Method for producing heavy blended gallium nitride field effect transistor

A gallium nitride field and heavy doping technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the doping amount cannot be increased, the output power cannot be increased, and the performance cannot be improved. Current collapse, increase output power, reduce the effect of current collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific manufacture example 1

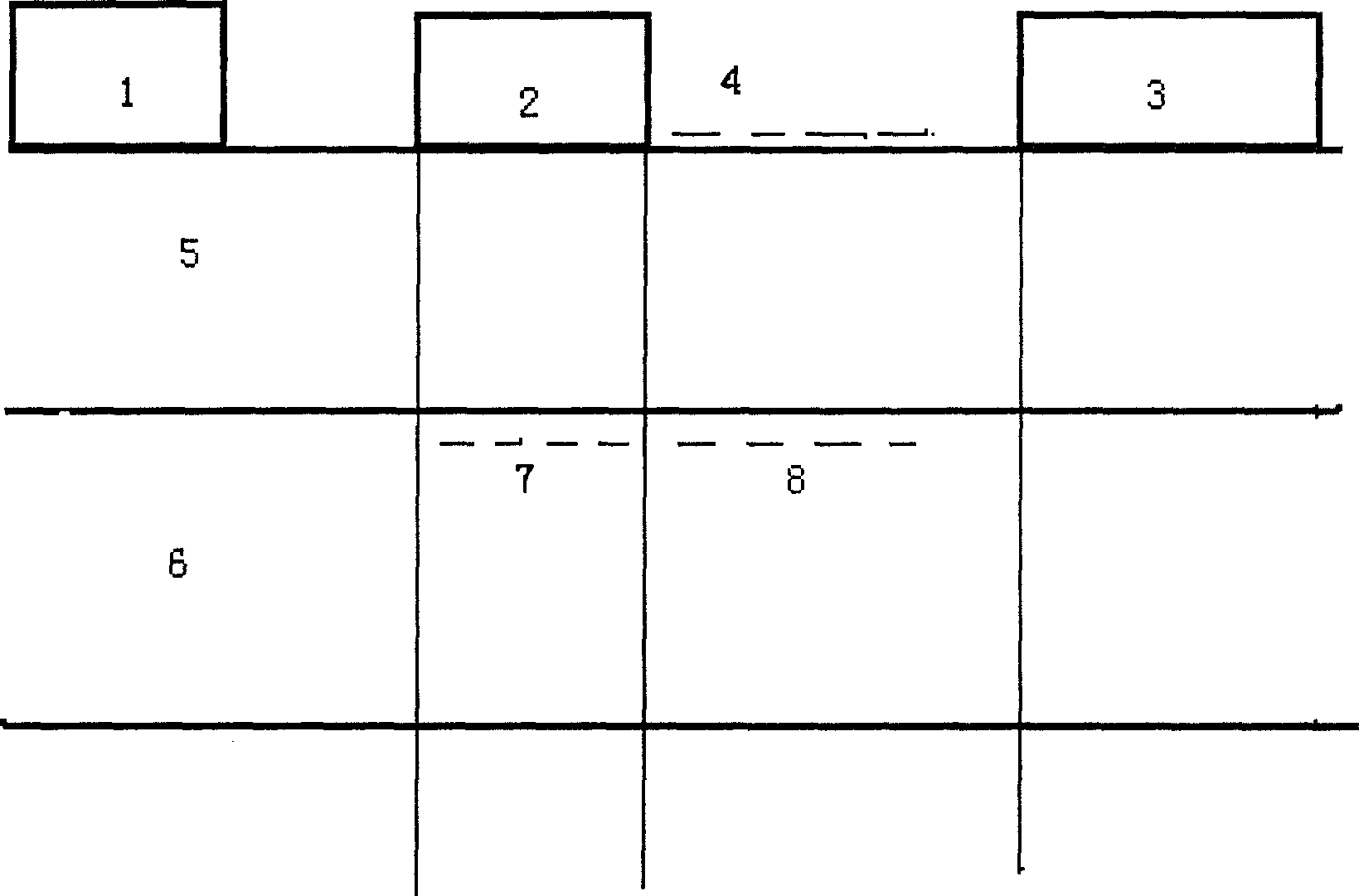

[0031] Specific manufacturing example 1: Take the thickness d of the cap layer 7 =2nm, doped layer thickness d 6 =20nm, the doping concentration is 10 19 cm -3 , isolation layer thickness d 5 =1nm, the Al composition ratio of the barrier layer is 0.3. Self-consistently solving the Schrödinger equation and Poisson equation, the electron gas density when the barrier layer is doped and undoped is 2.27*10 respectively 13 / cm 2 and 1.24*10 13 / cm 2 . The pinch-off voltages calculated by formula (2) are -10.1V and -5.5V, respectively. When there is no doping, the pinch-off voltage just meets the above nW rule, and the channel can be pinched off normally. For the doping barrier, use fluorine plasma treatment (control the plasma emission power between 100-150W, and the treatment time is between 120-180 seconds) to increase the inner channel barrier by 5V, then the pinch-off of the inner channel The voltage is -5.1V. It also meets the nW rule and can be pinched off normally....

specific manufacture example 3

[0033] Specific manufacturing example 3: When the Al composition ratio is lower, the electron gas density decreases, and the thickness W of the barrier layer can be appropriately increased to increase the electron gas density. Take the Al composition ratio as 0.2, and the doped layer thickness d 6 =25nm, the doping concentration is 8*10 18 cm -3 . At this time, the electron gas density when the barrier layer is doped and undoped is 1.81*10 13 / cm 2 and 7.88*10 12 / cm 2 . The pinch-off voltages calculated by formula (2) are -9.82V and -4.27V, respectively. The undoped pinch-off voltage of -4.27V also complies with the above nW rule, and the channel can be pinched off normally. After the barrier layer is doped, use fluorine plasma treatment (control the plasma emission power between 100-150W, and the treatment time is between 120-180 seconds) to increase the inner channel barrier by 5V, then the clamping of the inner channel The cut-off voltage is -4.82V. Also within t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com