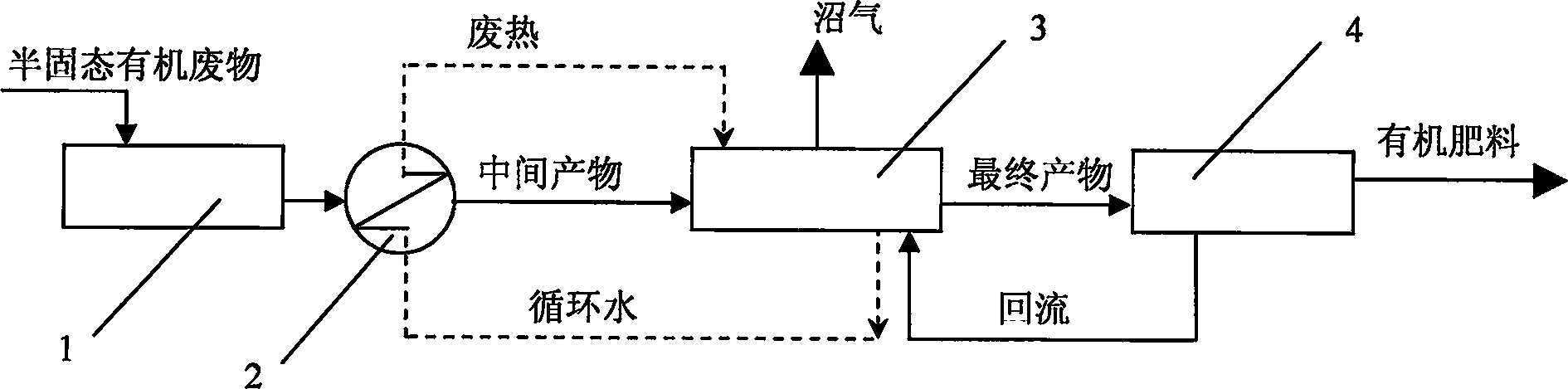

Technique of producing fertilizer, producing gas by digesting organic waste in semi-solid state in two phases

An organic waste, semi-solid technology, applied in the directions of organic fertilizer, organic fertilizer preparation, waste fuel, etc., can solve the problems of low value of the final product fertilizer, incomplete killing of pathogenic bacteria, and inability to recover energy, etc., and achieve a simple structure. , a wide range of applications, to achieve the effect of zero emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] Firstly, the semi-solid organic waste enters the high-temperature micro-aerobic digestion unit 1 in the first stage after preliminary cleaning of coarse debris, and supplies oxygen to the high-temperature micro-aerobic digestion unit 1 to maintain the dissolved oxygen concentration of the semi-solid waste in the unit. 0.1~0.8mg / L. In the micro-aerobic state, many aerobic and facultative microorganisms can digest and degrade organic waste, while consuming oxygen and releasing heat, so as to realize the spontaneous temperature rise of high-temperature micro-aerobic digestion unit 1, and the volatility in semi-solid organic waste When the solid concentration is above 3%, the temperature of the digestive liquid in the high-temperature micro-aerobic digestion unit 1 can reach above 55°C, maintain the temperature of the digestive liquid at 55°C-70°C, and keep it for 1-3 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com