Process for preparing N-formyl morpholine

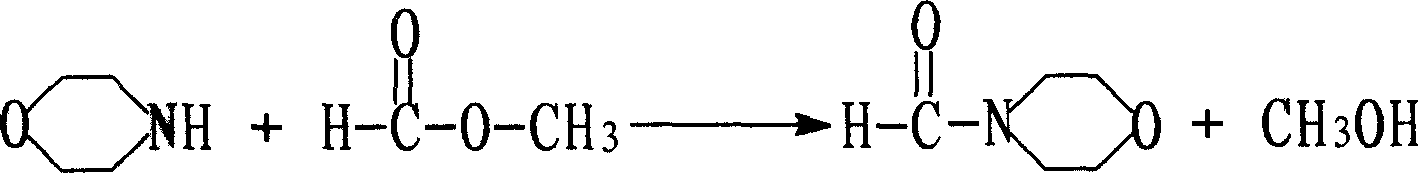

A technology of formylmorpholine and morpholine, which is applied in the field of solvent extraction in aromatics synthesis equipment, can solve the problems of expensive catalysts, high equipment requirements, and high prices, and achieve low production energy consumption, low equipment investment, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

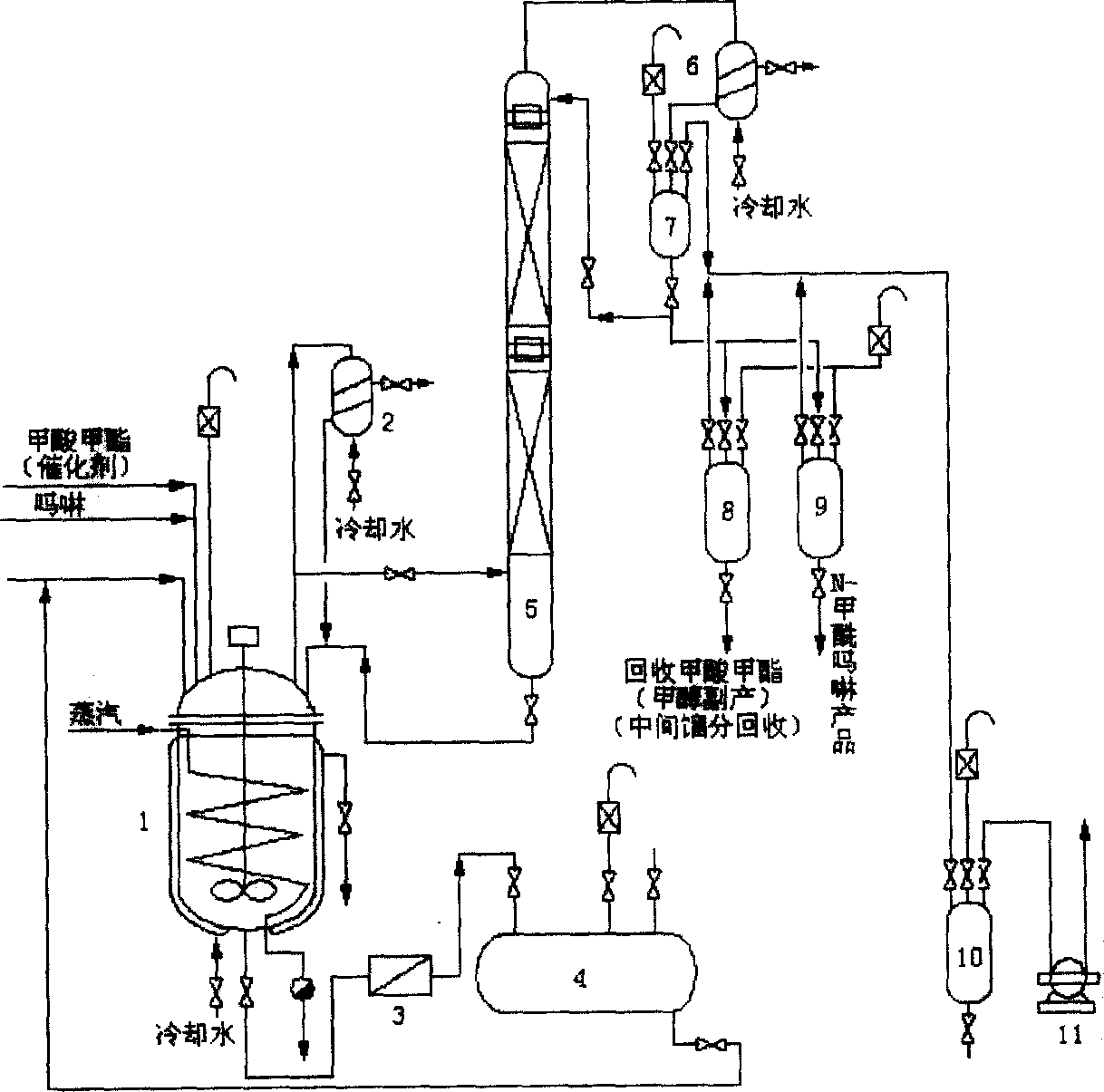

[0041] like figure 1 As shown, 1 stirring reactor; 2 reaction reflux condenser; 3 catalyst filter; 4 middle tank; 5 batch rectification tower; 6 return condenser; 7 reflux tank; Buffer tank; 11 vacuum pumps. Refer to the schematic diagram of the batch production process of N-formylmorpholine ( figure 1 ), add metered morpholine and transesterification catalyst in stirring reaction kettle 1, under vigorous stirring, slowly add metered methyl formate, control reaction temperature and pressure to reach required requirement, react certain time, obtain crude product .

[0042] The reaction kettle is used as a rectifying kettle at this time, and the heating coil inside the reaction kettle is used for heating, and a batch rectifying tower 5 (theoretical plate number: 35) is used in combination to carry out product separation.

[0043] The operating pressure of the methyl formate separation and recovery process is 0.2Mpa, the temperature of the reactor 1 is 68-82°C, and the methyl ...

Embodiment 6~10

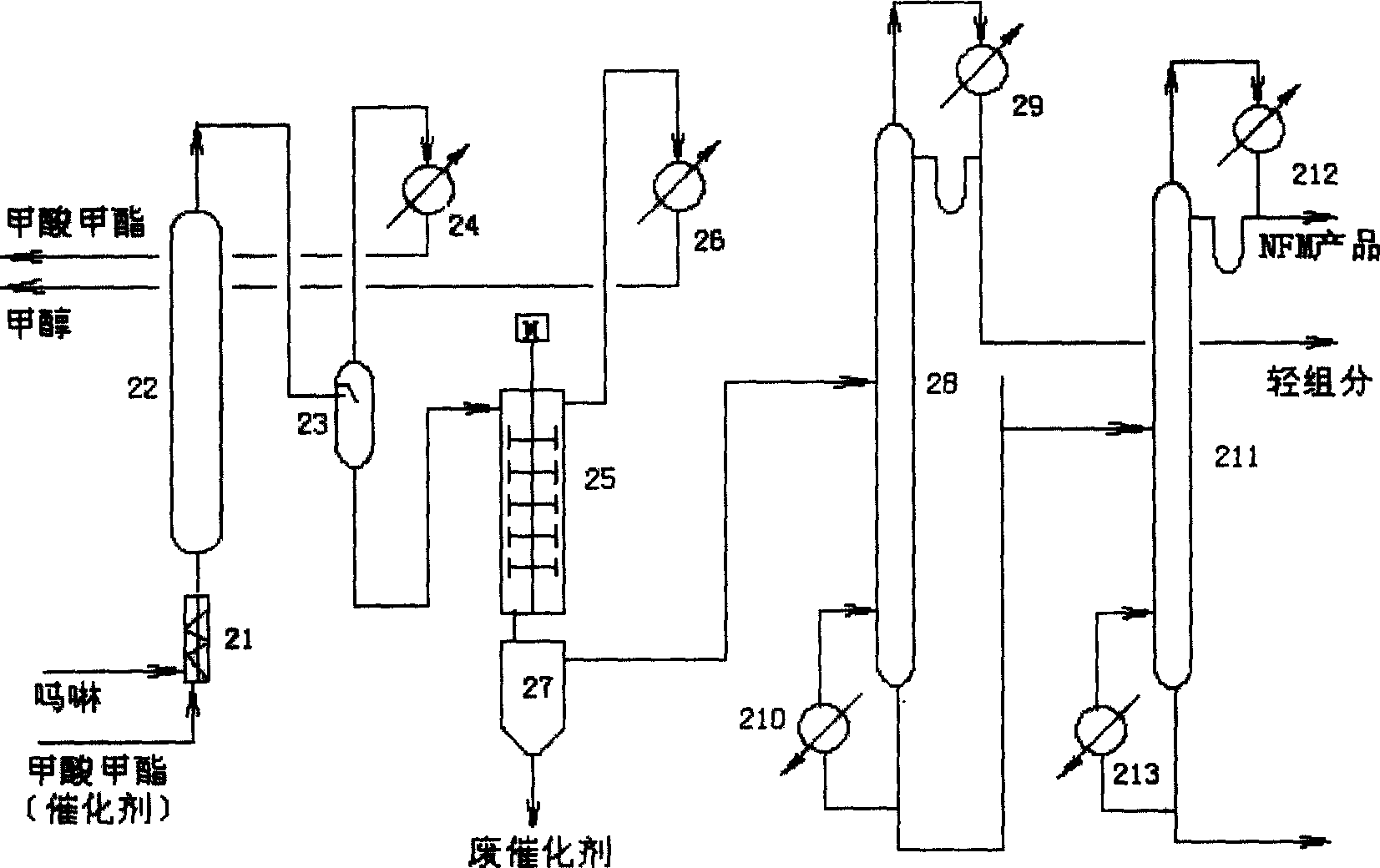

[0048] figure 2 21 static mixer; 22 reactor; 23 flash tank; 24 methyl formate condenser; 25 thin film evaporator; 26 methanol condenser; 27 catalyst settler (or filter); 28 light component tower; 29 light Tower condenser; 210 light tower reboiler; 211 vacuum product tower; 212 product tower condenser; 213 product tower reboiler. Refer to the schematic diagram of the continuous production process of N-formylmorpholine ( figure 2) Methyl formate and morpholine containing a prescribed amount of catalyzer are squeezed into the static mixer 21 with a metering pump respectively, and then enter the tubular reactor 22 (embodiment 6-7) or tower reactor 22 ( Examples 8-10) were reacted to obtain the crude product.

[0049] The crude product flowing out from the reactor enters the flash tank 23 for flash evaporation after the pressure is reduced to 0.15MPa through the throttle valve, and the gas phase part is methyl formate after being condensed, and the liquid phase enters the rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com