Thermo philic alkali beta glucosidase and its coding gene

A glucosidase, alkaline technology, applied in genetic engineering, plant genetic improvement, enzymes, etc., can solve the problem of β-glucosidase not seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

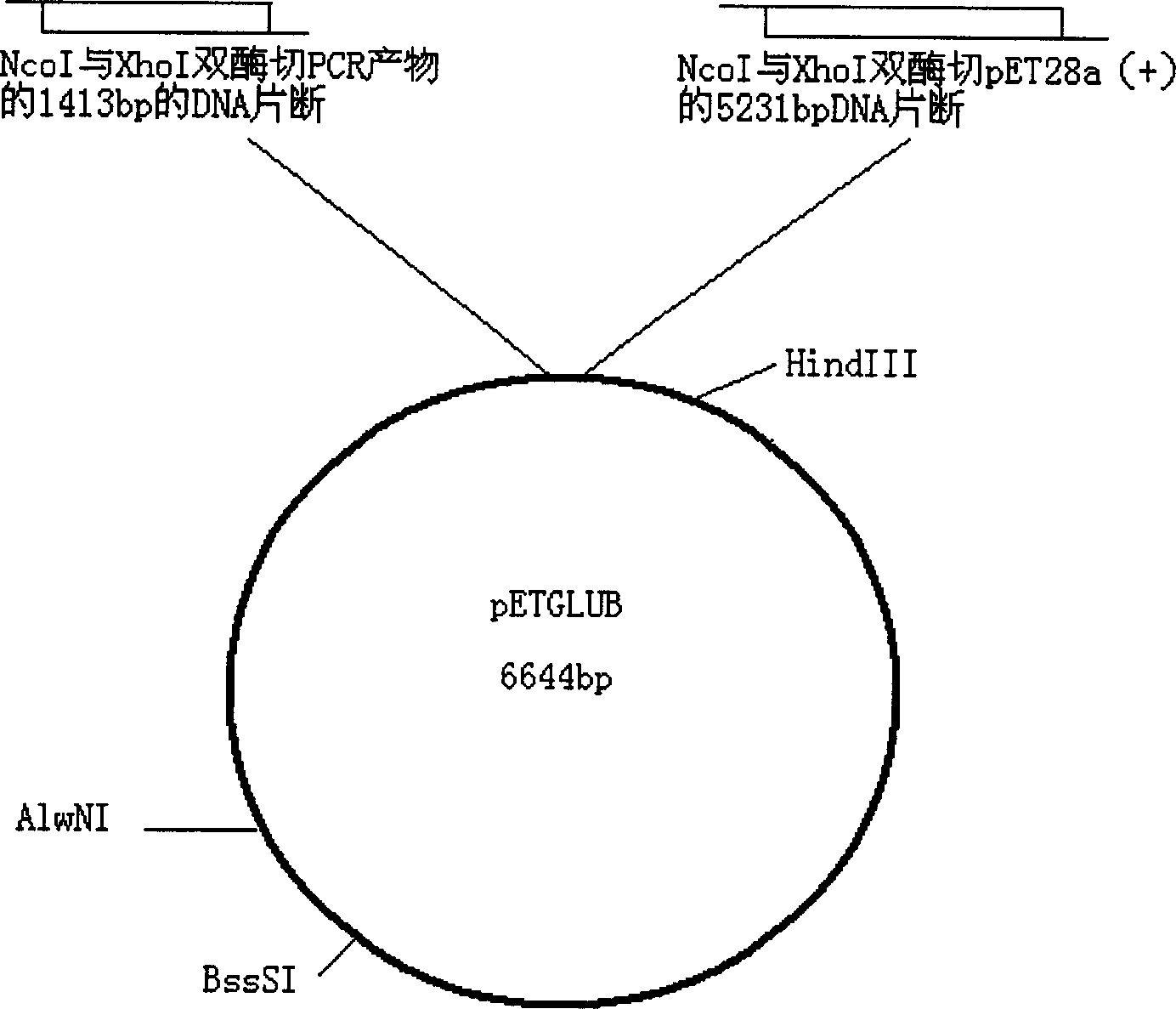

Method used

Image

Examples

Embodiment 1

[0036] 1. Extraction of total DNA from Bacillus thermodenitrophilus NG80-2 (CGMCC No.1228)

[0037] Studies have shown that the gene encoding β-glucosidase can be isolated from the genome of Geobacillus thermodenitrificans NG80-2, which is especially suitable for degrading cellobiose under high temperature conditions. It maintains the high activity of the enzyme in a high temperature environment, which is different from the characteristics of the known β-glucosidase, and is a new type of β-glucosidase. Therefore, in this example, the thermophilic denitrification bacillus NG80-2 obtained from the oil well formation water separation of Guan 69-8 Block, Dagang Oilfield, Tianjin, China was used, and 3 ml of the fresh culture cultured overnight was used to collect the bacteria by centrifugation. , the cells were suspended in 250 microliters of 50mM Tris buffer (pH8.0), added 10 microliters of 0.4M EDTA (pH8.0), mixed well and incubated at 37°C for 20min, then added 30 microliters o...

Embodiment 2

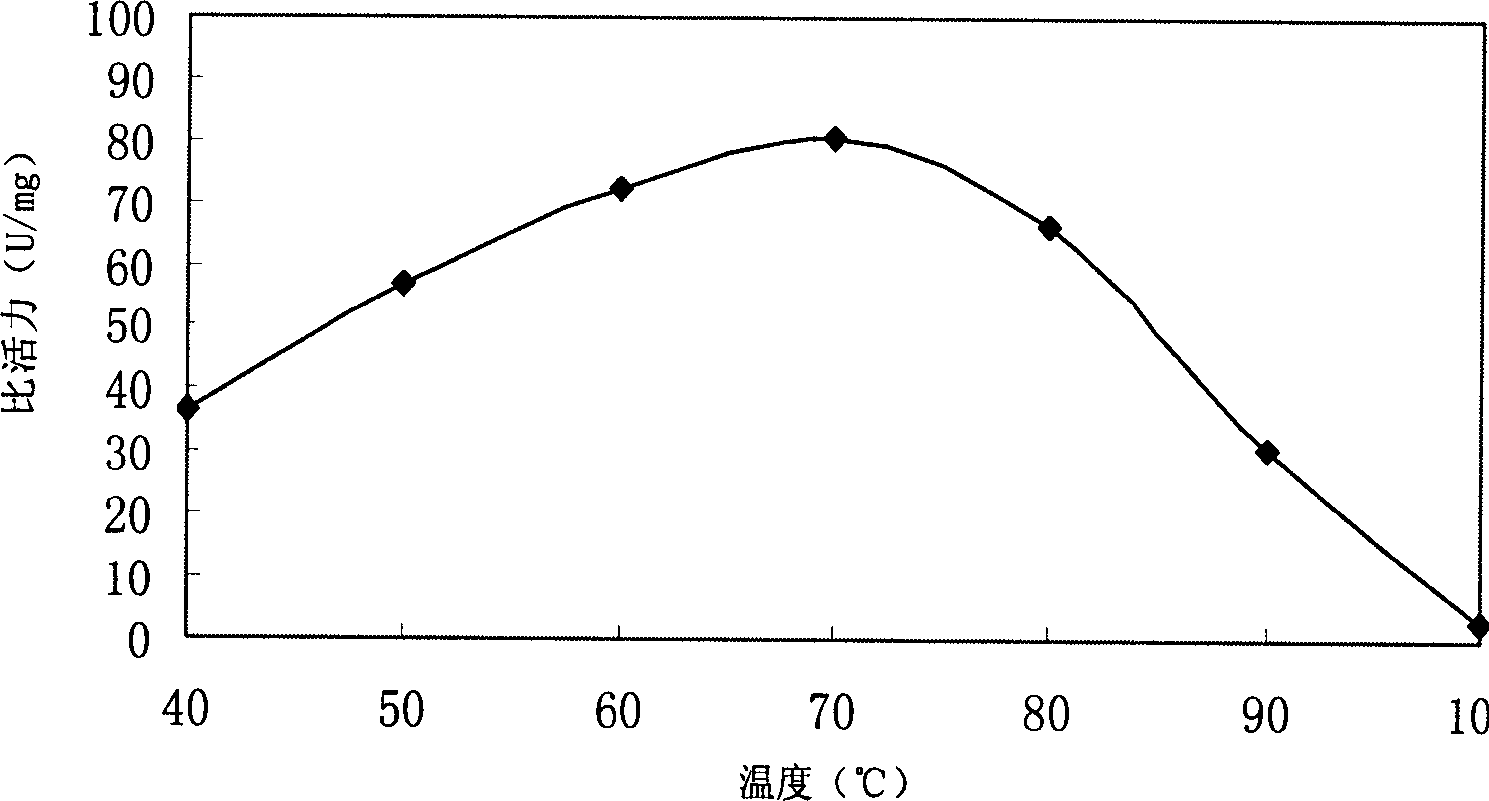

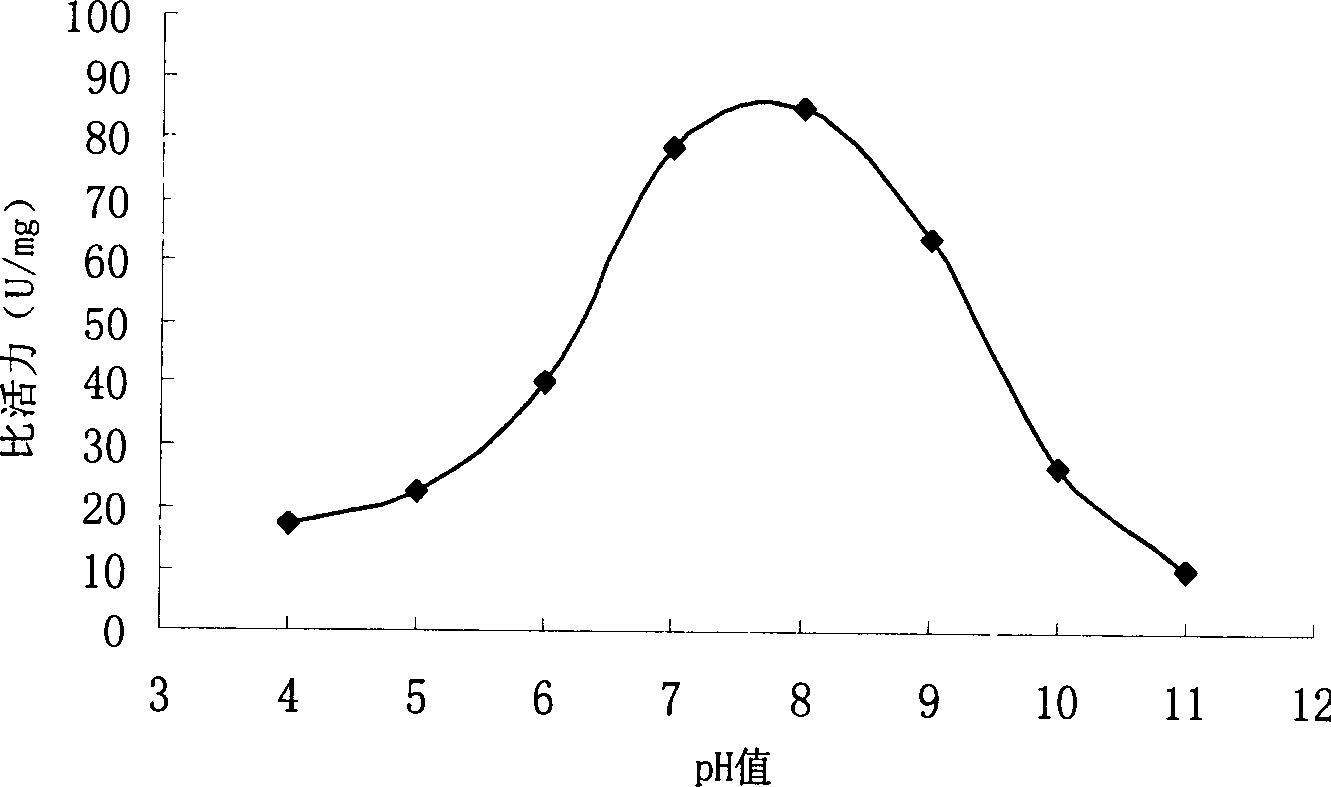

[0048] Embodiment two Purification and properties of recombinant β-glucosidase of the present invention

[0049] Insert the above-mentioned recombinant strain E. Coli BL21GLUB monoclonal into 20ml of LB medium containing 50μg / ml Kan, culture at 37°C, 180rpm / min for 12 hours, and then insert the culture at 1% (V / V) inoculum 200ml of LB medium containing 50μg / ml Kan (total 10 shake flasks), 37°C, 220rpm / min culture A600 is 0.6, add IPTG to a final concentration of 0.2mM, 37°C, 150rpm / min induction for 4 hours. The cells were collected by centrifugation, suspended in 50 mM Tris-Cl (pH 7.5) buffer, and the cells were disrupted by ultrasonic waves. The centrifuged supernatant was the crude extract of recombinant β-glucosidase. The supernatant was purified by chelating Sepharose nickel affinity column chromatography, and the obtained enzyme preparation showed a band on SDS-PAGE. The basic properties of this recombinant β-glucosidase were determined using standard methods known ...

Embodiment 3

[0050] Embodiment three Recombinant β-glucosidase of the present invention hydrolyzes cellobiose

[0051] In the 2% cellobiose solution (prepared with pH7.5, 0.2M sodium phosphate buffer), add the purified enzyme solution prepared in the above-mentioned embodiment 2, and the addition amount is 2% of the volume of the cellobiose solution. One-tenth, heat up to 70°C for six hours. The above-mentioned recombinant thermophilic alkaline β-glucosidase hydrolyzes cellobiose to produce glucose as measured by high pressure liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com