Nanometer titanium dioxide water pulp and its preparation method

A technology of nano-titanium dioxide and water-based slurry, which is applied in the direction of titanium oxide/hydroxide, etc., can solve the problems of poor dispersion stability and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

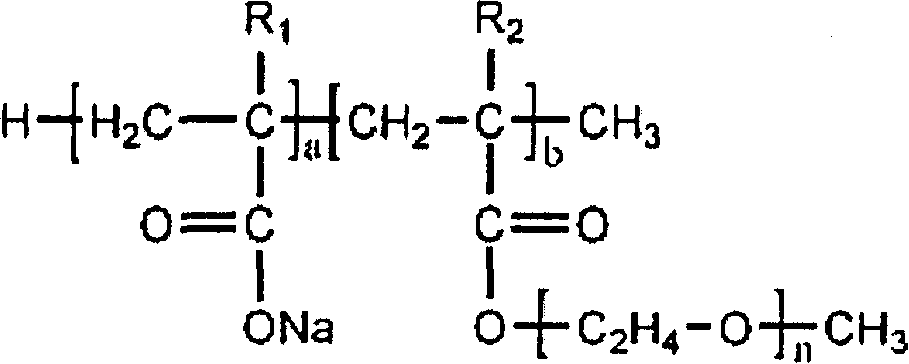

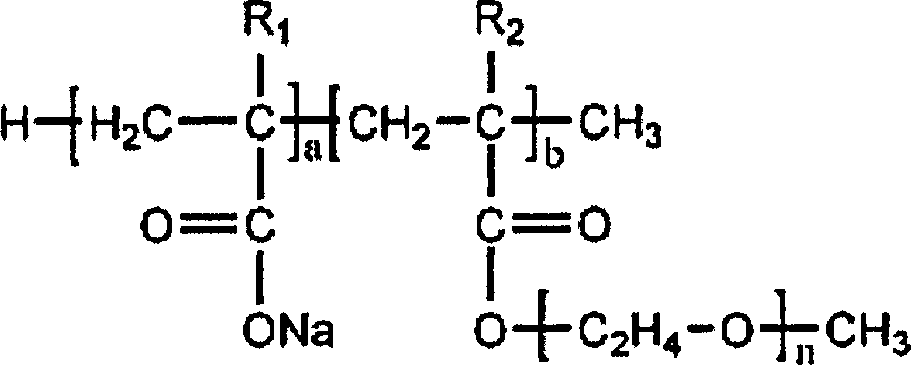

Method used

Image

Examples

Embodiment 1

[0047] Get commercially available anatase type nano-titanium dioxide (primary crystal grain average size is 20nm) 170g, put into 250g tap water, add the tensio-active agent CH-2B of 8.5g, add the sodium hydroxide solution that weight concentration is 30% to adjust Solution pH to 8.0, add 0.5g of HX-5010 water-based defoamer, add 15g of propylene glycol. Use a high-speed disperser to disperse (3000rpm) and disperse for 5 minutes, put the obtained pre-dispersed slurry with a solid content of titanium dioxide of 21.4% into a sand mill for 45 minutes (the diameter of the sanding disc is 40mm, and the rotation speed is 4000rpm). Add 250g of water and 0.5g of HX-5010 defoamer, and add 30% sodium hydroxide solution to adjust the pH of the solution to 8.0, and disperse at high speed for 5 minutes. Sanding again for 5 minutes, the nano-titanium dioxide water-based slurry of the present invention was obtained. Qualitative and quantitative methods were used to analyze and test, and the ...

Embodiment 2

[0049] Get 110kg of commercially available anatase nano-titanium dioxide (primary grain average size is 20nm), put into 250kg of water, add 19kg of acrylic acid copolymer coating agent, add the ammoniacal solution of weight concentration 20% to adjust the pH of the solution to 10.0, add 0.9kg of HX-5030 defoamer, add 18kg of propylene glycol. Disperse (1000rpm) with a high-speed disperser for 15 minutes, and the obtained titanium dioxide solid content is 26.9% of the pre-dispersed slurry with a flow rate of 5L / min into a 30L horizontal sand mill for sand grinding (equivalent to a grinding residence time of 6min) to complete First grind. Add 250kg of water, 0.9g of HX-5030 defoamer, add 20% ammonia solution by weight, adjust the pH of the solution to 10, and disperse at high speed for 5 minutes. Re-introduce the sand mill with a flow rate of 10 L / min (equivalent to a grinding time of 3 min) to complete the second grinding to obtain the nano-titanium dioxide aqueous slurry of t...

Embodiment 3

[0052] Get 210g of commercially available anatase nano-titanium dioxide (the average size of the original grain is 20nm), put it into 250g of tap water, add 10.5g of surface coating agent CH-18C, add 15g of propylene glycol and 0.5g of HX-5010 Water-based defoamer, adding 20% ammonia solution by weight to adjust the pH of the solution to 7.0. Disperse (3000rpm) with a high-speed disperser for 5 minutes, and then put the obtained pre-dispersed slurry with a solid content of titanium dioxide of 42.4% into a sand mill for 45 minutes (diameter of the sand grinding disc 40mm, rotating speed 4000rpm). Add 180g of water and 0.4g of HX-5010 water-based defoamer, and add 20% ammonia solution to adjust the pH of the solution to 7.0, and disperse at high speed for 10 minutes. Sanding again for 5 minutes, the nano-titanium dioxide water-based slurry of the present invention was obtained. Qualitative and quantitative methods were used to analyze and test, and the test data are shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com