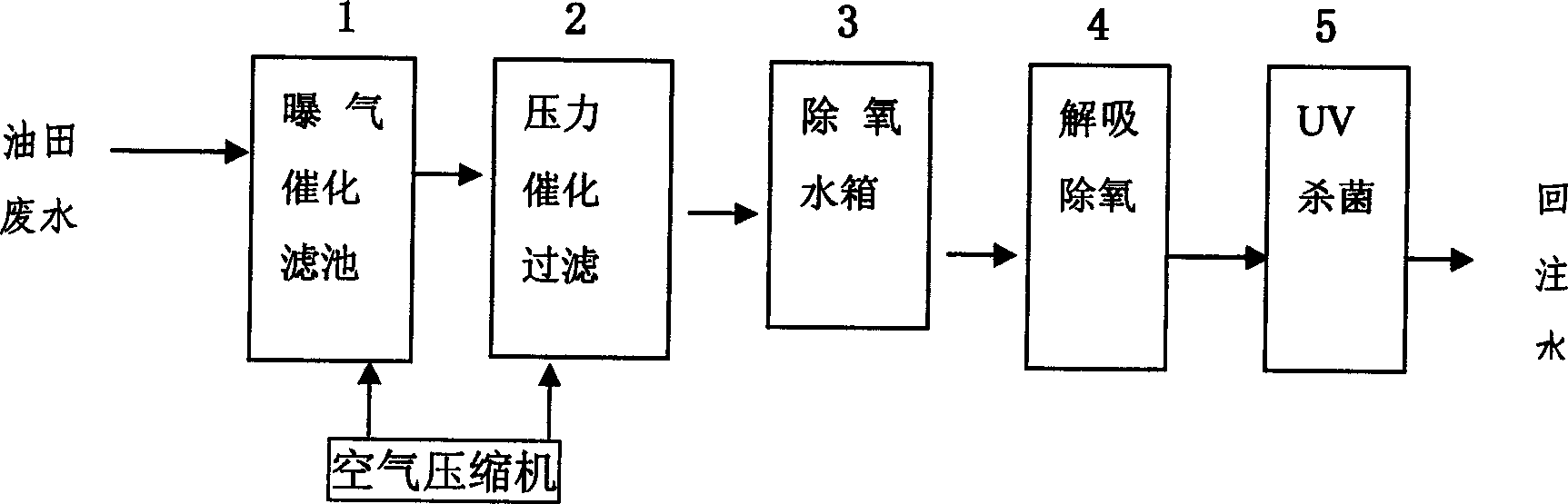

Method for treating oil-field waste-water refilling by catalytic oxygenation-desorption deaerization UV sterilization

A technology for deoxygenated water tanks and oil fields, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc. It can solve the problems of high operating costs, large dosage of chemicals, and long process, and achieve low operating costs. , long service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

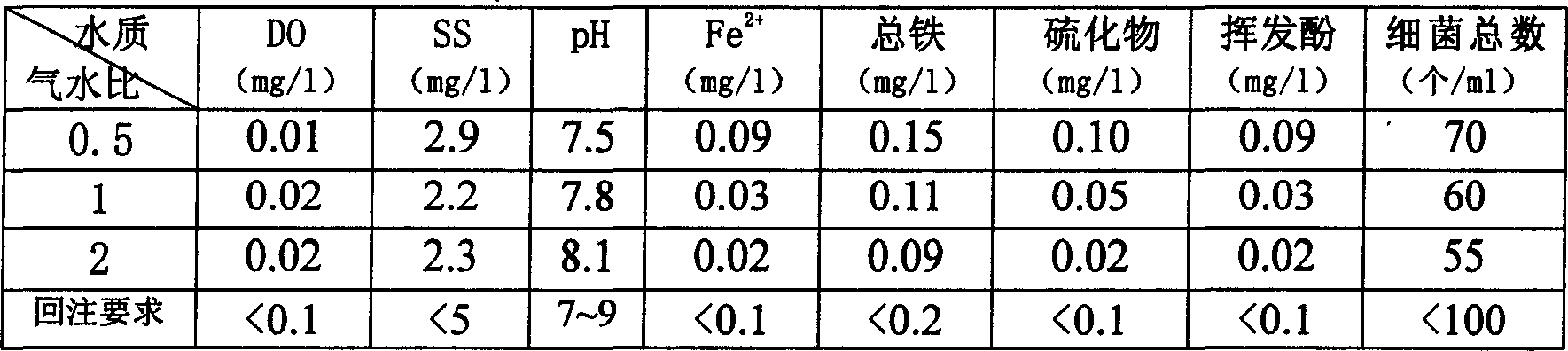

[0026] Embodiment 1: The gas-water ratio condition experiment of oilfield wastewater

[0027] In the aeration catalytic filter (1500×1000×2000mm) and pressure catalytic filter tank (Φ1200×2800mm) of the catalytic reactor made of stainless steel, two porous partitions are placed in parallel, and the filling accounts for 35% of the volume of the catalytic reactor Manganese sand, the aeration and catalytic reaction time is 5min, the reaction temperature is 45°C, the catalytic reaction pressure is 0.3mPa, the oxidation reaction time is 3 minutes, the silver-loaded activated carbon deoxidation catalytic reaction temperature is 250°C, and the desorption deaerator inlet pump pressure is 3mPa , under the conditions of deoxygenated water reflux 50% and UV sterilization, the water quality of raw water after precipitation treatment is petroleum 11.2mg / l, volatile phenol 7.1mg / l, sulfide 8.4mg / l, SS 10.7mg / l and Fe 2+ 3.9mg / l, and the catalytic treatment of wastewater under different rati...

Embodiment 2

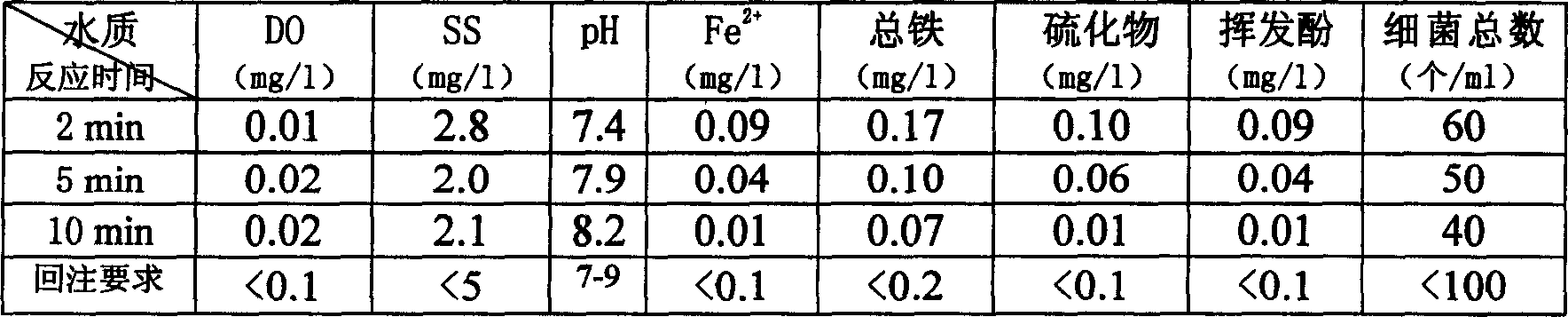

[0031] Embodiment 2: For the treatment time experiment of oilfield wastewater

[0032] In the aeration catalytic filter (1500×1000×2000mm) and pressure catalytic filter tank (Φ1200×2800mm) of the catalytic reactor made of stainless steel, two porous partitions are placed in parallel, and the filling accounts for 35% of the volume of the catalytic reactor manganese sand, the ratio of aeration gas to water is 1 / 1, the reaction temperature is 45°C, the catalytic reaction pressure is 0.3mPa, the oxidation reaction time is 3 minutes, the silver-loaded activated carbon deoxidation catalytic reaction temperature is 250°C, and the desorption deaerator inlet water pump pressure 3mPa, under the conditions of deoxygenated water reflux 50% and UV sterilization, the water quality of raw water after precipitation treatment is 11.2mg / l of petroleum, 7.1mg / l of volatile phenol, 8.4mg / l of sulfide, 10.7mg / l of SS and Fe 2+ 3.9mg / l, and the wastewater was treated under different aeration and ca...

Embodiment 3

[0036] Embodiment 3: the influence experiment of the polymer solution viscosity of sewage preparation

[0037] In the aeration catalytic filter (1500×1000×2000mm) and the pressure catalytic filter tank (Φ1200×2800mm) of the catalytic reactor made of stainless steel, two porous partitions are placed in parallel, and the filling accounts for 35% of the volume of the catalytic reactor. Manganese sand catalyst, at a reaction temperature of 45°C, a catalytic reaction pressure of 0.3mPa, an oxidation reaction time of 3 minutes, a silver-loaded activated carbon deoxidation catalytic reaction temperature of 250°C, a desorption deaerator inlet water pump pressure of 3mPa, and a deoxygenated water reflux of 50% Under the conditions of UV and UV sterilization, the water quality of raw water after precipitation treatment is 11.2 mg / l of petroleum, 7.1 mg / l of volatile phenol, 8.4 mg / l of sulfide, 10.7 mg / l of SS and 10.7 mg / l of Fe 2+ 3.9mg / l, the reaction treatment was carried out under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com