Hydrophilous slurry additive with mediben lignin and production thereof

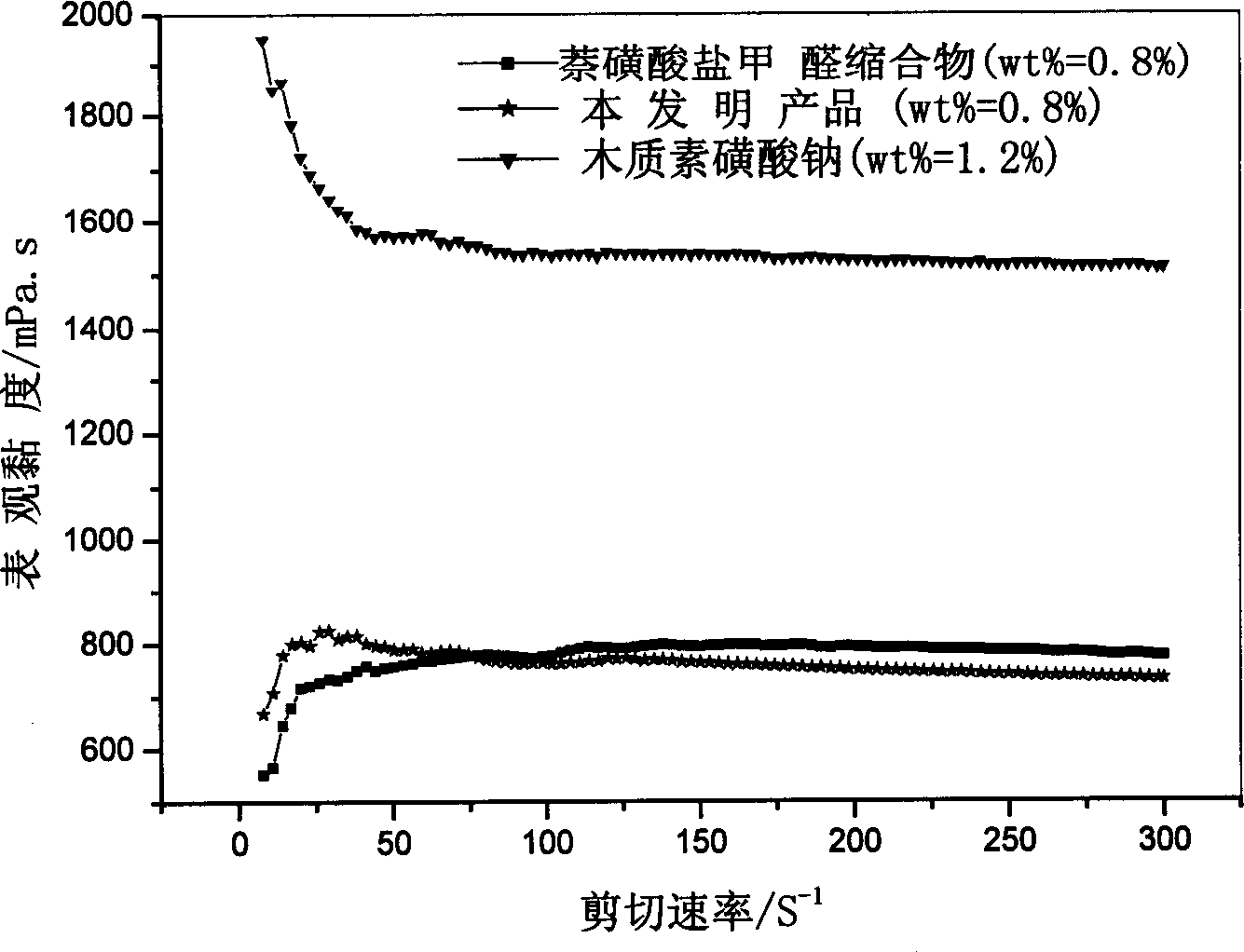

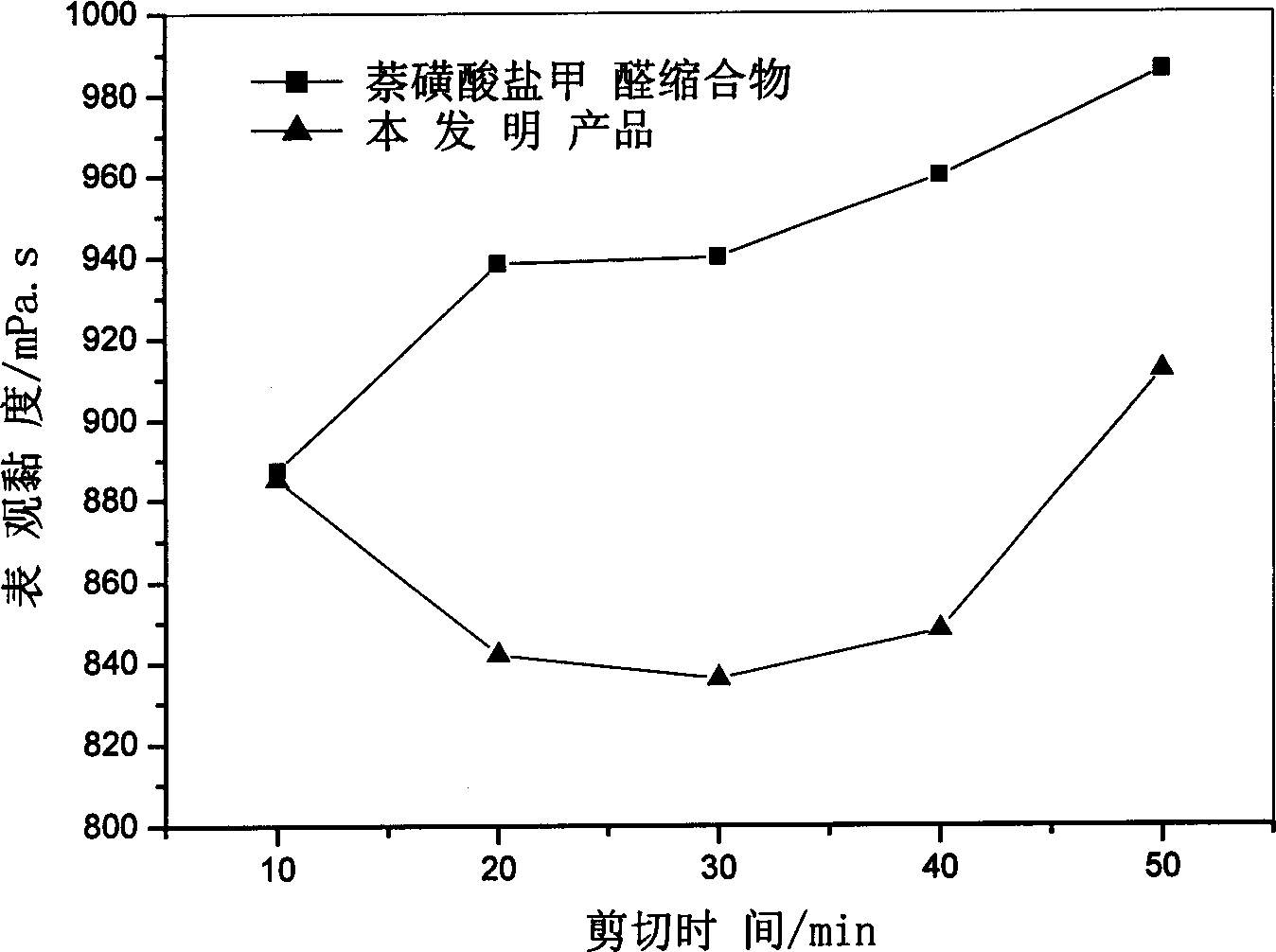

A wheat straw alkali lignin and coal-water slurry technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of good dispersion viscosity reduction performance, low additive efficiency, poor dispersion viscosity reduction performance, etc. Excellent viscosity, low production cost, improved dispersion and viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 100g of dry wheatgrass alkali lignin powder, add 150g of water, and add NaOH aqueous solution with a mass concentration of 20% to adjust the pH value to 9, heat to a certain operating temperature while stirring, and the operating temperature is controlled at 90°C. Add 20g of formaldehyde for methylolation reaction for 1 hour; take 60g of the mixture of sodium metabisulfite and sodium bisulfite, add 100g of water and stir to dissolve, heat up to 45°C, add 40g of acetylacetone, and react for 30 minutes; The reaction intermediates were mixed, and adding mass concentration while stirring was 50% H 2 SO 4 The pH value of the aqueous solution was adjusted to 5, and the temperature was raised to 90° C. During this process, 20 g of formaldehyde was added dropwise to carry out polycondensation reaction, and the reaction was carried out for 3 hours. After cooling, the high-efficiency coal-water slurry additive liquid product can be obtained, and then the powder product can ...

Embodiment 2

[0035] Take 100g of dried wheatgrass alkali lignin powder, add 200g of water, and add 20% NaOH aqueous solution to adjust the pH value to 9.5, and heat to a certain operating temperature while stirring, and the operating temperature is controlled at 85 ° C. During this process, drop Add 30g of glyoxal for methylolation reaction for 1.5 hours; take 40g of sodium sulfite, add 120g of water and stir to dissolve, heat up to 50°C, add 30g of ketene, and react for 30 minutes; mix the two reaction intermediates obtained above, and Add dropwise H2O with a mass concentration of 50% while stirring 2 SO 4The pH value of the aqueous solution was adjusted to 6, and the temperature was raised to 85°C. During this process, 10 g of glyoxal was added dropwise to carry out polycondensation reaction, and the reaction lasted for 3.5 hours. After cooling, the high-efficiency coal-water slurry additive liquid product can be obtained, and then the powder product can be obtained after drying.

Embodiment 3

[0037] Take 100g of dry wheatgrass alkali lignin powder, add 180g of water, and add NaOH aqueous solution with a mass concentration of 20% to adjust the pH value to 9, heat to a certain operating temperature while stirring, and the operating temperature is controlled at 90 ° C. During this process, drop Add 30g of propionaldehyde for methylolation reaction for 1.5 hours; take 30g of sodium metabisulfite, add 150g of water and stir to dissolve, heat up to 45°C, add 45g of a mixture of cyclohexanone and acetylacetone, and react for 35 minutes; The reaction intermediates were mixed, and while stirring, the mass concentration of 50% H was added dropwise. 2 SO 4 The pH value of the aqueous solution was adjusted to 5, and the temperature was raised to 80° C. During this process, 20 g of a mixture of formaldehyde and propionaldehyde was added dropwise to carry out polycondensation reaction for 4 hours. After cooling, the high-efficiency coal-water slurry additive liquid product can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com