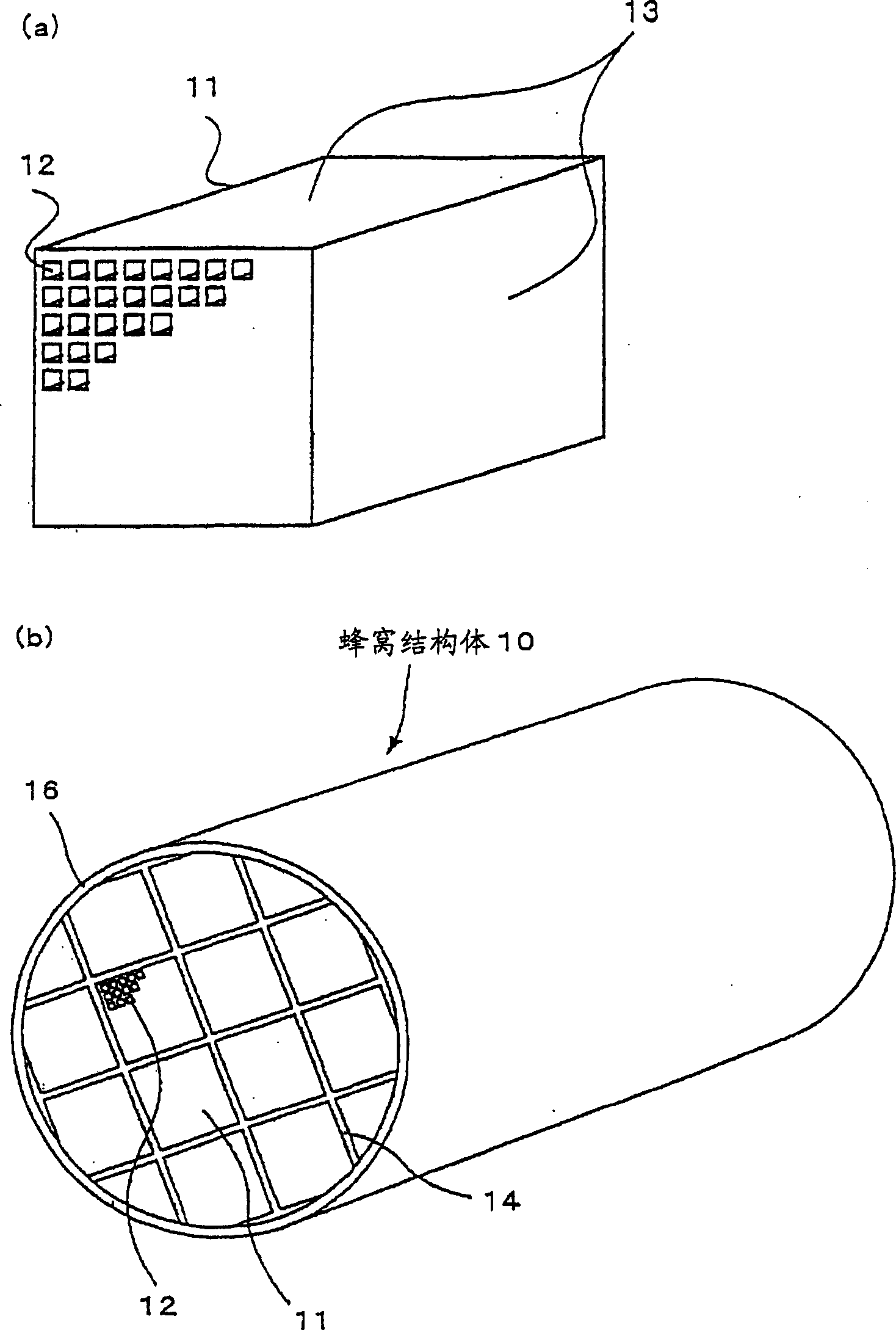

Honeycomb structure

A honeycomb structure, honeycomb technology, used in gas treatment, household appliances, engine components, etc., can solve the problems of reduced specific surface area, large thermal stress, uneven heating of exhaust gas, etc., to achieve excellent durability and strong resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] (1) 40% by weight of γ-alumina particles (average particle size of 2μm) and 10% by weight of silica-alumina fibers (average fiber diameter of 10μm, average fiber length of 100μm, and aspect ratio of 10) , 50% by weight of silica sol (solid concentration of 30% by weight) is mixed to obtain a mixture. With respect to 100 parts by weight of the obtained mixture, 6 parts by weight of methyl cellulose as an organic binder is added, and a small amount of plasticizer and lubricant are added, and further mixing and kneading are performed to obtain a mixed composition. Next, the mixed composition is extruded and molded by an extrusion molding machine to obtain a green body.

[0157] (2) Next, using a microwave dryer and a hot-air dryer, the above-mentioned formed body is sufficiently dried, and further, it is kept at 400° C. for 2 hours for degreasing.

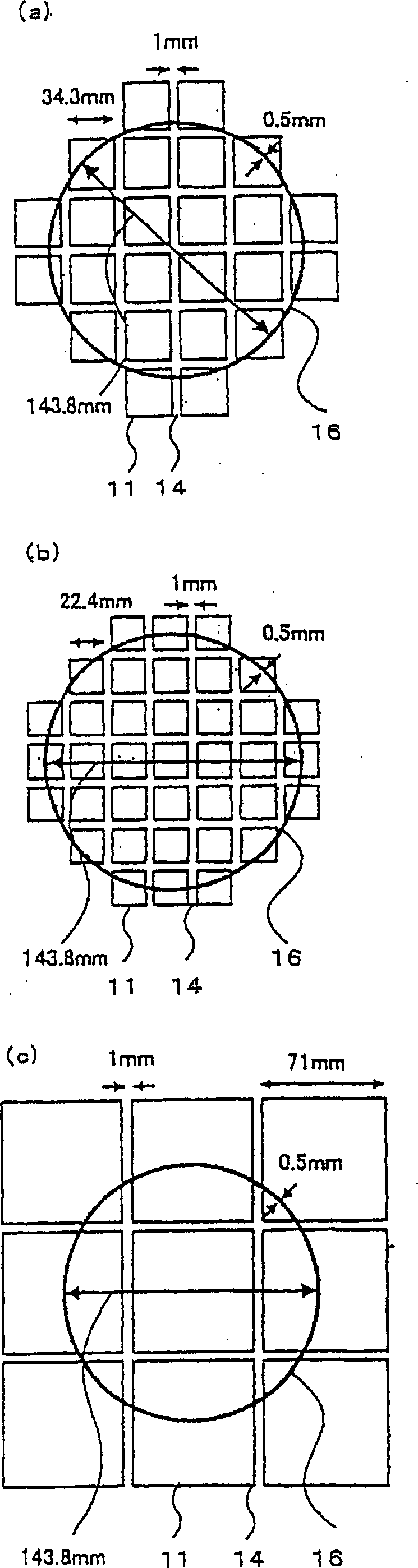

[0158] Then, it was kept at 800°C for 2 hours and fired to obtain a square column shape (34.3mm×34.3mm×150mm) with a cell density...

Embodiment 2、3

[0171] Except having made the honeycomb unit into the shape shown in Table 2, it carried out similarly to Example 1, and manufactured the honeycomb structure.

[0172] Moreover, for the ceramic components involved in Examples 2 and 3, the schematic diagrams viewed from the front are as follows: image 3 (b), image 3 (c) Shown.

Embodiment 4

[0174] Except having used the above-mentioned paste B as the sealing material paste and the coating material paste, respectively, it carried out similarly to Example 1, and manufactured the honeycomb structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com