Treating, recovering and reutilizing method for electroplating waste liquid containing heavy metals

A technology for electroplating waste liquid and heavy metals, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

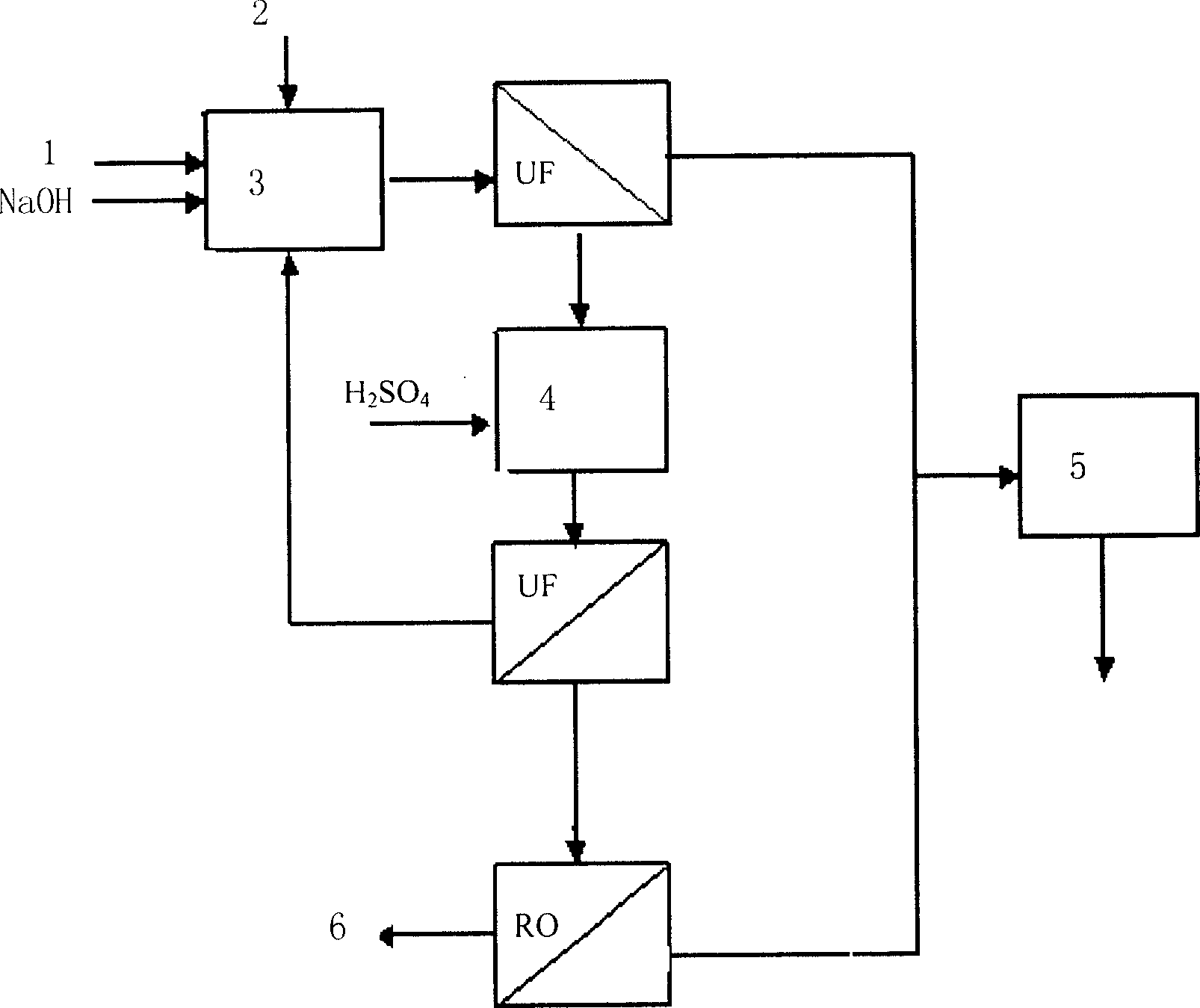

Method used

Image

Examples

Embodiment 1

[0020] 1) Complexation: Take 1L of copper electroplating solution with a copper concentration of 60mg / L, add 1L of complexing agent with a concentration of 1.7g / L and 0.1L of NaOH solution with a concentration of 1g / L, and adjust the pH to 6-7 under stirring , stirring time 20min.

[0021] 2) Ultrafiltration: pump the copper-containing complex solution into the ultrafiltration equipment for ultrafiltration concentration, remove a large amount of impurities such as water and small molecules, and obtain 1L of ultrafiltrate to enter the next process. The selected ultrafiltration membrane is a polyvinylidene fluoride membrane with a molecular weight cut-off of 50,000 (such as flat membranes such as UF605-2 and UF610 in the United States). The ultrafiltration process conditions are: room temperature, inlet pressure 3Bar, outlet pressure 1Bar, and concentration times 2 times. Under the experimental conditions, copper can be removed by 98.1% during the complex ultrafiltration process...

Embodiment 2

[0026] 1) Complexation: Add 1L of complexing agent with a concentration of 1.8g / L and 0.1L of NaOH with a concentration of 1g / L to 1L of chromium electroplating solution with a chromium ion concentration of 200mg / L, and adjust the pH to 6~ 7. Stirring time is 20min.

[0027] 2) Ultrafiltration: Pump the chromium-containing complex solution into the ultrafiltration equipment for ultrafiltration concentration, remove a large amount of impurities such as water and small molecules, and the ultrafiltrate enters the next process. The selected ultrafiltration membrane is a polyvinylidene fluoride membrane with a molecular weight cut-off of 50,000 (such as flat membranes such as UF605-2 and UF610 in the United States). The ultrafiltration process conditions are: room temperature, inlet pressure 3Bar, outlet pressure 1Bar, concentration factor 1.8 times, under the test conditions, 98.3% of chromium can be removed in the process of complex ultrafiltration, and the concentration of chrom...

Embodiment 3

[0032] 1) Complexation: Add 1L of complexing agent with a concentration of 1.9g / L and 0.1L of NaOH with a concentration of 1g / L to 1L of nickel electroplating solution with a nickel concentration of 220mg / L, and adjust the pH to 6-7 while stirring. 20min.

[0033] 2) Ultrafiltration: Pump the nickel-containing complex solution into the ultrafiltration equipment for ultrafiltration concentration, remove a large amount of impurities such as water and small molecules, and the ultrafiltrate enters the next process. The selected ultrafiltration membrane is a polyvinylidene fluoride membrane with a molecular weight cut-off of 50,000 (such as flat membranes such as UF605-2 and UF610 in the United States). The ultrafiltration process conditions are: room temperature, inlet pressure 3Bar, outlet pressure 1Bar, concentration factor 2.1 times, under the test conditions, nickel can be removed by 98.3% during the complex ultrafiltration process, and the nickel concentration in the permeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com