Carbon oil in use for making carbon resistance element, preparation method, and prepared element of carbon resistance

A carbon oil and component technology, applied in the manufacturing of electrical components, resistors, resistors, etc., can solve the problems of cumbersome process, cumbersome preparation process, destroying the performance of carbon resistance components and product resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

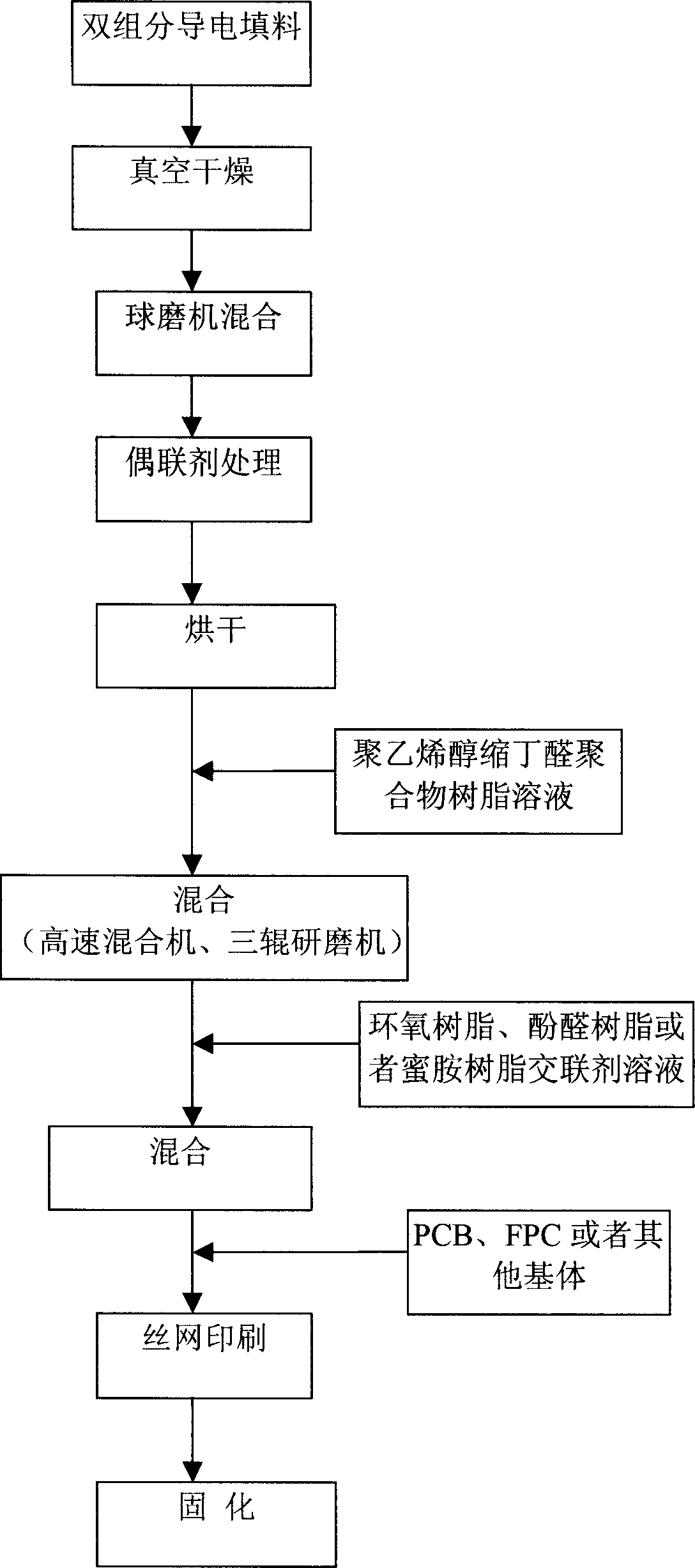

[0047] according to figure 1 As shown in the process flow chart of preparing carbon resistance element, weigh the conductive carbon black (V-XC605, the average particle size is 35nm, the DBP value is 148cc / 100g, the BET surface area is 90m 2 / g) and nickel powder (INCO110, spherical particles, average particle size 0.8-1.5μm, BET surface area 0.9-2.0m 2 / g, volume resistivity 1.18μΩ·cm) 50 parts by weight of two conductive fillers (the weight ratio of the two is 3:1), dried in vacuum, mixed by a ball mill, and added 4% of the carbon black weight compound type A toluene solution of monoalkoxy titanate coupling agent (CT-136) (the concentration of the solution is 10 wt%) was mixed on a high-speed mixer for 2 hours, and then the solvent was evaporated. The resulting mixture was added to 100 parts by weight of polyvinyl butyral (Butvar B-76) and 500 parts by weight of methyl ethyl ketone and mixed uniformly, and then 100 parts by weight of phenolic resin (Santolink EP560) methyl ...

Embodiment 2

[0050] Weigh Conductex SC Ultra carbon black (average particle size is 20nm, DBP value is 115cc / 100g, BET surface area is 205m 2 / g) and nickel powder (INCO210, chain bead powder, average particle size 0.5-1.0μm, BET surface area 0.9-2.0m 2 / g, volume resistivity 1.18μΩ·cm) 100 parts by weight of the two conductive fillers (the weight ratio between the two is 4:1), dried in vacuum, mixed by a ball mill, and added 4% by weight of silane coupling agent ( DOWCORNING Z-6032) Mix on a high-speed mixer at 80°C for 2 hours. The resulting mixture was added to a solution consisting of 100 parts by weight of polyester polyurethane (product of Luoyang Liming Chemical Research Institute) and 800 parts by weight of ethanol and mixed uniformly, and then 100 parts by weight of a mass percentage concentration of 5 % Epoxy resin (Araldite TM 6069) After mixing the solution uniformly, the carbon oil product of the present invention is prepared.

[0051] Using the above carbon oil, manually screen...

Embodiment 3

[0053] Weigh Conductex SC Ultra carbon black (average particle size is 20nm, DBP value is 115cc / 100g, BET surface area is 205m 2 / g) and silver powder (ECP-Ag-F1, flakes, average particle size of 2-4μm, volume resistivity 1.6μΩ·cm) two conductive fillers 80 parts by weight (the weight ratio of the two is 5:1) , Vacuum drying, after mixing through a ball mill, add 5 wt% silane coupling agent (DOWCORNING Z-6106), mixed on a high-speed mixer at 60°C for 2 hours. The resulting mixture was added to 100 parts by weight of polyvinyl butyral (Butvar B-76) and 600 parts by weight of ethyl acetate and mixed uniformly, and then 100 parts by weight of 5% by mass melamine resin (Resimene 717) After mixing the solution uniformly, the carbon oil product of the present invention is prepared.

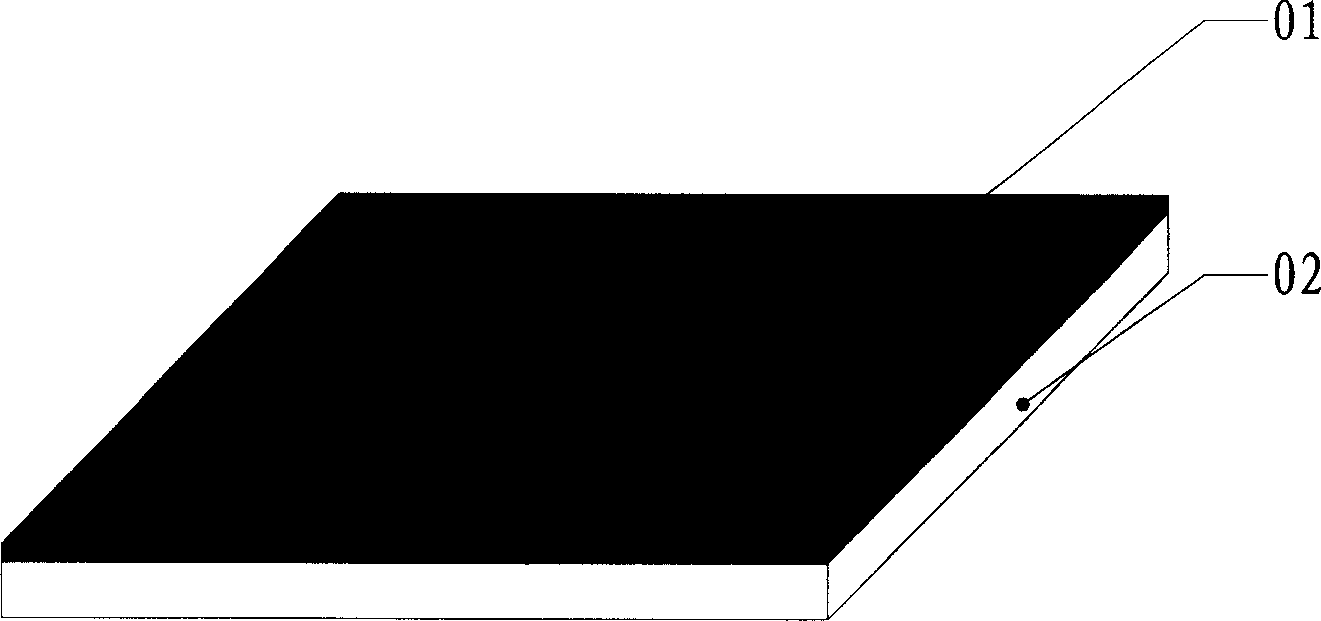

[0054] Using the above carbon oil, manually screen printing on the rigid circuit board, such as figure 2 The resistance of the carbon resistance element shown was tested after curing at 150°C for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com