The preparation of compound digestive enzyme and its preparation method

A compound digestive enzyme preparation and digestive enzyme technology, which is applied in the field of pharmaceutical dosage forms and preparations, can solve the problems of unevenness, large diameter of multi-enzyme tablets, low enzyme release rate, etc., and achieve the effect of improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

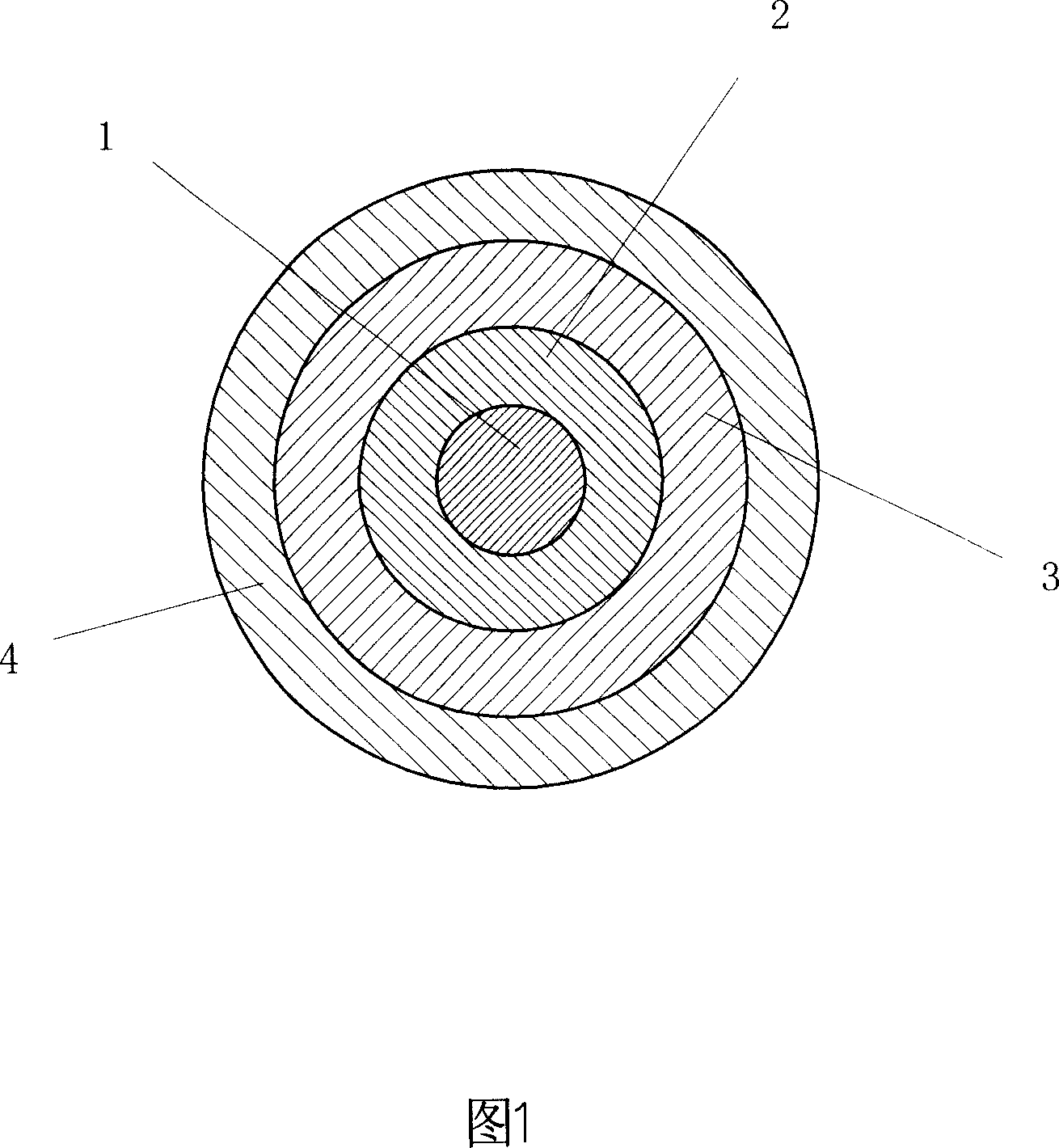

Image

Examples

Embodiment 1

[0015] The composition and ratio of the compound digestive enzyme preparation of this embodiment are shown in Table 1.

[0016] Element

Ratio(%)(w / w)

Enteric-coated digestive enzyme pellet core

64.5

Hydroxypropylmethylcellulose

6.5

Enteric coating layer

Enteric coating material

16.1

Gastric digestive enzyme layer

4.8

1.6

Gastric coating layer

Gastric coating material

6.5

[0017] The preparation steps of the compound digestive enzyme preparation of the present embodiment are as follows:

[0018] ①Put 800g of trypsin powder and 80g of hydroxypropyl methylcellulose into the wet granulator, stir and mix evenly. Add the ethanol solution of 480ml65wt% then, stir and make wet material;

[0019] ②Put the wet material prepared in step ① into an extrusion cutting granulator (the aperture of the screen is 0.3-2.5mm, usually 0.9...

Embodiment 2~ Embodiment 4

[0023] The remainder of embodiment 2~embodiment 4 is identical with embodiment 1, and difference is each constituent and ratio (seeing table 2) of compound digestive enzyme preparation, used adjuvant of preparation process, solvent and their consumption (seeing table 3 ).

[0024] Example 2

[0025] Example 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com