Preparation method of biodegradation polylactic acid based multicomponent block polymer

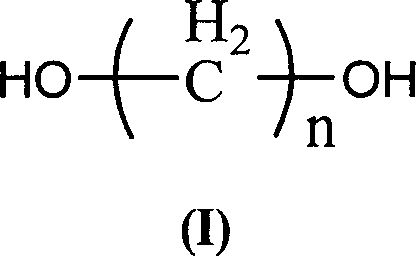

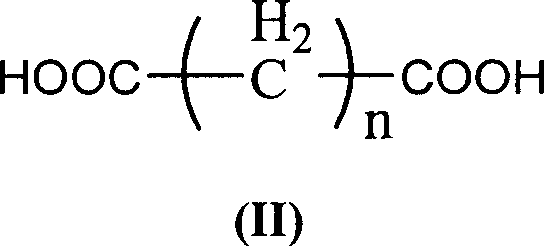

A block polymer, polylactic acid-based technology, which is applied in the field of preparation of biodegradable polylactic acid-based multi-block polymers, can solve problems such as no diols involved, achieve fast degradation speed, easy industrialized integrated production, simple conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Put 800g of L-lactic acid purified by vacuum distillation into a vacuum reactor, add 0.8g of stannous chloride, vacuumize, control the pressure of the reactor at 1.0kPa, raise the temperature of the reactor to 100°C, and react for 5 hours ; Then the temperature of the reactor rose to 140°C, the pressure dropped below 60Pa, and the reaction was continued for 15 hours to obtain the weight average molecular weight M W =2×10 4 -5×10 4 lactic acid prepolymer;

[0039] (2) the linear polyester oligomer polybutylene adipate (PBA), the lactic acid prepolymer (PLA) that step (1) obtains, the chain extender hexamethylene diisocyanate (HDI) respectively Add it to the reactor, the molar ratio of PBA to PLA is 1:9, the molar ratio of the sum of PBA and PLA to HDI is 1:1, and fill with N 2 Air, vacuum, after repeated operations several times, the system pressure dropped below 60Pa, and then reacted at 150°C for 10 minutes, N 2 Discharging under air protection, the desired pro...

Embodiment 2

[0041] (1) Add 800 g of D, L-lactic acid purified by vacuum distillation into a vacuum reactor, add 0.4 g of stannous octoate, vacuumize, control the pressure of the reactor at 1.5 kPa, raise the temperature of the reactor to 110 ° C, and react 4 hours; then the temperature of the reactor rose to 160°C, the pressure dropped below 60Pa, and the reaction was continued for 14 hours to obtain the weight average molecular weight M W =2×10 4 -5×10 4 lactic acid prepolymer;

[0042] (2) Lactic acid prepolymer (PLA), linear polyester oligomer polybutylene succinate (PBS), chain extender diphenylmethane diisocyanate (MDI) obtained in step (1) Add to the reaction kettle respectively, the molar ratio of PBS and PLA is 1:1, the molar ratio of the sum of the molar amounts of PBS and PLA to MDI is 1:1.3, and fill with N 2 Gas, vacuum, after repeated operations several times, the system pressure dropped below 60Pa, and then reacted at 180°C for 20 minutes, N 2 Discharging under air prote...

Embodiment 3

[0044] (1) 400g of L-lactic acid purified by vacuum distillation, D, 400g of L-lactic acid are added to a vacuum reactor, 0.8g of germanium chloride is added, vacuumized, the pressure of the reactor is controlled at 2.0KPa, and the temperature of the reactor is raised to 120°C, react for 3 hours; the temperature of the reactor rises to 180°C, the pressure drops below 60Pa, and the reaction continues for 12 hours to obtain the weight average molecular weight M W =2×10 4 -5×10 4 lactic acid prepolymer;

[0045] (2) Lactic acid prepolymer (PLA), linear polyester oligomer polyhexamethylene adipate (PHA) obtained in step (1), chain extender 4,4'-dicyclohexylmethane Add isocyanate (DES) into the reactor respectively, the molar ratio of PHA and PLA is 9:1, the molar ratio of the sum of PHA and PLA to DES is 1:1.5, and fill with N 2 Gas, vacuum, after repeated operations several times, the system pressure dropped below 60Pa, and then reacted at 200°C for 30 minutes, N 2 Dischargin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com