Sludge outer circulation type sewage treatment method of denitrifying and recovering phosphor using composite membrane bioreactor

A membrane bioreactor, sewage treatment method technology, applied in sustainable biological treatment, aerobic process treatment and other directions, can solve the problems of high sewage treatment cost, low phosphorus removal efficiency, and high excess sludge output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

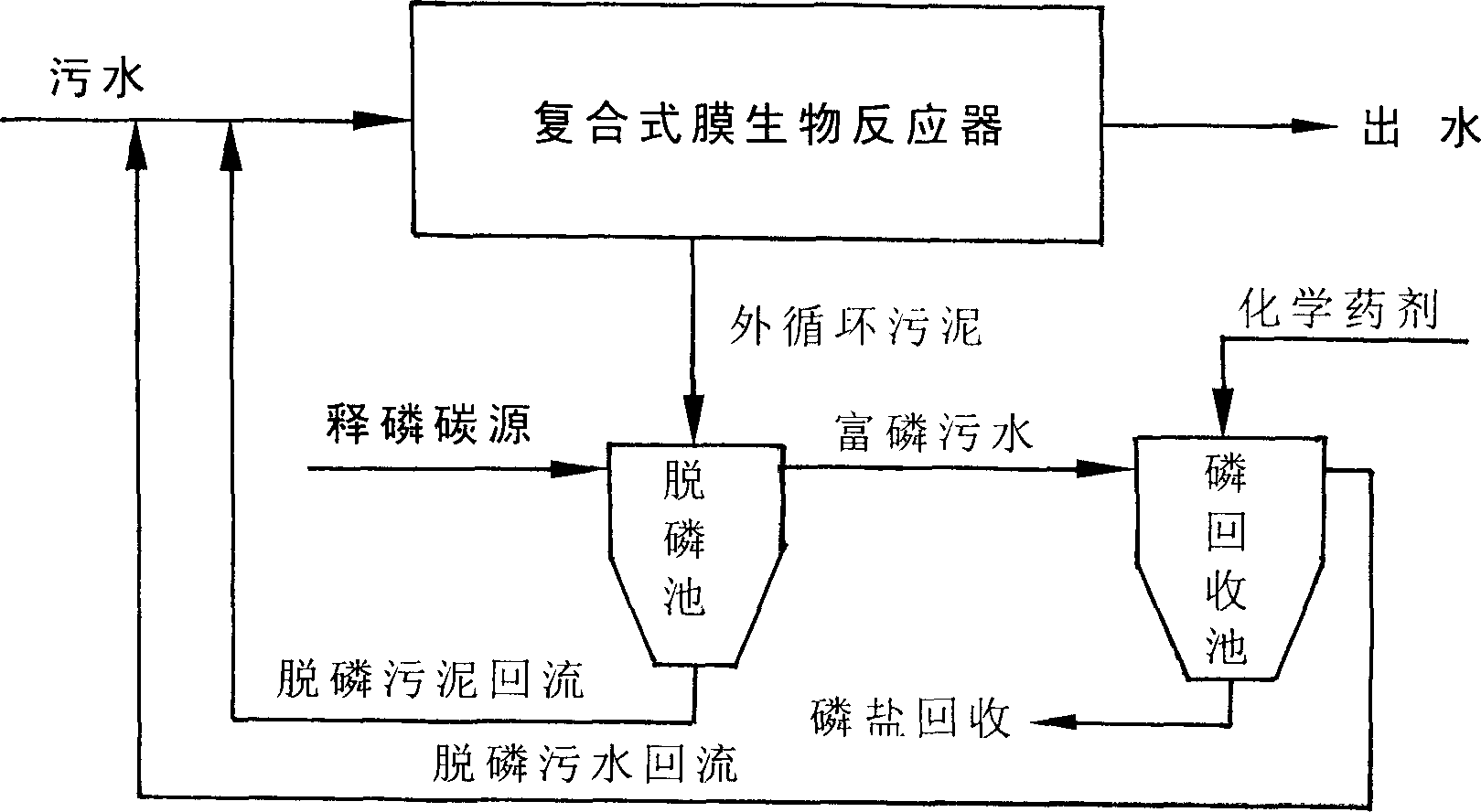

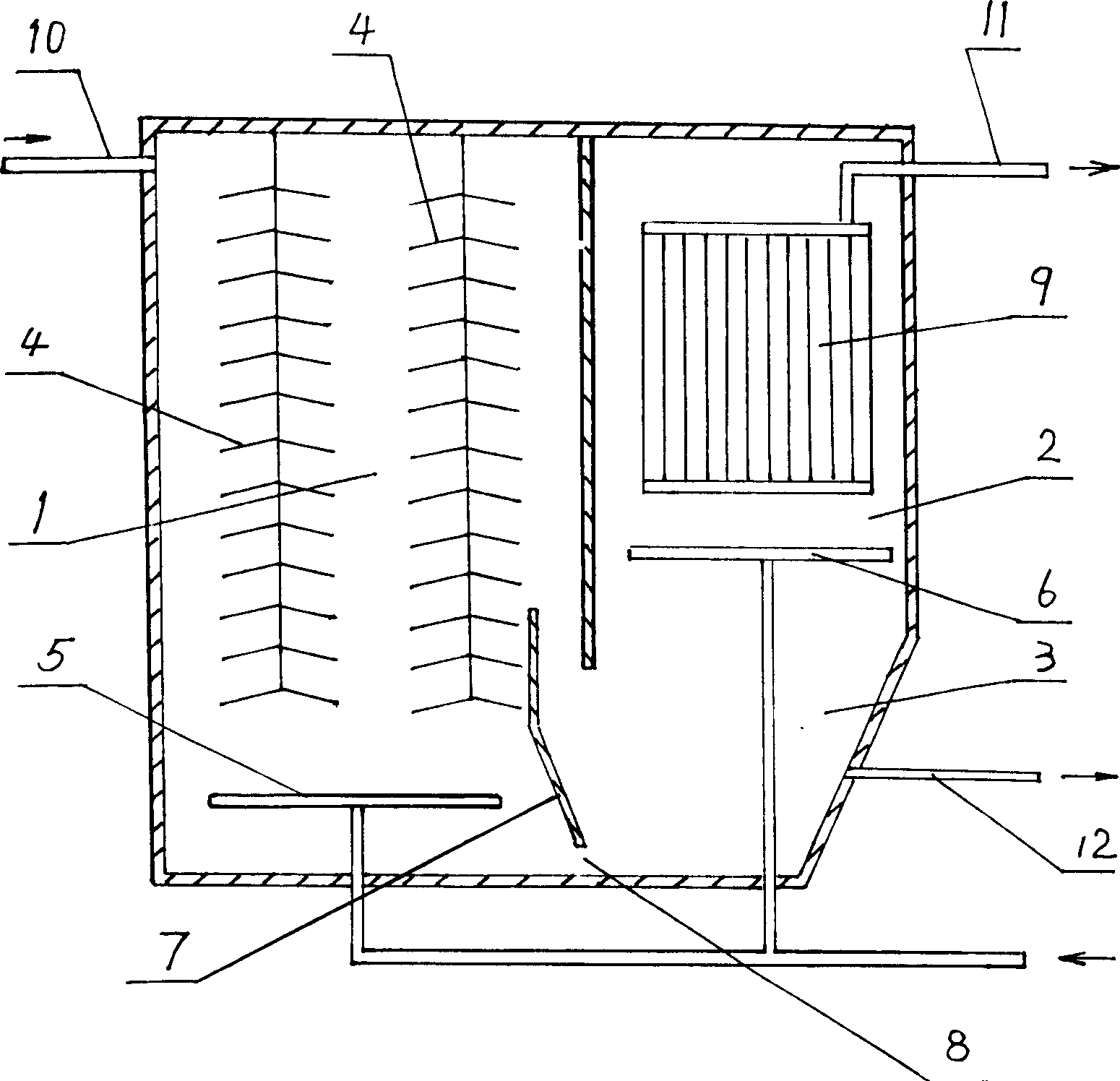

[0005] Specific implementation mode one: (see figure 2 , image 3 ) The technical scheme of this embodiment is achieved in this way: in the biofilm area 1 of the front section of the composite membrane bioreactor, suspended or suspended fillers are set, the biofilm is attached to the filler 4, and the sewage is in the biofilm area 1 The residence time is 3 to 5 hours, adjust the microporous aerator 5 to control the dissolved oxygen concentration in the biofilm area 1 between 0.5-1.5mg / L, and carry out simultaneous nitrification and denitrification denitrification; let the effluent of the biofilm area 1 flow from The bottom rectifying baffle 7 enters the sedimentation zone 3, and the surface load of the sedimentation zone 3 is 1.0m3 / m2.h. The mud-water separation is completed in the sedimentation zone 3, and part of the sediment at the bottom of the sedimentation zone 3 participates in the sludge external circulation for the release and recovery of phosphorus. The other part ...

specific Embodiment approach 2

[0006] Specific embodiment 2: In this embodiment, the chemical agents to recover phosphorus are aluminum salts, iron salts, magnesium salts or lime in chemical precipitants and their compound agents in any proportion. Other methods and specific

[0007] Embodiment 1 is the same.

specific Embodiment approach 3

[0008] Embodiment 3: In this embodiment, lime is used as a chemical precipitant, and the dosage of lime is enough to make the pH value of the sewage reach 10.1-10.6. Other methods are the same as in the first embodiment. The experimental results show that when lime is used as a chemical precipitant, the dosage of lime is related to the alkalinity in the sewage, and has nothing to do with the concentration of phosphorus in the sewage. When lime is added until the pH value of the sewage reaches about 10.4, the phosphorus recovery effect is the best .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com