Spherical cerium-zirconium base composite oxide and its preparing method

A composite oxide, cerium zirconium technology, applied in chemical instruments and methods, separation methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effects of excellent chemical activity, good thermal stability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 36.0g Ce(NO 3 ) 3 ·6H 2 O, 12.0g Zr(NO 3 ) 4 ·5H 2 After O and 100ml of deionized water are heated and dissolved, solution (I) is made after adding 15ml of hydrogen peroxide;

[0036] 15g urea is dissolved in 50ml deionized water to make solution (II);

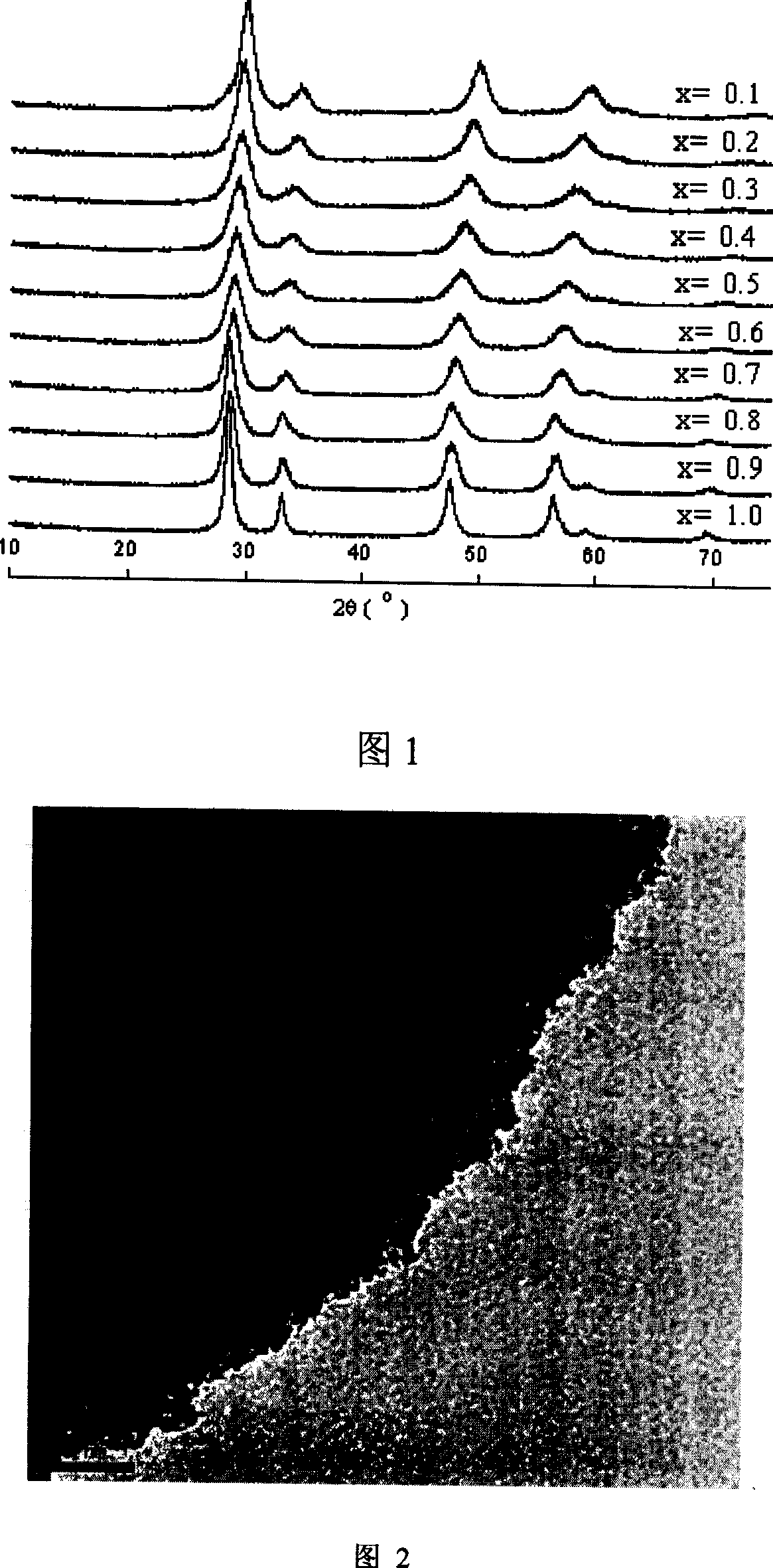

[0037] Add the solution (I) to the solution (II) to the reaction kettle under stirring, heat with an oil bath, keep the temperature at 130°C for 2 hours, cool to 15°C after the reaction, and carry out the precipitation of the formed hydroxide After suction filtration, washed with deionized water and ethanol in sequence, the SEM photo after drying at 110°C for 10 hours is shown in Figure 3, and the surface area after calcination at 550°C for 4 hours is 135m 2 / g, the XRD spectrum is shown in Figure 1; the surface area after calcination at 1000°C for 6 hours is 21m 2 / g, SEM photos are shown in Figure 5.

Embodiment 2

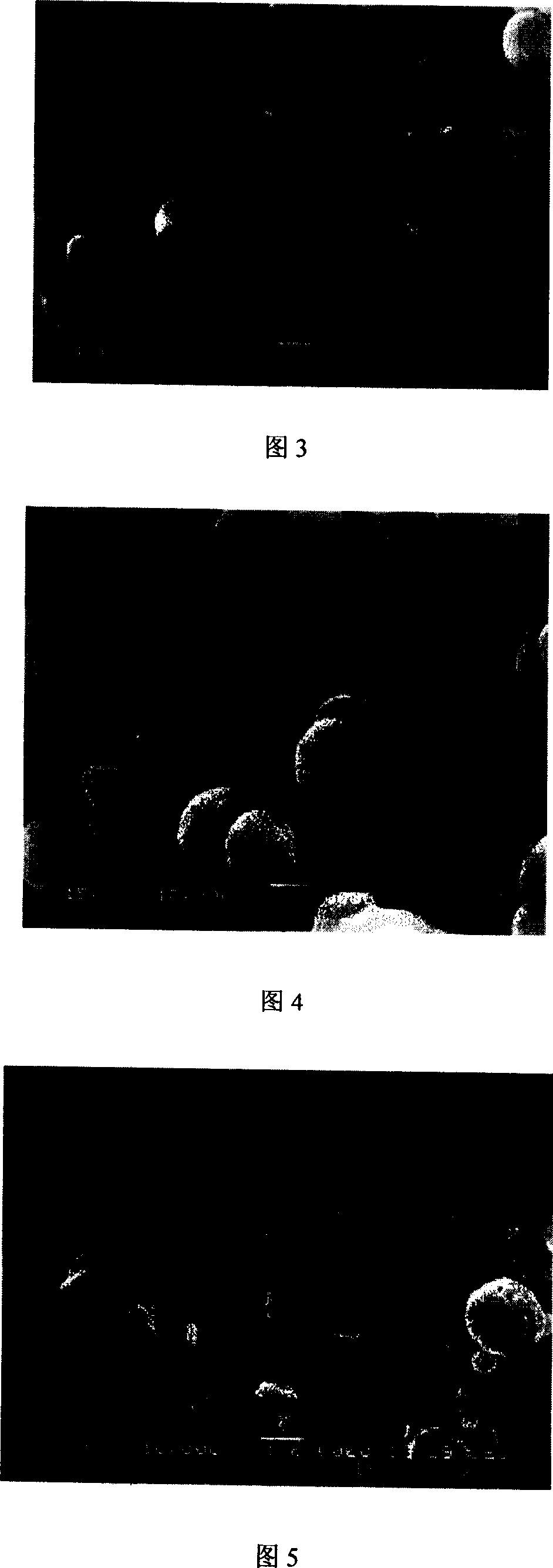

[0039] Take 46.0g (NH 4 ) 2 Ce(NO 3 ) 6 , 12.0g Zr(NO 3 ) 4 ·5H 2 Add O into 150ml of deionized water under stirring, heat to dissolve, add 15g of urea, heat the reactor with an oil bath, keep the temperature at 125°C and keep it for 2h, cool to 30°C after the reaction, and react to the generated hydrogen After the oxide precipitate was suction filtered, washed with deionized water and ethanol respectively, and dried at 110°C for 10 hours, the SEM photo of the dried sample is shown in Figure 3; the surface area after calcination at 550°C for 4 hours was 137m 2 / g, the TEM photo is shown in Figure 2; after calcination at 1000°C for 6 hours, the surface area of the obtained sample is 20m 2 / g.

Embodiment 3

[0041] Take 25.0g Ce(NO 3 ) 3 ·6H 2 O, 26.0g Zr(NO 3 ) 4 ·5H 2 After O and 100ml of deionized water are heated and dissolved, slowly add 15ml of hydrogen peroxide to make solution (I), dissolve 15g of urea in 50ml of deionized water to make solution (II); under stirring, add solution (I) to solution ( II) Put it into the reaction kettle, heat it with an oil bath, keep the temperature at 135°C for 2 hours, cool to room temperature after the reaction, filter the formed hydroxide precipitate, and wash it with deionized water and ethanol respectively , dried at 110°C for 10h, and calcined at 550°C for 4 hours, the surface area is 127m 2 / g, the XRD spectrum is shown in Figure 1; after roasting at 1000°C for 6 hours, the surface area of the obtained sample is 25m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com