Polyurethane modified gamma-aminopropyl-triethoxy-silane precursor and its hydrolyte

A technology of aminopropyltriethoxysilane and polyurethane modification, which is applied in textiles, papermaking, fiber treatment, etc. It can solve the problems of high baking temperature and yellowing of fabrics, and achieve lower baking temperature and better washability. and anti-felting performance improvement, excellent washing anti-felting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation of PPT (molecular weight 3500) reacts with IPDI to generate prepolymer.

[0040] At room temperature, 66.9 grams of PPT was added to a four-necked bottle, the temperature was raised to 120°C, nitrogen was passed under a pressure of 600mmHg, and the PPT was evacuated for 1.5 hours to purify the PPT; PPT : n IPDI =1: 3-4) the calculated IPDI quality is 13.38 grams, dropwise joins in the four-necked bottle, and passes N 2 protection, the temperature was raised to 100° C., 0.02 g of DBTDL was added, the reaction was continued for 1 hour, and the reaction temperature was lowered to room temperature to obtain a prepolymer.

Embodiment 2

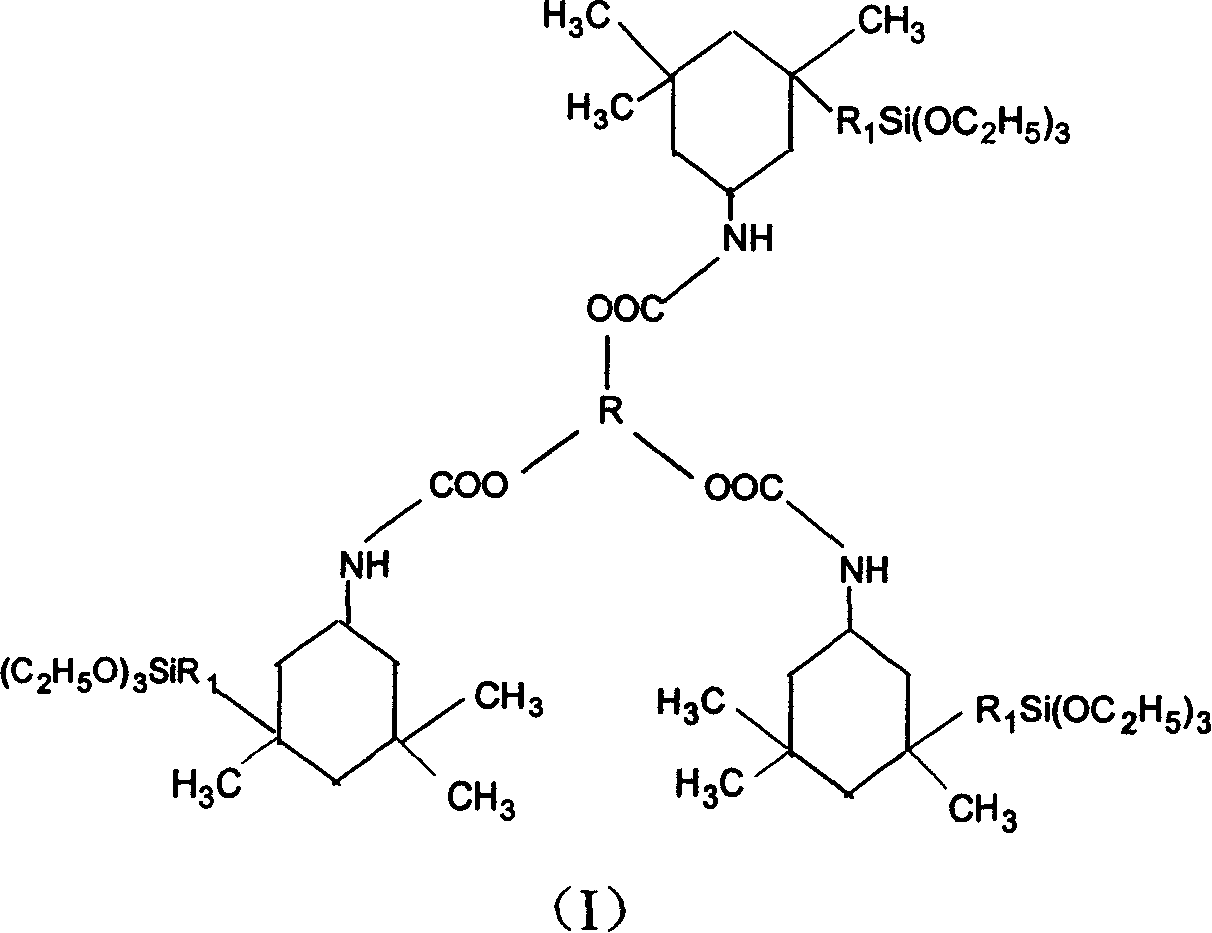

[0042] Preparation of Polyurethane Modified γ-Aminopropyltriethoxysilane Precursor.

[0043] At normal temperature, the ethanol of 20.7 grams is joined in the prepolymer of embodiment 1, according to measuring the content (di-n-butylamine-hydrochloric acid titration method) of free isocyanate group in the prepolymer, according to n NCO : n γ-氨丙基三乙氧基硅烷 =1:1-2, after calculating the required mass of γ-aminopropyltriethoxysilane to be 10.28 grams, add it dropwise into the reaction system, after the dropwise addition, raise the temperature to 80°C, and react for 120 minutes, The reactant becomes clear, and the temperature is lowered to room temperature to obtain a polyurethane-modified γ-aminopropyltriethoxysilane precursor.

Embodiment 3

[0045] Preparation of Polyurethane Modified γ-Aminopropyltriethoxysilane Hydrolyzate

[0046] Add 78.9 grams of the polyurethane-modified γ-aminopropyltriethoxysilane precursor of Example 2 into a three-necked bottle, slowly add a blended solution of 252.48 grams of ethanol and 63.12 grams of water under constant stirring at room temperature, and then add acetic acid Adjust the pH to 5-6, vigorously stir for 5 hours, and then stand still for 10 hours to obtain a transparent and stable polyurethane-modified γ-aminopropyltriethoxysilane hydrolyzate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com