Metal oxide anode assembly for cathode protection of ship

A technology of cathodic protection and anode components, which is applied in the field of metal oxide anode components for ship cathodic protection, which can solve the problems of affecting the streamline of the hull, large protection current, and easy damage of the coating, so as to save precious metal resources, long service life, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

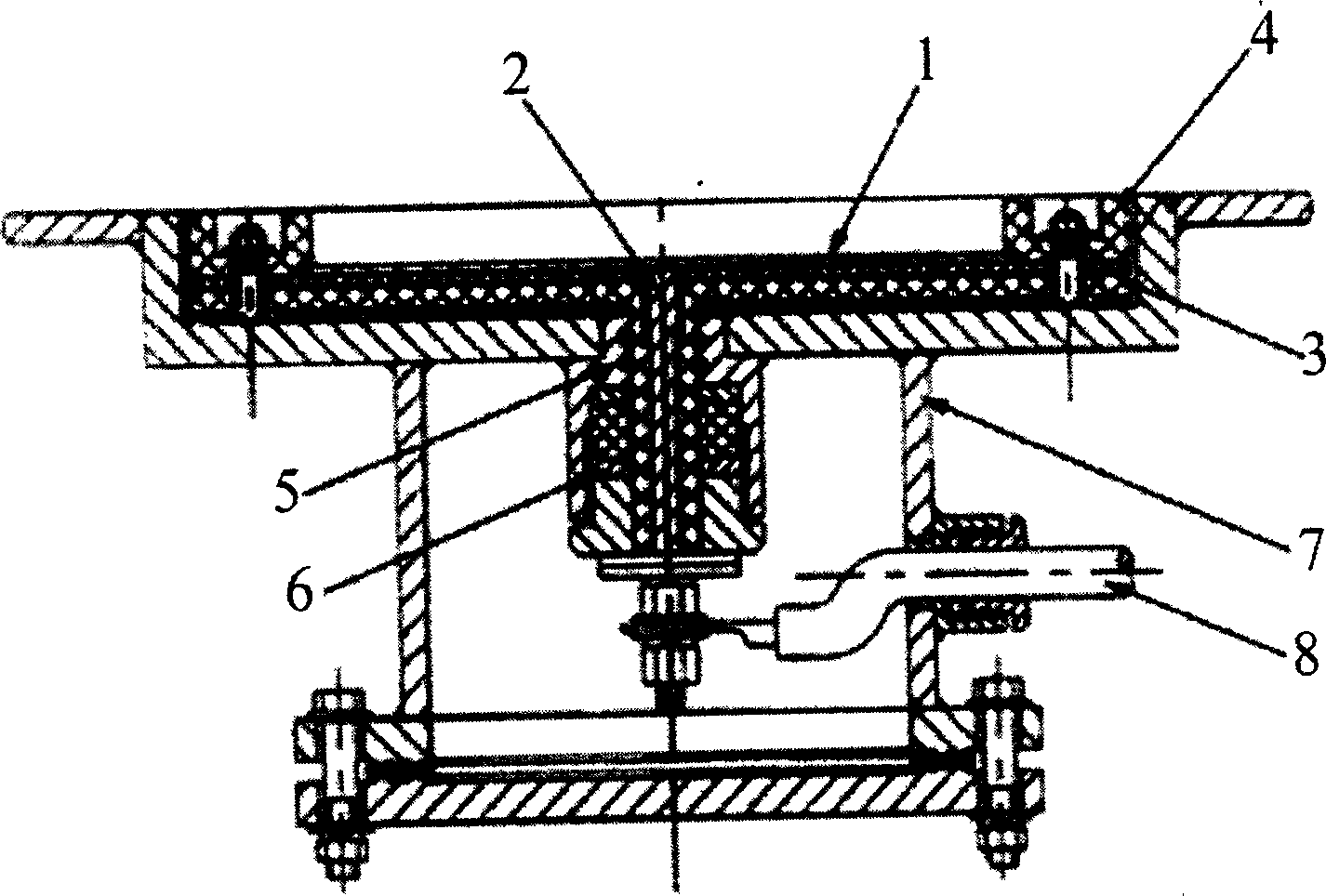

[0023]A titanium plate is used as the anode substrate, with a diameter of Φ300mm and a thickness of 10mm. A titanium conductive rod 2 with a diameter of 12mm is welded on the back, and the working surface of the anode body 1 is coated with ruthenium oxide, iridium oxide, titanium oxide, tantalum oxide, A mixed metal oxide conductive coating of tin oxide, wherein the content of ruthenium oxide and iridium oxide is 30% (mol). The anode bracket 3 is made of glass fiber reinforced epoxy resin composite material through compression molding. The anode body 1 is packaged in the molded anode bracket 3 with epoxy resin to make an anode assembly. The anode fixing frame 4 is made of polytetrafluoroethylene, the auxiliary anode assembly is installed in the pre-prepared groove at the stern of the hull, and fixed with 6 bolts. According to the amount of protection current required by the design, a total of 2 auxiliary anode assemblies are used, which are respectively installed on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com