Polyhedral crystalline copper powder and production thereof

A polyhedron and copper powder technology is applied in the field of crystalline copper powder and its preparation, as well as in the field of preparation of micron copper powder. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Dissolve 9.60g of ascorbic acid, 2.75g of sodium hydroxide, 12.50g of sodium acetate and 1.0g of gum arabic in 50ml of deionized water, stir at room temperature for 30min, raise the solution to 60°C, and then add 10ml of 25-28% ammonia water. 8.50 g of copper chloride dihydrate was dissolved in 30 ml of deionized water, and the temperature of the solution was also raised to 60° C. Add the copper chloride aqueous solution into the rapidly stirred mixed solution containing ascorbic acid, and react for 30 minutes. The resulting copper powder precipitate was centrifuged, washed three times with deionized water, washed twice with ethanol, and finally vacuum-dried at 60°C. The dried copper powder is bright pink with strong metallic luster.

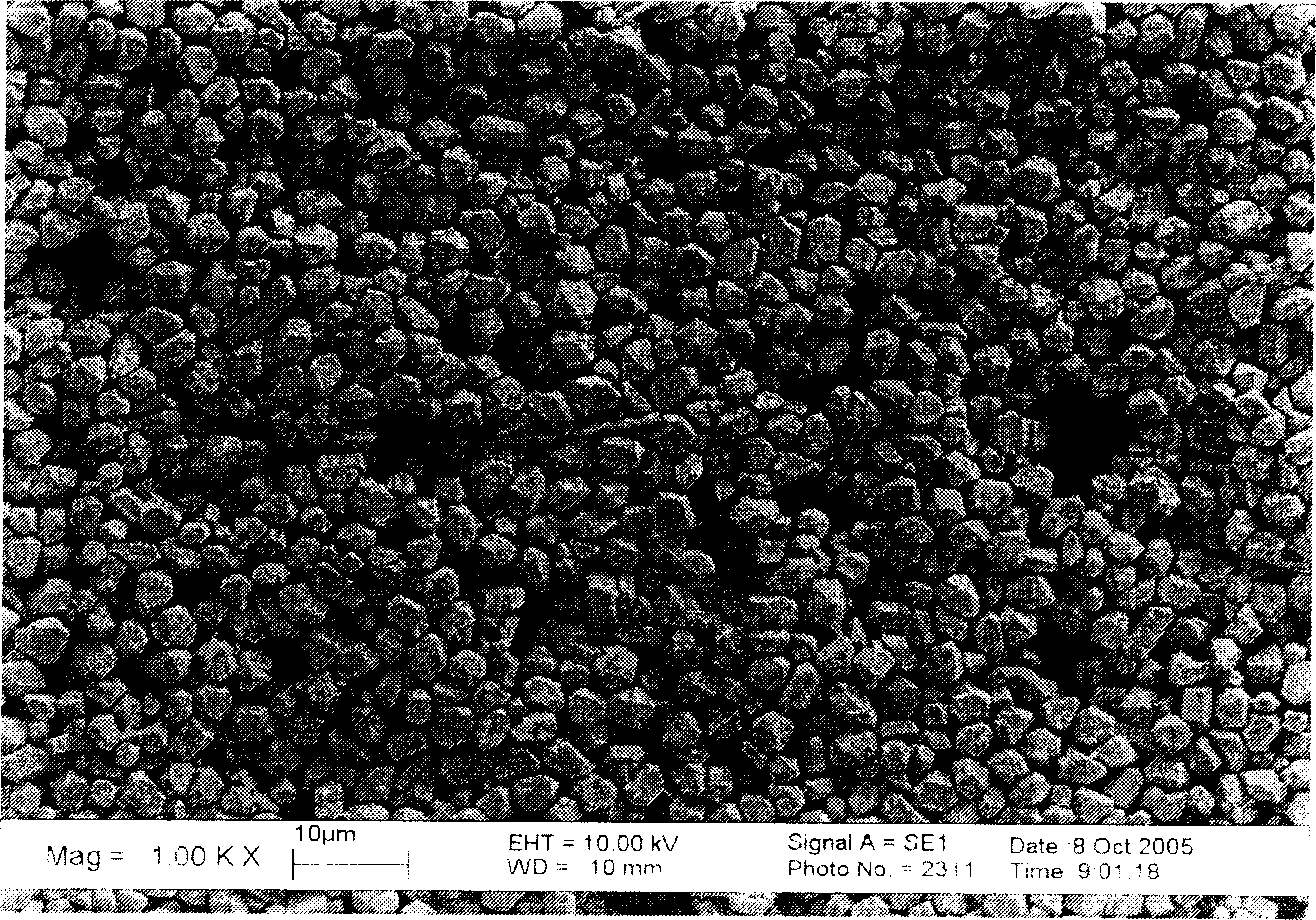

[0025] Such as figure 1 As shown, the morphology of the prepared copper powder was observed with a scanning electron microscope, and it was found that the copper powder was in the shape of a polyhedron, with obvious crystal edges on a s...

Embodiment 2

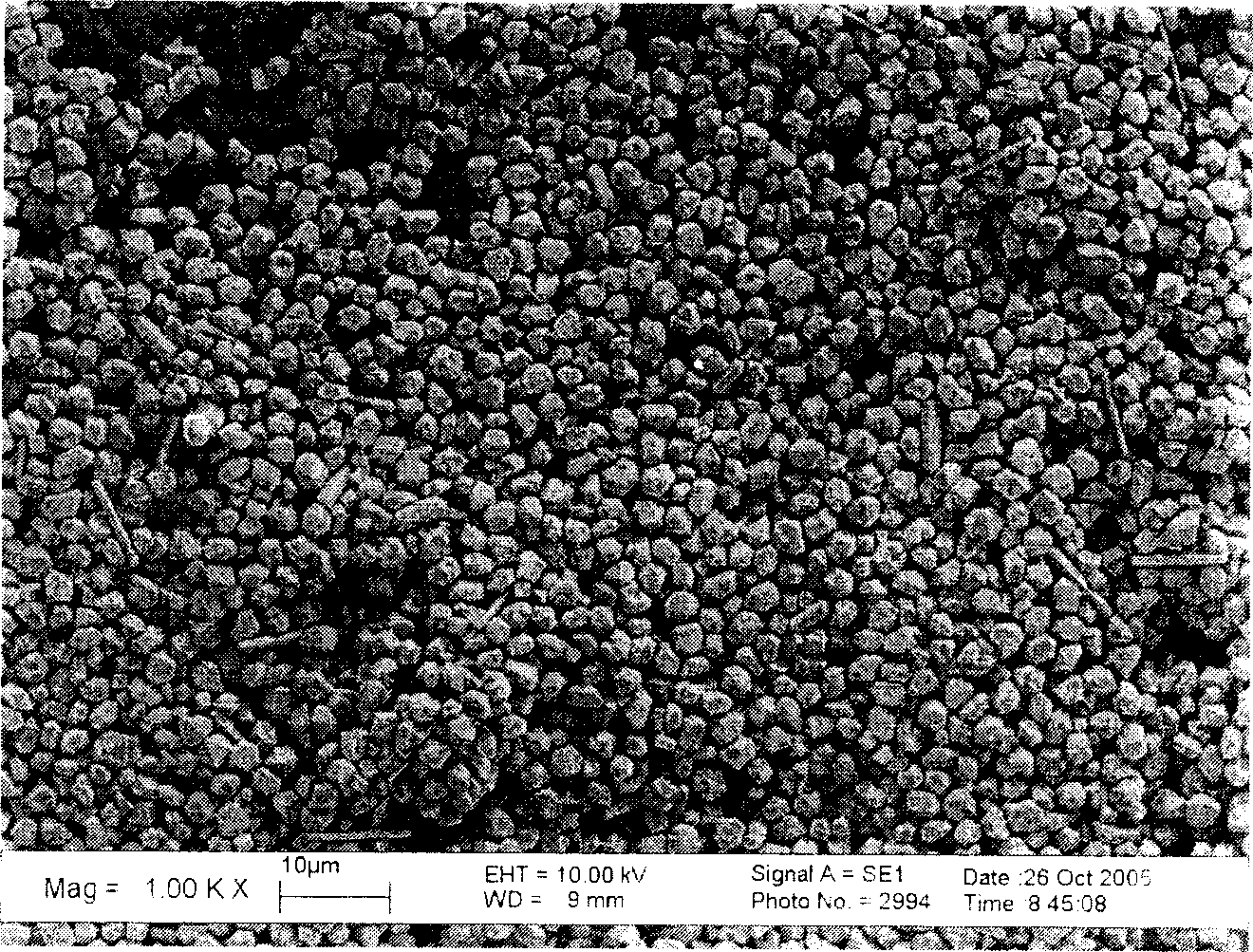

[0027] Change the consumption of dispersant gum arabic into 1.5g, sodium hydroxide consumption into 3.0g, all the other conditions are with embodiment 1. The prepared copper powder is in the shape of a polyhedron, with obvious crystalline surfaces on a single particle; the particles are well dispersed without agglomeration; the particle size distribution ranges from 1.4 to 3.0 μm, most of which are concentrated in the range of 2.1 to 2.6 μm, and the average particle size is 2.3 μm.

Embodiment 3

[0029] Dissolve 19.2g of ascorbic acid, 5.5g of sodium hydroxide, 12.50g of sodium acetate and 2.5g of gum arabic in 50ml of deionized water, stir at room temperature for 30min, raise the solution to 40°C, and then add 25-28% ammonia water 20ml. 17.0 g of copper chloride dihydrate was dissolved in 30 ml of deionized water, and the temperature of the solution was also raised to 40° C. Add the copper chloride aqueous solution into the rapidly stirred ascorbic acid solution, and react for 30 minutes. The prepared copper powder is multifaceted, and the particle size distribution range is 3.5-5.0 μm

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com