Smokeless coal burning boiler and gas synthetizing equipment thereof

A technology for coal-fired boilers and synthesis equipment, applied in the field of boilers, can solve the problems of cumbersome operation, increased operating costs, complex systems, etc., and achieves the effects of reducing coal consumption, improving use efficiency and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

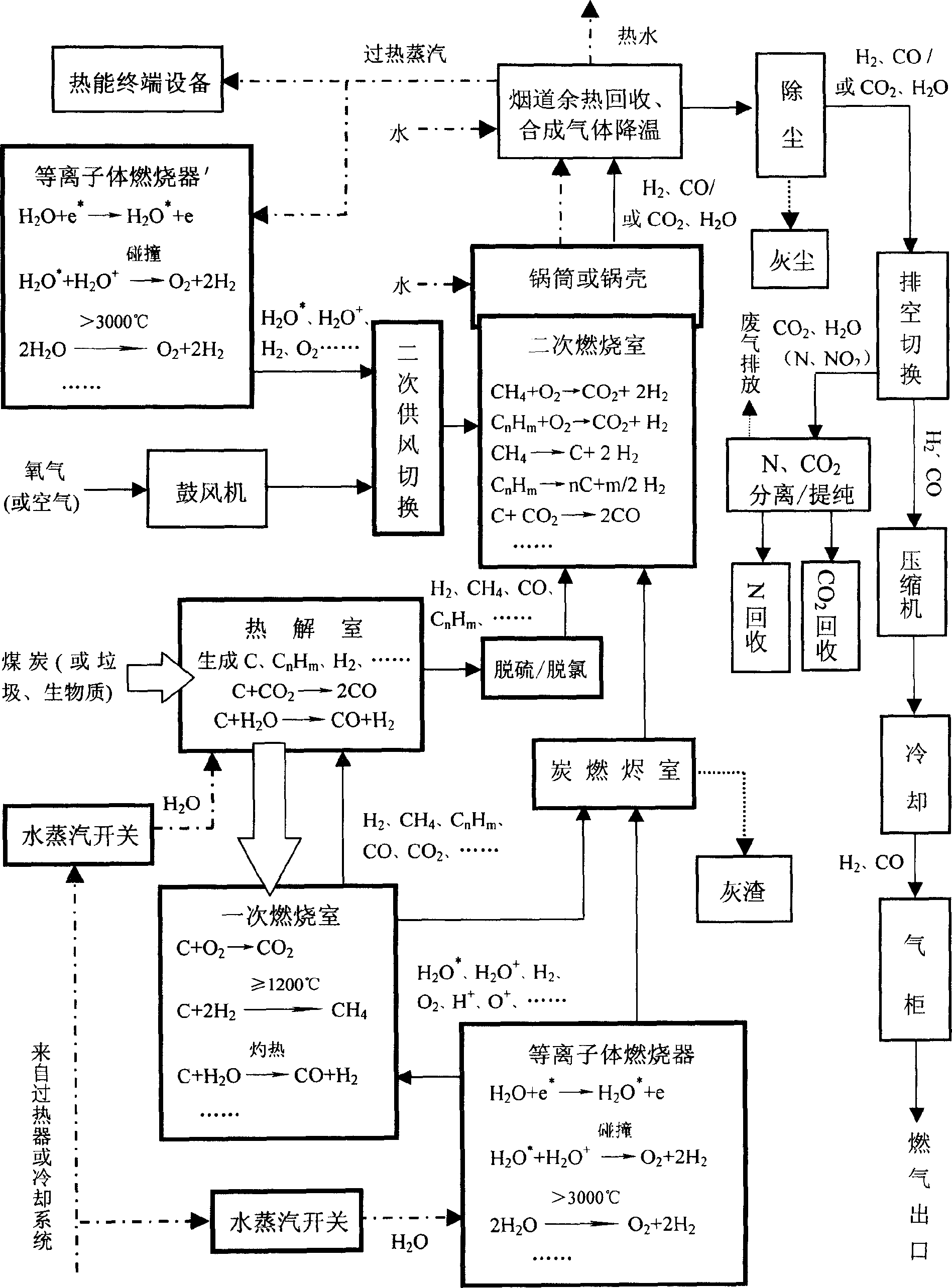

[0026] The preferred scheme of the present invention is as figure 1 As shown in the block diagram, the equipment is used in occasions where it is necessary to obtain heat energy to prepare hot water and heating gas, and to produce gas for cooking stoves and other heat energy equipment, such as hotels and restaurants. In this plan: the furnace is filled with coal (or garbage, biomass) fuel, the temperature of the primary combustion chamber has risen after the pre-combustion furnace, and when the combustion of coal reaches a stable state, the superheated water vapor is used as the working gas to enter the Plasma burner, under the action of electric field and electric arc, water molecules lose their outer electrons to form ions, which are decomposed into hydrogen and oxygen by collision with each other, and at the same time generate high temperature and chemical reactions:

[0027]

[0028]

[0029]

[0030]

[0031] ...

[0032]

[0033]

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap