Method for preparing z-deoxy-D-glucose

A technology of glucose and dideoxy, applied in the direction of deoxy/unsaturated sugar, etc., can solve the problems of low selectivity and low yield, and achieve the effects of good selectivity, good production safety and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

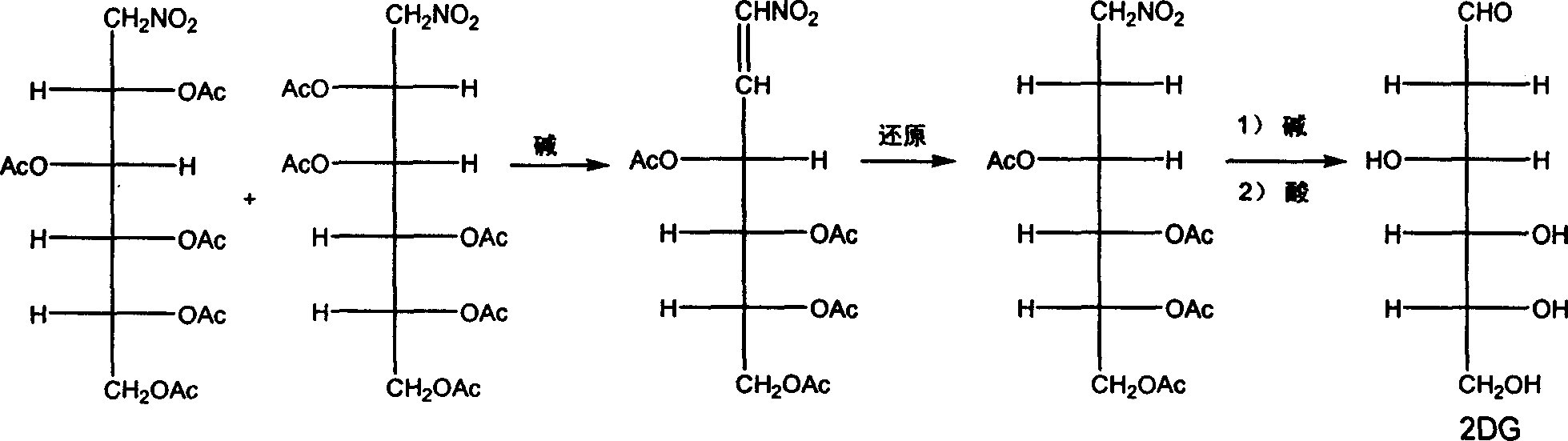

Method used

Image

Examples

Embodiment 1

[0028] 1), the preparation of D-arabo-tetraacetyl-1-nitrohexene-1:

[0029] In 50 ml of n-hexane, add 3.53 grams of 1-nitro-1-deoxy-D-mannose pentaacetate, 3.8 grams of sodium bicarbonate, and react at 60°C; after the reaction is completed, cool, filter, and spin the filtrate under reduced pressure The solvent was removed by evaporation, and the residue was recrystallized from 20-40 ml of ethyl acetate to obtain 2.69 g of a white flaky solid, namely D-arabo-tetraacetyl-1-nitrohexene-1, with a yield of 89.1%.

[0030] 2), the preparation of 1-nitro-1,2-dideoxy-D-arabo-hexose tetraacetate:

[0031] Add 1.85 g of D-arabo-tetraacetyl-1-nitrohexene-1 to 25 ml of solvent (methanol:ether volume ratio 1:1), add 0.15 g of lithium borohydride and 0.50 g of aluminum oxide as an additive; Stir the reaction at 30°C until the raw material disappears, filter, and neutralize the filtrate to PH6-8 with 5% hydrochloric acid by weight, remove the solvent by rotary evaporation under reduced pres...

Embodiment 2

[0036] 1), the preparation of D-arabo-tetraacetyl-1-nitrohexene-1:

[0037] In 50 ml of cyclohexane, add 3.53 grams of 1-nitro-1-deoxy-D-mannose pentaacetate, 4.0 grams of sodium carbonate, and react at 50 ° C; after the reaction is completed, cool, filter, and spin the filtrate under reduced pressure The solvent was removed by evaporation, and the residue was recrystallized through 20-40 ml of ether to obtain 2.52 g of a white flaky solid, ie, D-arabo-tetraacetyl-1-nitrohexene-1, with a yield of 83.4%.

[0038] 2), the preparation of 1-nitro-1,2-dideoxy-D-arabo-hexose tetraacetate:

[0039] Add 1.85 g of D-arabo-tetraacetyl-1-nitrohexene-1 to 30 ml of solvent (methanol:chloroform volume ratio 1:1), add 0.20 g of potassium borohydride, and stir the reaction at 50°C until the raw material disappears , with a weight concentration of 5% hydrochloric acid to neutralize to PH6-8, remove the solvent by rotary evaporation under reduced pressure, add 30 ml of water, extract with chlo...

Embodiment 3

[0044] 1), the preparation of D-arabo-tetraacetyl-1-nitrohexene-1:

[0045] In 50 ml of toluene, add 3.53 grams of 1-nitro-1-deoxy-D-mannose pentaacetate, 4.8 grams of potassium carbonate, and react at 80°C; after the reaction is completed, cool, filter, and remove the filtrate by rotary evaporation under reduced pressure solvent, the residue was recrystallized from 20-40 ml of ethyl acetate-petroleum ether (10 ml of ethyl acetate), and 2.67 g of white flaky solids were obtained, that is, D-arabo-tetraacetyl-1-nitrohexene- 1. The yield is 88.4%.

[0046] 2), the preparation of 1-nitro-1,2-dideoxy-D-arabo-hexose tetraacetate:

[0047] Add 1.85 g of D-arabo-tetraacetyl-1-nitrohexene-1 to 30 ml of solvent (methanol: tetrahydrofuran volume ratio 1:5), add 0.12 g of sodium borohydride, and stir the reaction under reflux until the raw materials disappear. Neutralize to PH6-8 with 5% hydrochloric acid by weight, remove the solvent by rotary evaporation under reduced pressure, add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com