Manufacturing process of composite abrasion-proof stick

A manufacturing process and process technology, which is applied in the field of manufacturing process of composite wear-resistant rods, can solve the problems of short service life, low impact strength, low hardness, etc., and achieve the effects of stable production quality, high usability and high wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

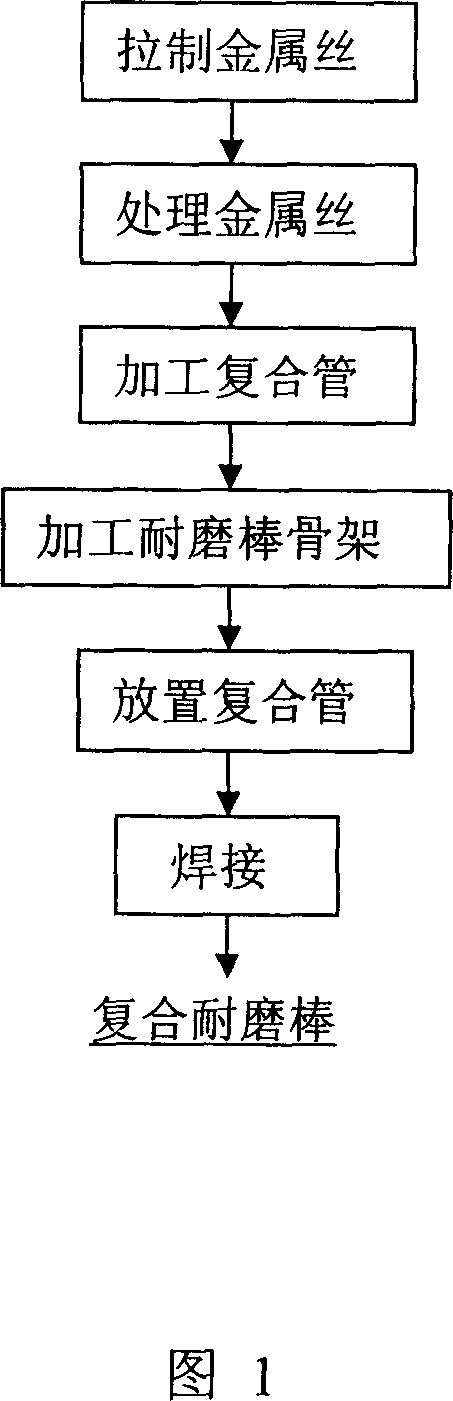

[0026] Process flow of the present invention, see Fig. 1. The manufacturing process steps of composite wear-resistant rods are as follows:

[0027] a. Drawn wire. According to the needs of different working conditions, metal materials with different components are selected, and nano-structured metal wires 1 with a diameter of 0.1-2.5 mm are drawn and processed by wire-drawing equipment; the materials of nano-structured metal wires are selected from low-carbon steel, medium-carbon steel, and high-carbon steel. Metal wires, or low-, medium-, and high-carbon alloy steel wires, or metal wires of manganese steel metastable materials, can also be selected from corresponding wire materials.

[0028] b. Handle wire. The nanostructure metal wire 1 is treated with pickling or acetone washing to remove rust, dirt and oil on the surface.

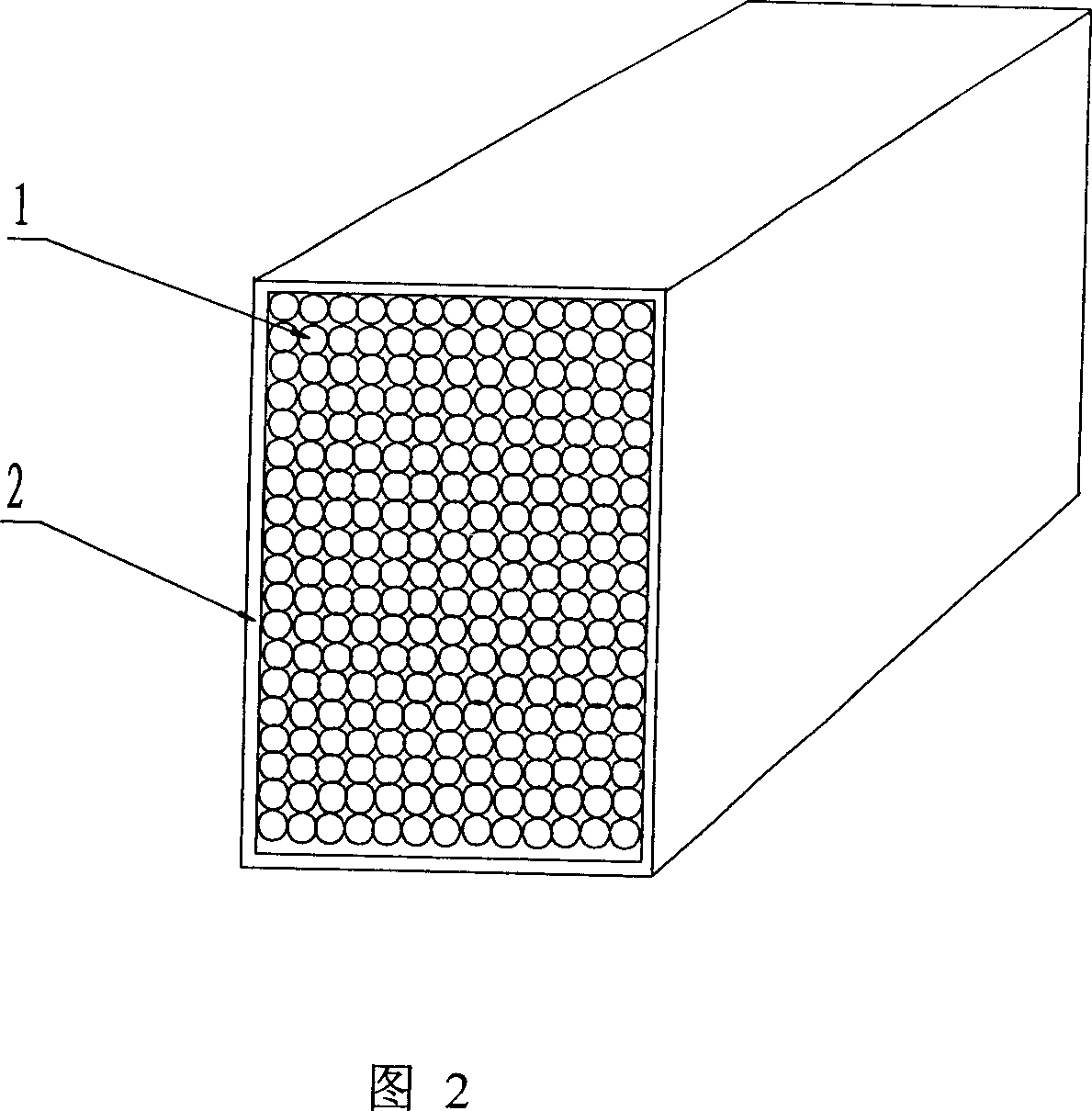

[0029] c. Processing composite pipe. Referring to Fig. 2, according to the specification and size of the wear-resistant rod, determine the size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com