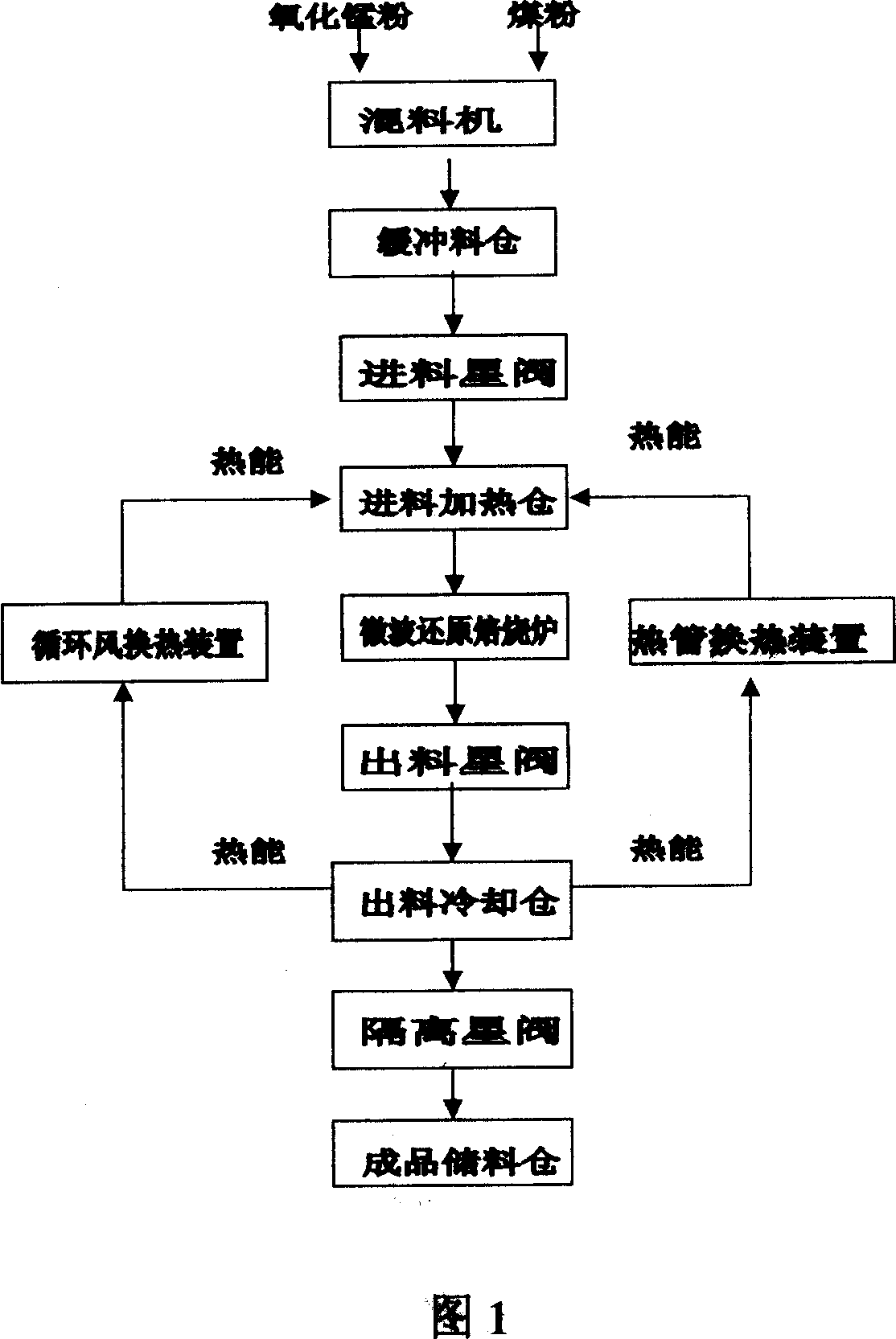

Heat recovering and microwave reducing manganesian ore roasting process and apparatus

A technology of process equipment and roasting process is applied in the field of microwave reduction roasting process and equipment of heat recovery type manganese oxide ore to achieve the effects of large production capacity, reduced energy consumption, and elimination of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

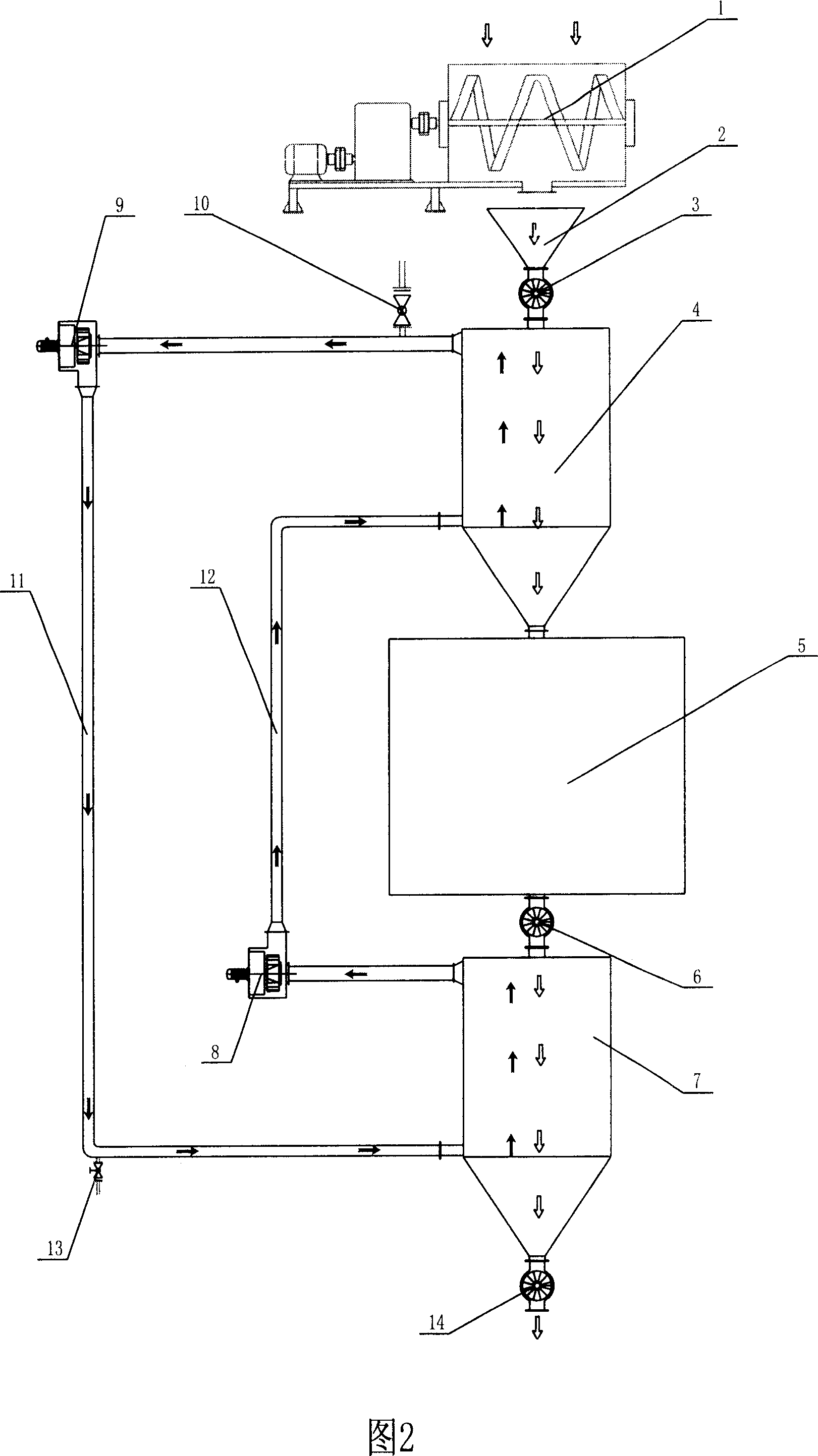

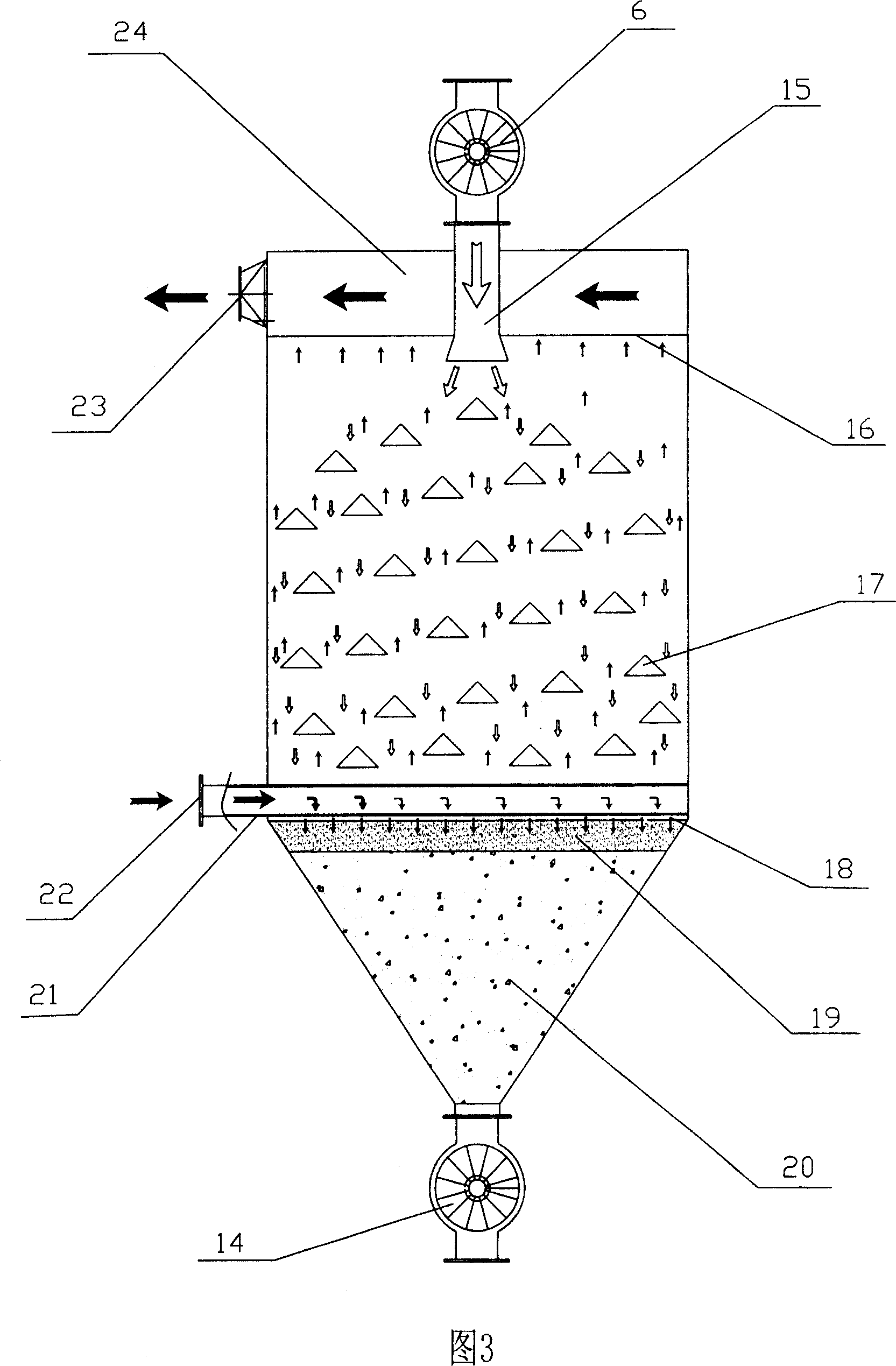

Method used

Image

Examples

Embodiment 1

[0057] 1. Verification experiment

[0058] 1. Purpose of the experiment: To further examine the extent to which microwave equipment can achieve industrial reduction roasting of manganese ore powder, and to explore the reaction conditions and main influencing factors of microwave reduction roasting.

[0059] 2. Experimental equipment and experimental objects

[0060] a. Instruments: industrial microwave roasting furnace for experiment (10kw), precision electronic balance, calculator, hand-held high-precision infrared thermometer (range 0℃~500℃), Prussian brand online high-precision infrared thermometer (range 0℃~900℃), corundum mullite furnace (225mm×145mm×145mm), alumina insulation cotton, sample sealed tank.

[0061] b. Raw materials: Guangxi Daxin Manganese Mine metallurgical slag, Guangxi Daxin Manganese Mine production and use of anthracite powder.

[0062] 3. Roasting reduction process parameters:

[0063] The set experimental conditions are as follows: the roasting te...

Embodiment 2

[0071] The roasting equipment is HWS-18 rotary microwave oven.

[0072] The experimental method is: weighing → mixing → loading and roasting → sampling and forced cooling → sample analysis

[0073] Experimental process: The raw material is divided into 17 samples, each of which is 10 or 20 kg, and the coal mine ratio is 14% or 18%. Under the condition that other process parameters are basically the same, when the microwave heats the material from room temperature to 150°C, it needs to consume about 100 degrees of electricity, and the power consumption in this temperature range accounts for an average of 33% of the total power consumption of roasting; heating to 200°C, 250°C At 300°C, the power consumption of each temperature section accounted for 53%, 68% and 80% of the average value of the total power consumption of roasting respectively. It is generally estimated that using microwaves to roast and reduce manganese ore powder requires approximately 210 to 240 degrees of elec...

Embodiment 3

[0080] for an intermediate test.

[0081] The roasting furnace is a shaft furnace with continuous feeding and discharging. Due to limited conditions, artificial mixing, feeding and star valve mechanical unloading are adopted, without forced water cooling device.

[0082] The hearth of the roasting furnace is 150mm wide and 0.176m in volume 3 . There are 8 groups of microwave generators totaling 189 microwave units. Due to insufficient power supply voltage, only 3 groups of microwave generators can be turned on during the experiment, and the actual power used is 48KW.

[0083] The experimental raw materials are metallurgical manganese powder and anthracite coal powder from Daxin manganese mine.

[0084] experiment procedure:

[0085] Experiment 1: Metallurgical manganese powder 500kg, anthracite coal powder 50kg; after mixing, put it into the roasting furnace for roasting, after the roasting is completed, it is unloaded by the star discharge machine, and the sample is natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com