Highly effective two-color white light high polymer material and method for making same

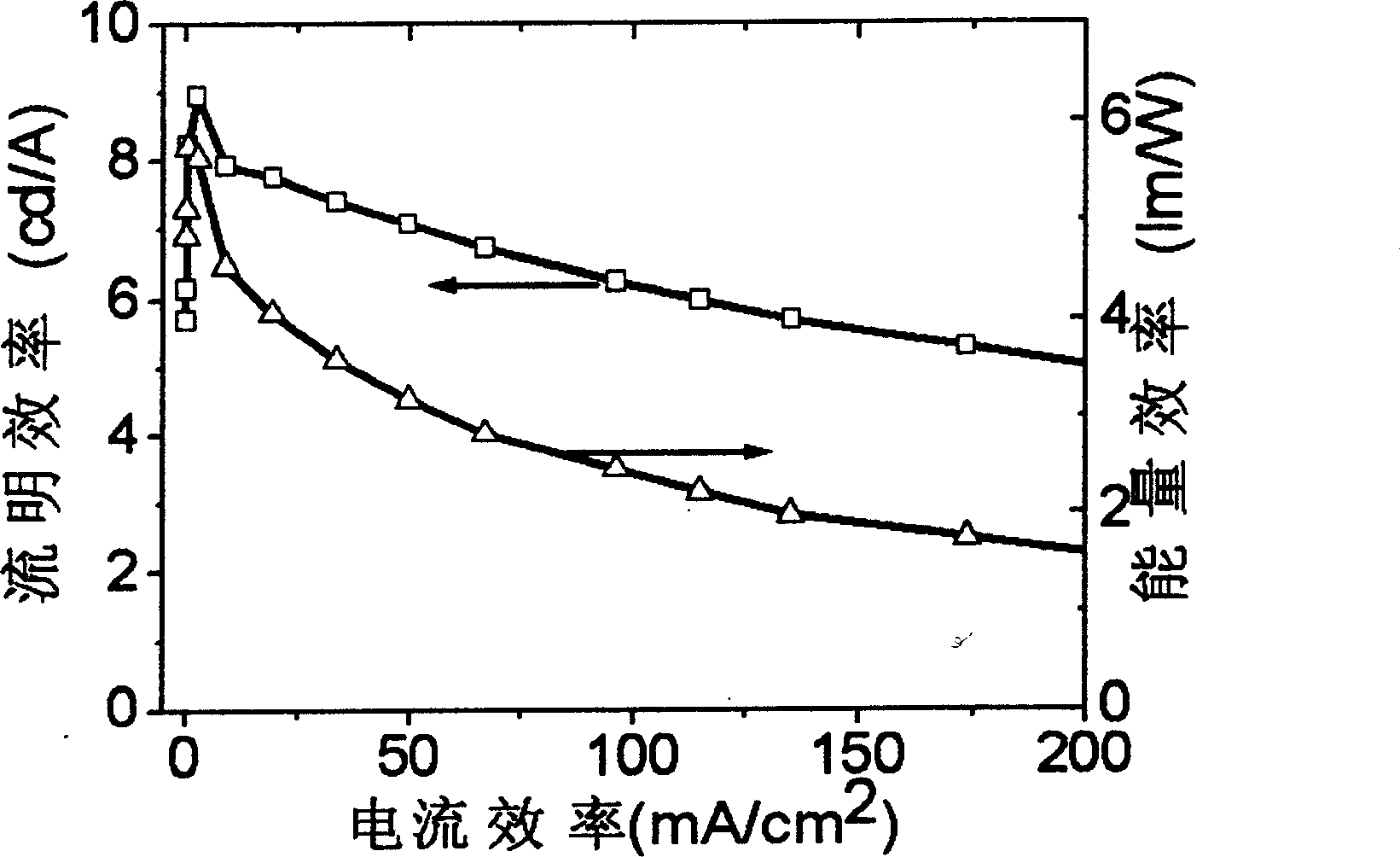

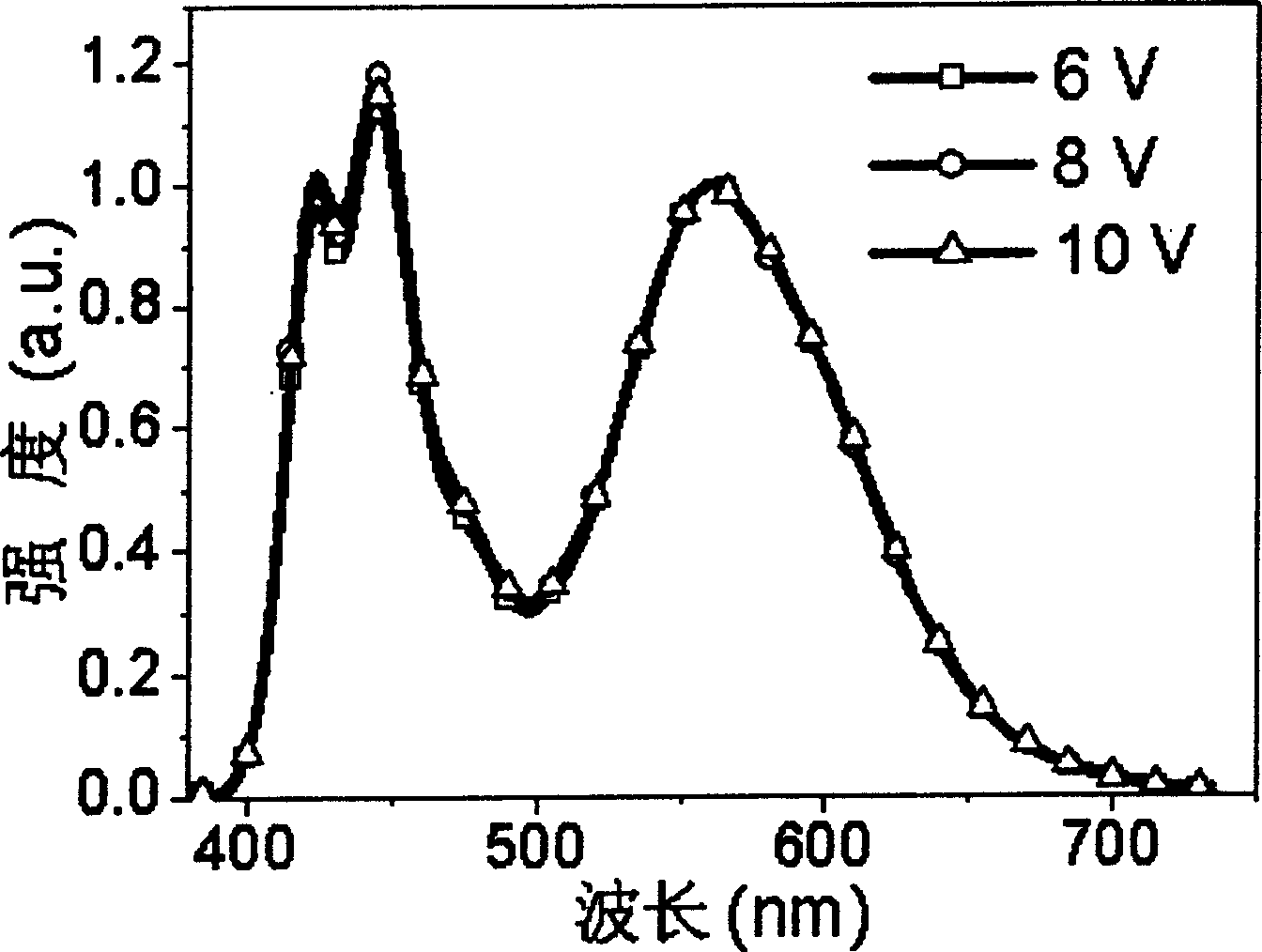

A polymer material and two-color technology, applied in the direction of luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems that the efficiency is still far from practicality, and achieve high electroluminescence efficiency, electroluminescence The effect of stable spectrum and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of 4,7-bis(4-(N-phenyl-N-(4-methylphenyl)amino)phenyl)-2,1,3-benzothiadiazole

[0024] Under the protection of nitrogen atmosphere, 4,7-dibromo-2,1,3-benzothiadiazole (1.47g, 5.0mmol), tributyl (4-(N-phenyl-N-(4- Methylphenyl) amino)-phenyl) tin (6.03g, 11mmol), tetrakis (triphenylphosphine) palladium (0.057g, 0.05mmol), the mixture of toluene (100ml) was reacted at 100°C for 30 hours , and then the reaction mixture was poured into potassium fluoride aqueous solution, extracted with chloroform, then washed three times with water, dried, concentrated, and column separated to obtain pure intermediate product 4,7-bis(4-(N-phenyl-N-(4- Methylphenyl)amino)-phenyl-)-2,1,3-benzothiadiazole 2.340 g, yield 72%.

Embodiment 2

[0025] Example 2: 4,7-bis(4-(N-(4-bromophenyl)-N-(4-methylphenyl)amino)-phenyl-)-2,1,3-benzo Synthesis of Thiadiazoles

[0026] Under the protection of nitrogen atmosphere, 4,7-bis(4-(N-phenyl-N-(4-methylphenyl)amino)-phenyl-)-2,1,3-benzothiadi Azole (0.651g, 1mmol) was dissolved in chloroform, aluminum trichloride was added, and then tetrabutylammonium tribromide (1.446g, 3mmol) was added in batches several times, and reaction was carried out for 30 minutes after adding, and then the reaction mixture was used Washed once with aqueous sodium bisulfite solution, washed several times with water, dried, concentrated, and separated by column to obtain pure intermediate product 4,7-bis(4-(N-(4-bromophenyl)-N-(4-methylbenzene Base) amino)-phenyl-)-2,1,3-benzothiadiazole 0.751g, yield 93%.

Embodiment 3

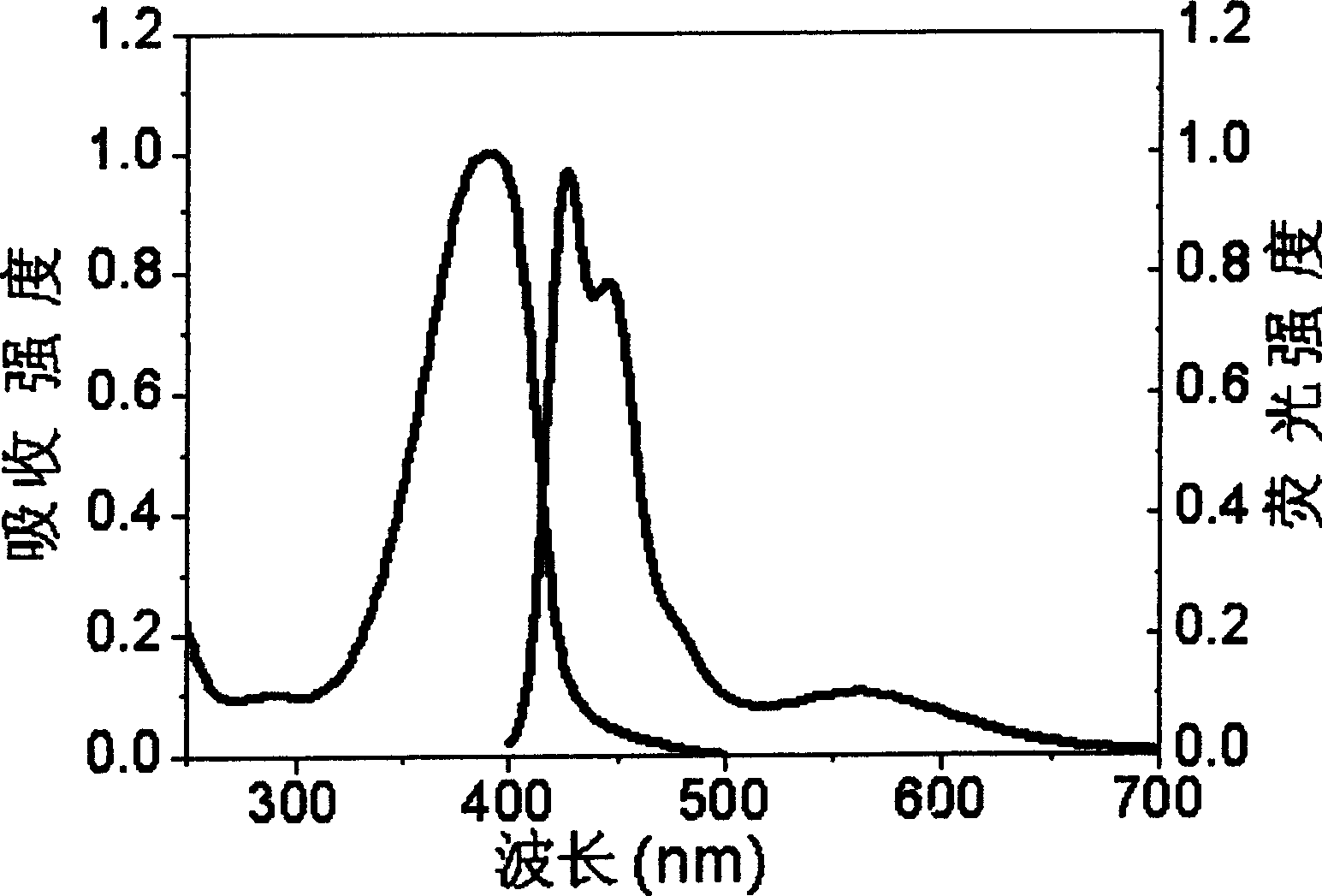

[0027] Example 3: Synthesis of two-color white light polymer material P1 (structural formula shown below)

[0028]

[0029]Under nitrogen protection, 9,9-dioctyl-2,7-dibromofluorene (0.2740g, 0.4997mmol), 9,9-dioctyl-2,7-(trimethylene Borate)fluorene (0.2792g, 0.5mmol), 4,7-bis(4-(N-(4-bromophenyl)-N-(4-methylphenyl)amino)-phenyl- )-2,1,3-benzothiadiazole (0.0005g, 0.0006mmol), 2M potassium carbonate aqueous solution (2mL), toluene (10mL), methyl trioctyl ammonium chloride (0.13g) mixture, in React at 80°C for ten minutes, then add tetrakis(triphenylphosphine)palladium into the reaction bottle, stir at 90°C for 48 hours, then stir at 60°C for 24 hours. The reaction mixture was dissolved in chloroform, washed several times with water, dried, concentrated, and then settled three times with methanol. The product was placed in a Soxhlet extractor and extracted with acetone for 24 hours. Then it was dissolved in chloroform, settled in methanol, and the product was vacuum-dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum brightness | aaaaa | aaaaa |

| Lumen efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com