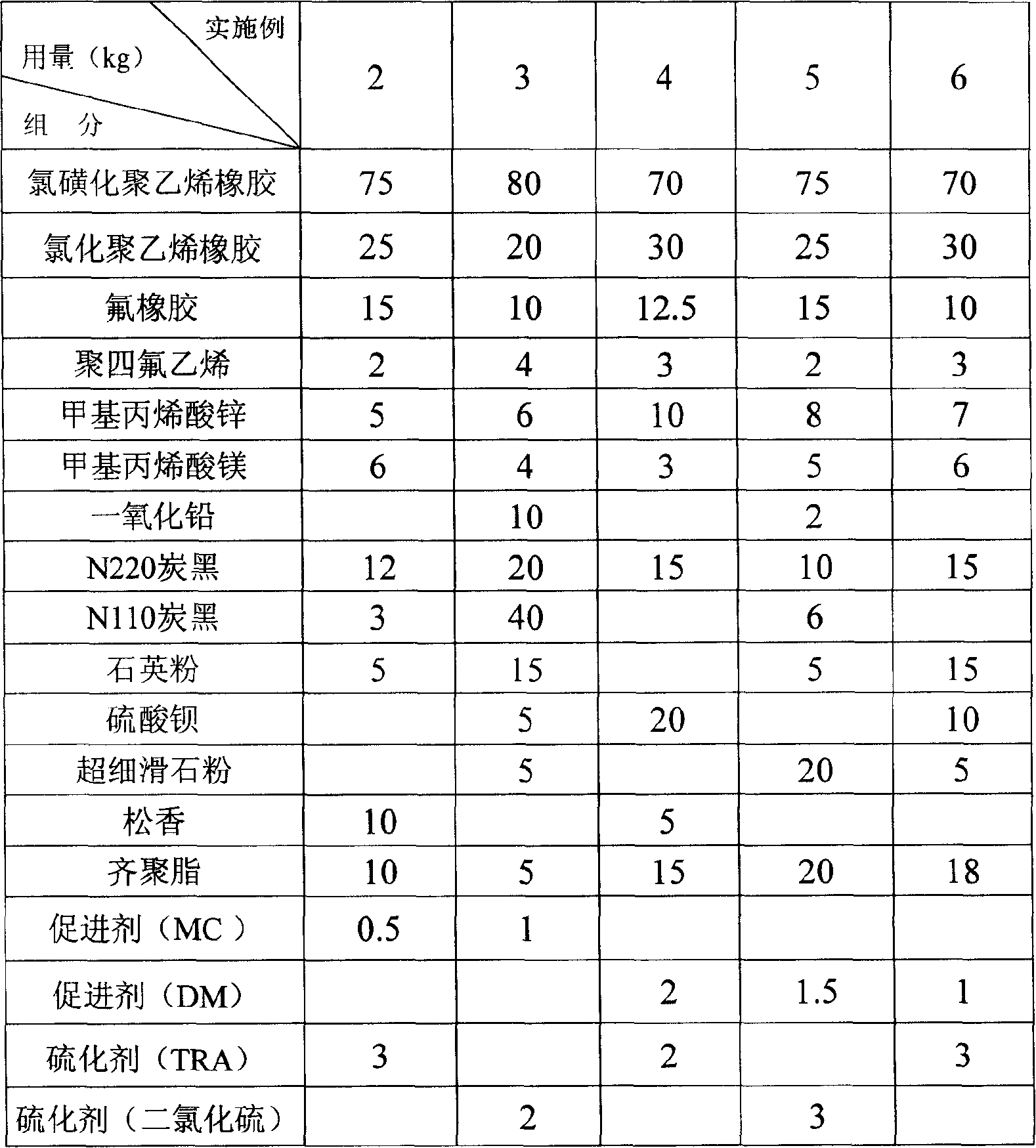

Embodiment 2~6

[0037] Examples 2-6 are shown in the following table:

[0038]

[0039] The preparation method of Examples 2-6 is the same as that of Example 1, except that the process parameters and the amount of raw material components are different, but they all have the effects of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com