Copper phthalocyanine liquid solid phase mixed type continuous reactor and its process

A technology of copper phthalocyanine and reactor, which is applied in the field of copper phthalocyanine liquid-solid phase mixed continuous reactor and its technology, can solve the problems of long process cycle, poor reaction efficiency, a large number of equipment, etc., and achieve fast mass transfer and time-saving Long, solvent-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

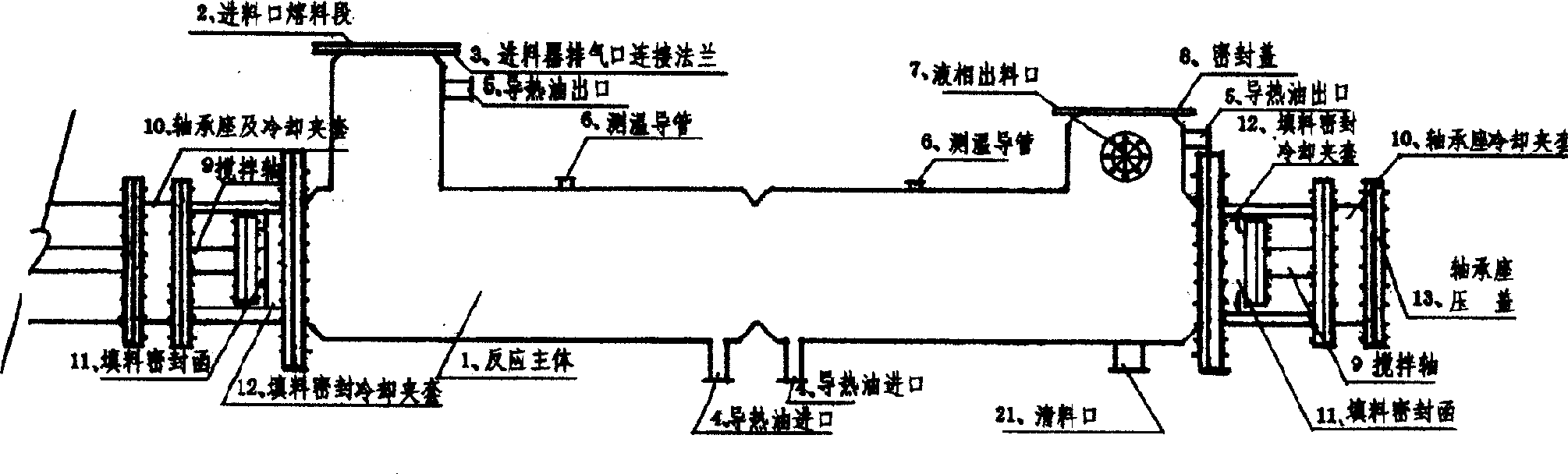

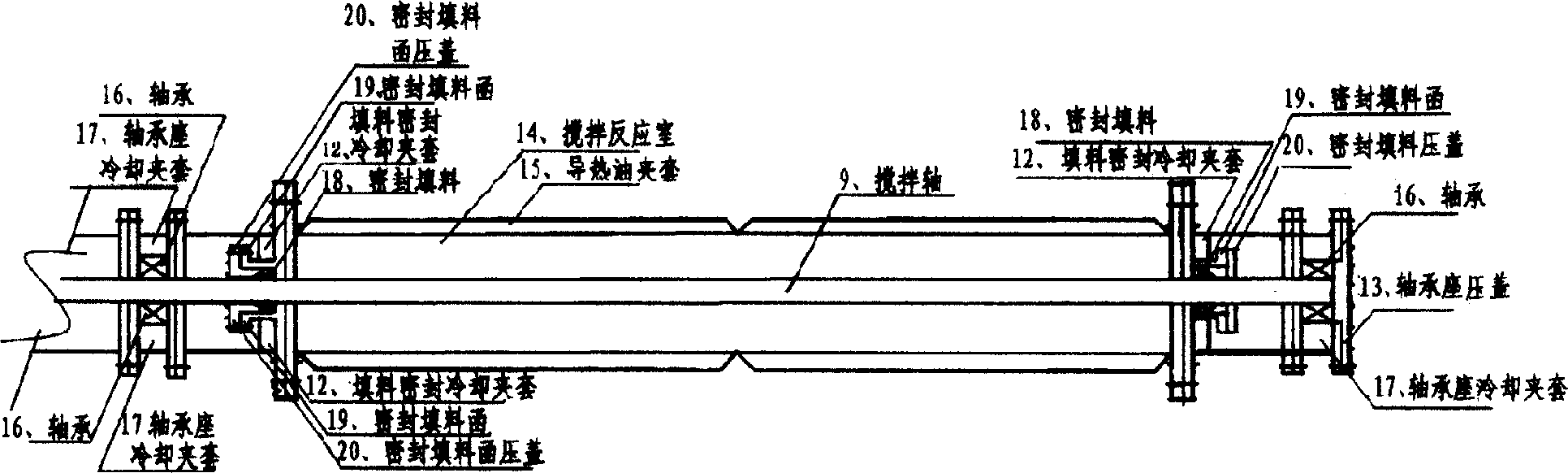

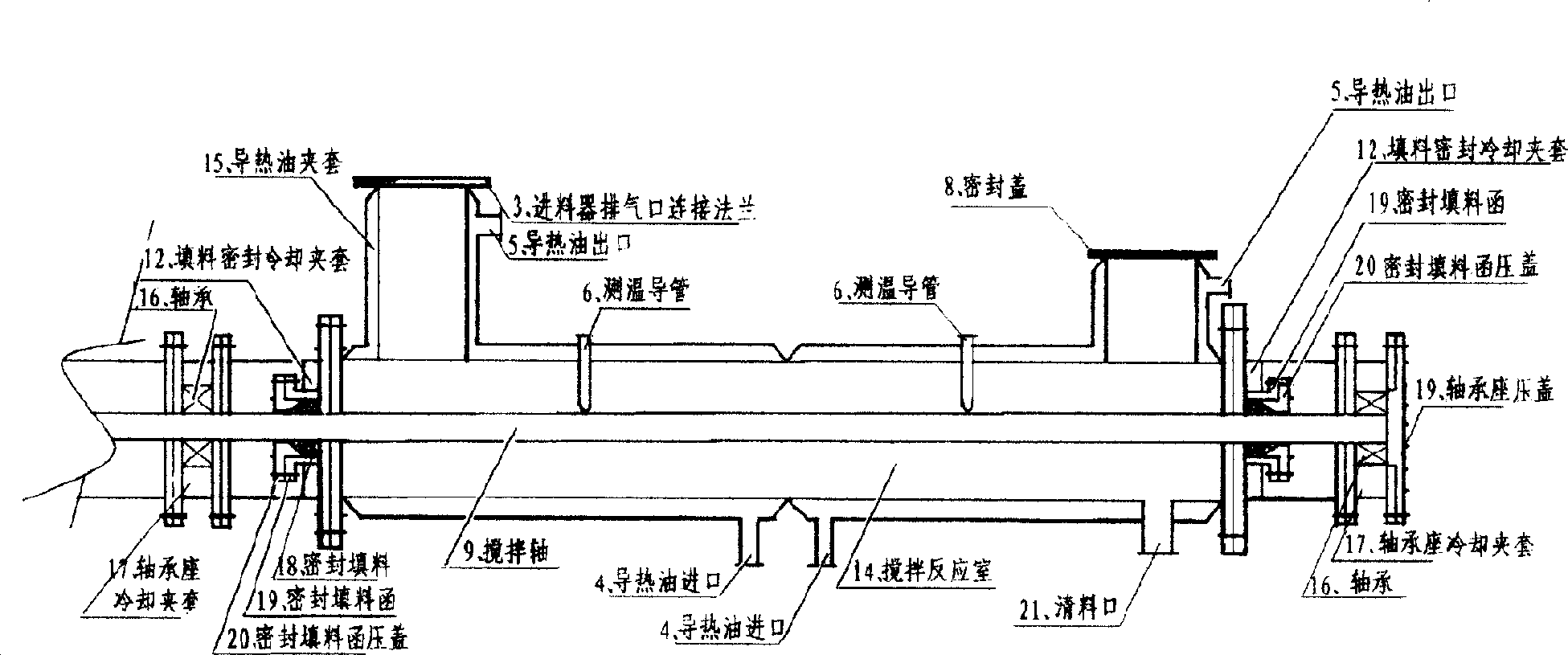

[0015] exist figure 1 The medium material enters the melting section (2) of the feed inlet through the automatic feeder, enters the reactor main body (1) in a molten state, and stirs and reacts at a temperature of 160°C-170°C. The temperature is controlled by the temperature measuring tube (6) The temperature measuring coupler transmits the temperature information to the automatic thermostat through the wire, and the automatic thermostat controls the solenoid valve to supply or cut off the supply through the heat transfer oil inlet (4) according to the set temperature parameters to control the temperature required for the reaction. In the main body of the reactor (1), the molten reaction material is stirred by the stirring shaft (9), which makes the heat transfer and mass transfer more uniform, so that the reaction can proceed smoothly in the main body of the reactor (1). , after two hours of reaction in the reactor main body (1), the reaction material is light green molten at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com