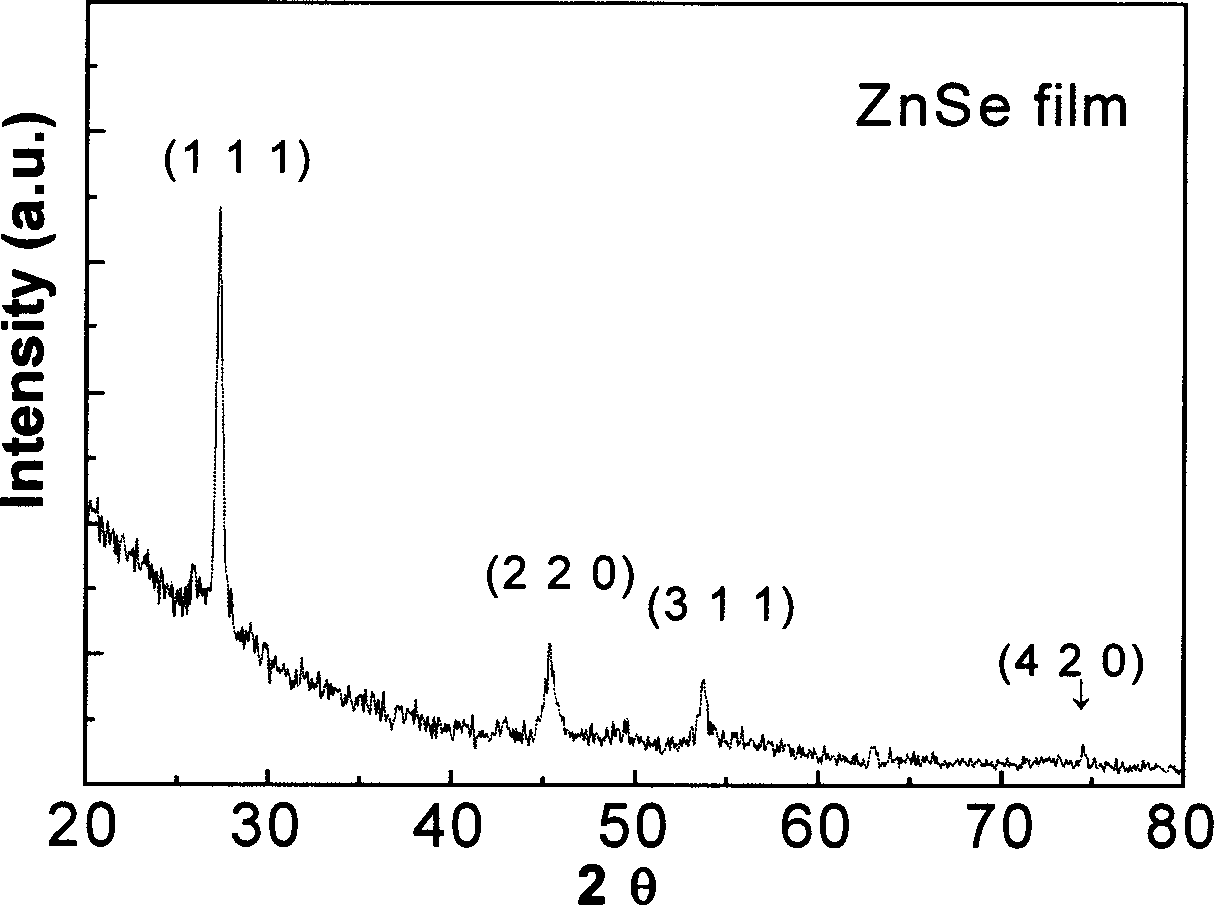

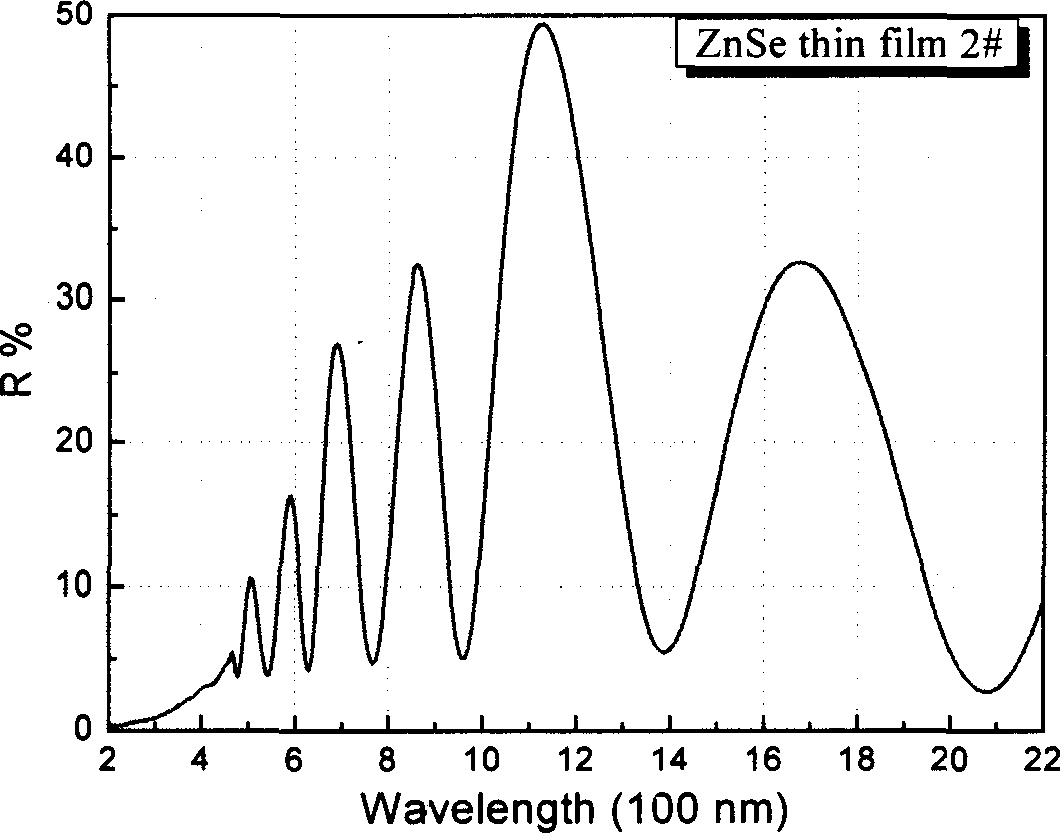

Process for rapid heating preparation of zinc selenide nano-crystal film by tubular gas furnace

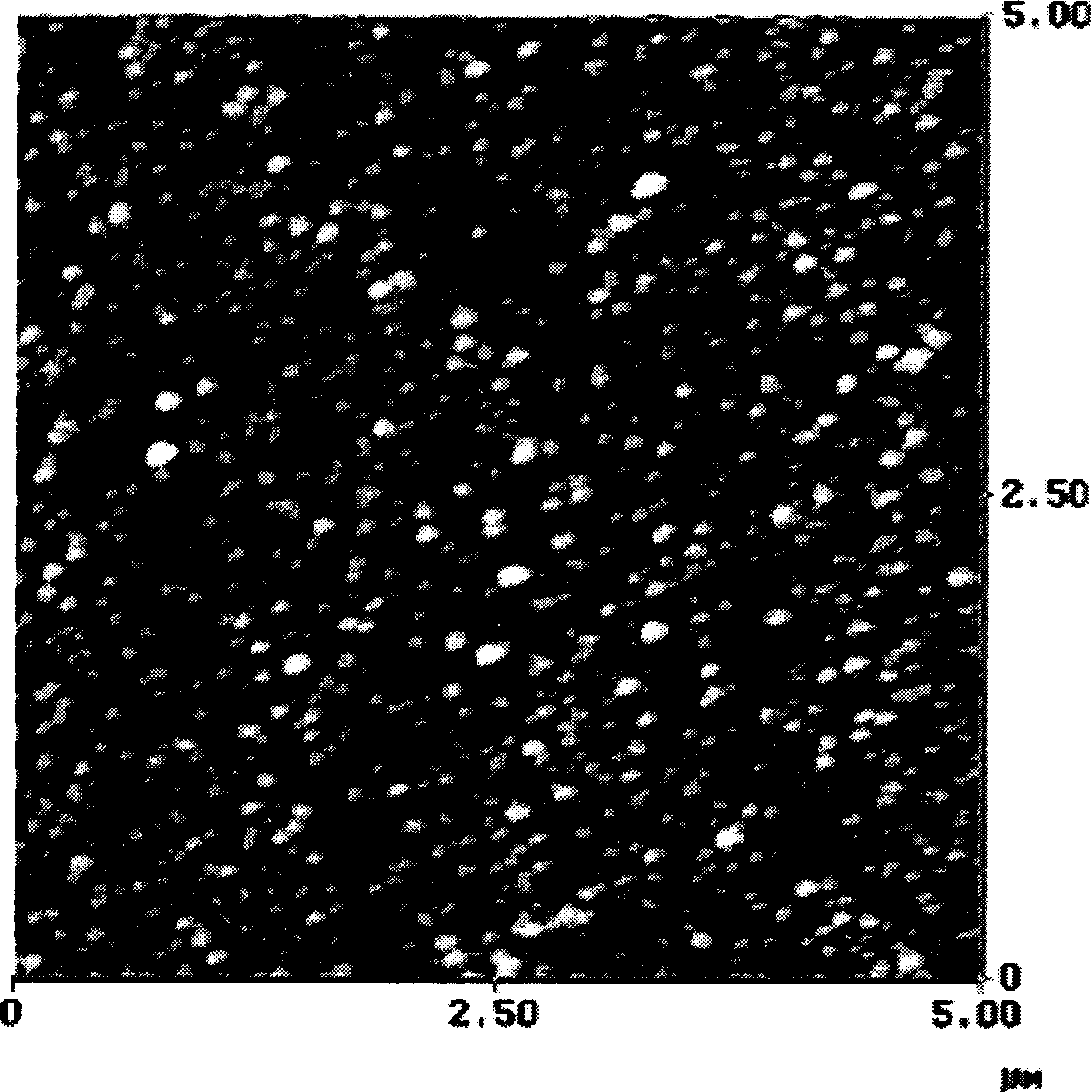

An atmosphere furnace, zinc selenide technology, applied in chemical instruments and methods, selenium/tellurium compounds, zinc compounds, etc., can solve the problems of expensive equipment, high requirements, difficult to obtain zinc selenide films, etc. The effect of stable degree and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, at first get elemental selenium powder and elemental zinc powder and mix by the molar ratio of 1: 1, then, the mixture is transferred in the high-energy ball mill jar that tungsten carbide is made, ball mills under the protection of nitrogen or argon, makes ZnSe powder The scale is 5 to 20 nanometers; take 0.2 grams of ZnSe nano powder and put it into the groove at one end of the quartz boat; place the silicon wafer or quartz substrate on the other side of the quartz boat, 15 cm away from the groove where the ZnSe nano powder is placed. 20 cm; then push the quartz boat into the quartz tube, and the pushing position should be appropriate (to ensure that the temperature of the powder is below 160°C when the tube furnace body is heated up to 800°C, and the ZnSe powder can be moved to the furnace body by pushing the quartz tube center); then cover the quartz tube, and check whether the joints of the quartz tube gas path of the tube furnace are in tight contact ...

Embodiment 2

[0018] Embodiment 2, at first get elemental selenium powder and elemental zinc powder and mix by the molar ratio of 1: 1, then, transfer the mixture into the high-energy ball mill jar made of tungsten carbide, ball mill under the protection of nitrogen or argon, make ZnSe The scale of powder is 5~20 nanometers; In the ZnSe nanometer powder, mix the Cr powder of its quality 1%-1‰, other steps are with embodiment 1, can obtain the ZnSe doped with Cr on deposition silicon chip or quartz glass substrate like this film.

Embodiment 3

[0019] Embodiment 3, at first get elemental selenium powder and elemental zinc powder and mix by the molar ratio of 1: 1, then, the mixture is transferred in the high-energy ball mill pot that is made of tungsten carbide, ball mills under the protection of nitrogen or argon, makes ZnSe The scale of powder is 5~20 nanometers; Get ZnSe (or Cr: ZnSe=1: 100-1000) nanopowder 0.2 gram, put into the groove of one end of quartz boat; On the other side, it is 15 cm to 20 cm away from the concave; then push the quartz boat into the quartz tube, and the pushing position is the same as in Example 1; then cover the quartz tube, and check the ports of the gas path of the tube furnace quartz tube Whether the contact is tight to prevent air leakage.

[0020] Start the heating program (30°C per minute until the temperature reaches 800°C, keep warm for one hour); during the heating process, turn on the air extractor to the maximum, observe the reading of the negative pressure gauge, when the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com