Perphenazine orally disintegrating tablet and preparation method thereof

A technology of orally disintegrating tablets and disintegrants, applied in pill delivery, neurological diseases, drug combinations, etc., can solve problems such as slow dissolution rate, unloaded, affecting drug absorption and bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

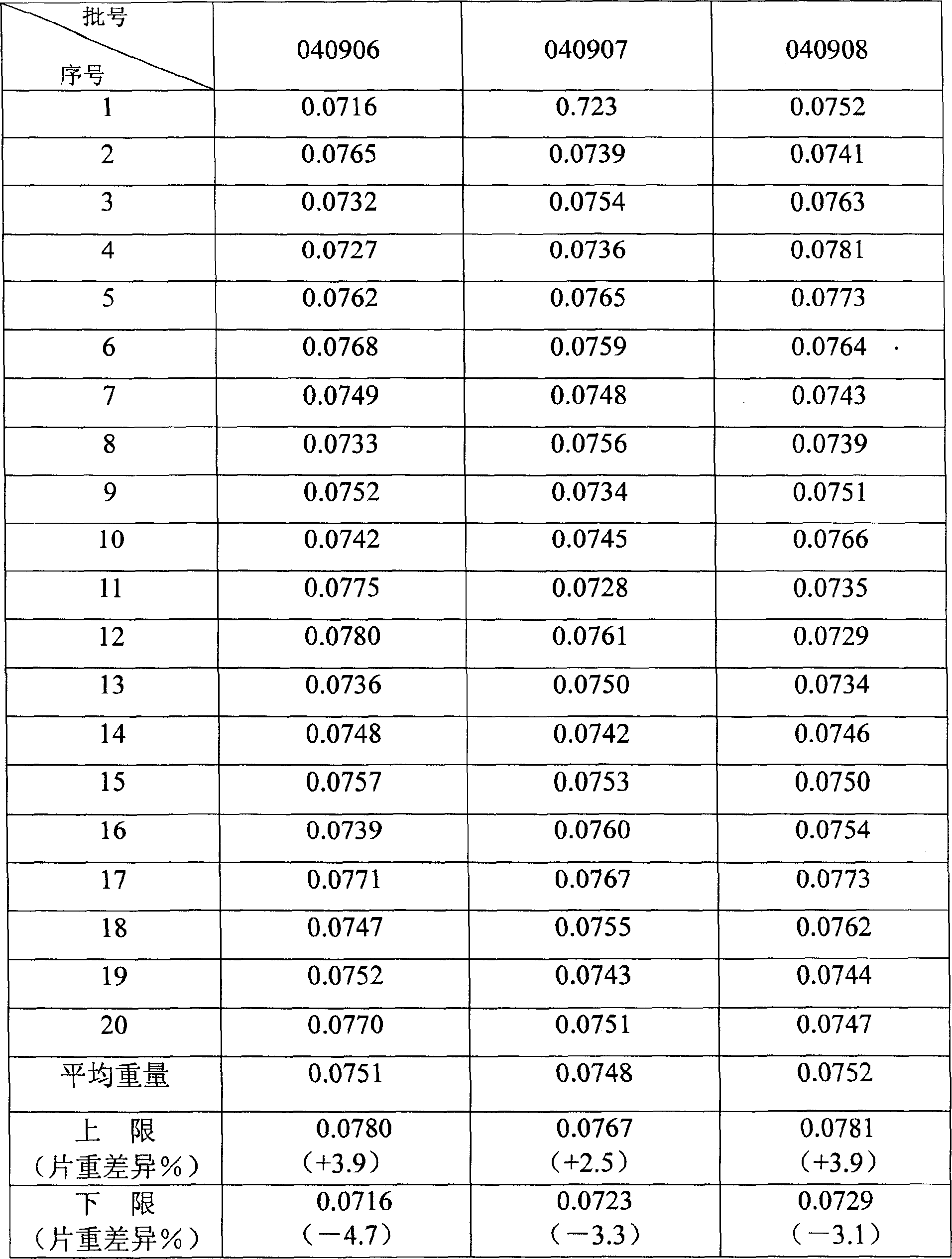

Image

Examples

Embodiment 1

[0042] Perphenazine 4.0g

[0043] Sodium carboxymethyl starch 13.1g

[0044] Microcrystalline Cellulose 27.3g

[0045] Micronized silica gel 3.6g

[0046] Magnesium stearate 0.7g

[0047] Aspartame 0.1g

[0048] Made into 1000 pieces

[0049] Perphenazine, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel, magnesium stearate, etc. are all passed through a 100-mesh sieve.

[0050] Weigh 4.0 grams of perphenazine, first mix with 13.1 grams of sodium carboxymethyl starch in equal amounts, then add 27.3 grams of microcrystalline cellulose and mix thoroughly, then add 3.6 grams of micropowder silica gel, 0.7 grams of stearic acid Magnesium and aspartame 0.1 g, mix well. Detect the percentage content of perphenazine in the mixed powder, calculate the weight of the tablet, and press it into a tablet. In this way, 1000 perphenazine orally disintegrating tablets can be pressed out.

[0051] Its disintegration time is...

Embodiment 2

[0053] Perphenazine 9.0g

[0054] Sodium carboxymethyl starch 18.0g

[0055] Microcrystalline Cellulose 45.0g

[0056] Micronized silica gel 4.5g

[0057] Magnesium stearate 0.5g

[0058] Aspartame 0.1g

[0059] Made into 1000 pieces

[0060] Perphenazine, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel, magnesium stearate, etc. are all passed through a 100-mesh sieve.

[0061] Weigh 9.0 grams of perphenazine, first mix with 18.0 grams of sodium carboxymethyl starch in equal increments, then add 45.0 grams of microcrystalline cellulose and mix thoroughly, then add 4.5 grams of micropowder silica gel, 0.5 grams of stearic acid Magnesium and aspartame 0.1 g, mix well. Detect the percentage content of perphenazine in the mixed powder, calculate the weight of the tablet, and press it into a tablet. In this way, 1000 perphenazine orally disintegrating tablets can be pressed out.

[0062] Its disintegration ...

Embodiment 3

[0065] Perphenazine 6.0g

[0066] Sodium carboxymethyl starch 23.0g

[0067] Microcrystalline Cellulose 57.0g

[0068] Micronized silica gel 5.1g

[0069] Magnesium stearate 0.9g

[0070] Aspartame 0.3g

[0071] Made into 1000 pieces

[0072] Perphenazine, microcrystalline cellulose, sodium carboxymethyl starch, micropowder silica gel, magnesium stearate, etc. are all passed through a 100-mesh sieve.

[0073] Weigh 6.0 grams of perphenazine, first mix with 23.0 grams of sodium carboxymethyl starch in equal increments, then add 57.0 grams of microcrystalline cellulose and mix thoroughly, then add 5.1 grams of micropowder silica gel, 0.9 grams of stearic acid Magnesium and aspartame 0.3 g, mix well. Detect the percentage content of perphenazine in the mixed powder, calculate the weight of the tablet, and press it into a tablet. In this way, 1000 perphenazine orally disintegrating tablets can be pressed out.

[0074] Its disintegration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com