Method for hydrothermally synthesizing series flower shape zinc oxide micron/nano structure

A flower-shaped zinc oxide, nano-structured technology, applied in chemical instruments and methods, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of high cost of molecular beam epitaxy, high temperature requirements, poor controllability, etc. The effect of low, simple method and huge application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

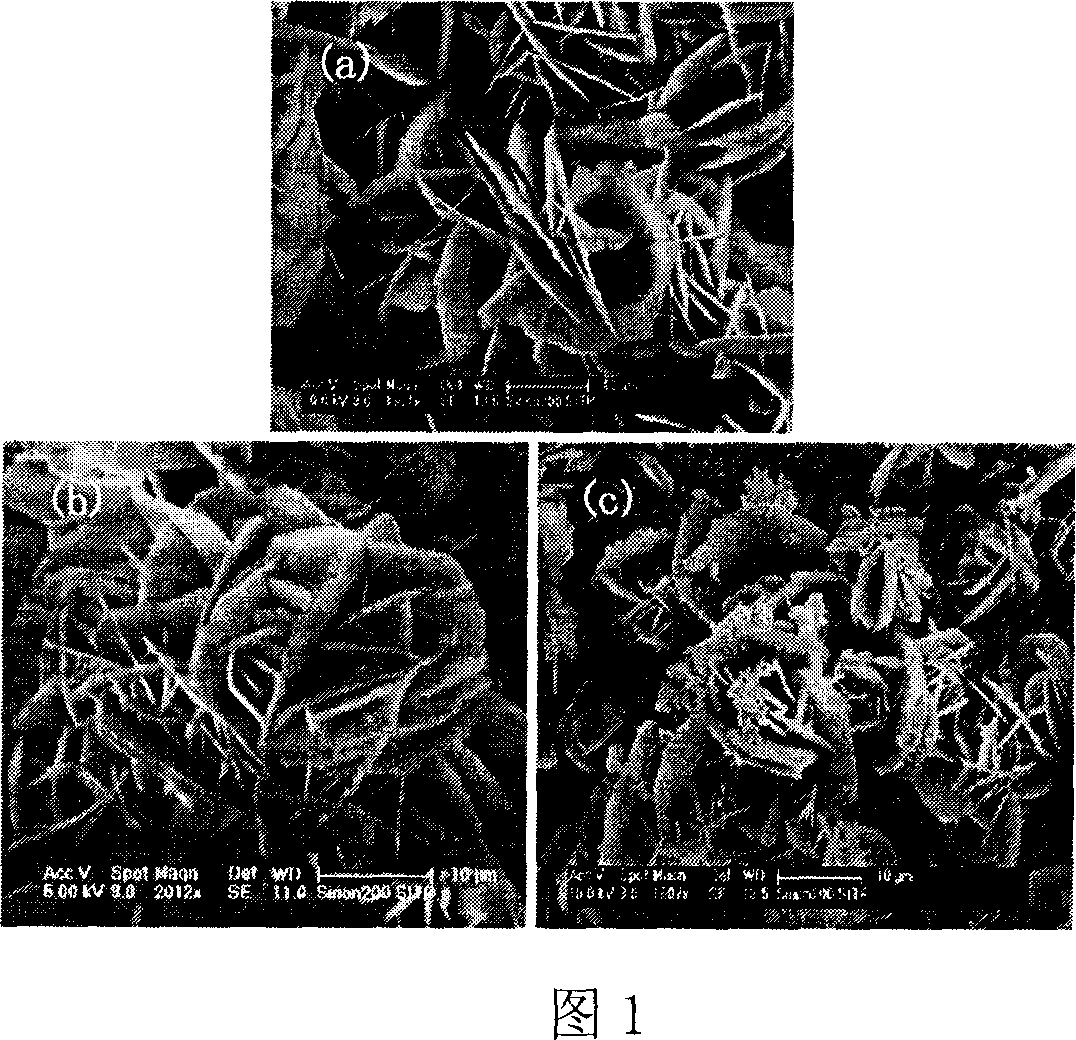

[0018] 1) Drop ammonia water with a mass percentage of 25% into a zinc chloride solution with a concentration of 0.35 mol / l, and adjust the pH values of the solutions to 10.40, 10.80 and 11.15, respectively.

[0019] 2) To clean the substrate, place the copper sheet in a beaker of a mixture of acetone and deionized water or ethanol solution, ultrasonicate for 5 minutes to 1.5 hours, and put it flat into a reaction vessel with a plug.

[0020] 3) Place the prepared solution in a glass vessel with a plug, cover the glass vessel (it is not absolutely sealed, so the air pressure of the solution is almost close to normal pressure), then put it into a drying oven with a temperature of 95 ° C and heat it for 5.5 h, remove the glassware.

[0021] 4) Pour out the reacted transparent liquid and leave a white precipitate, then seal the glassware well, store it at room temperature for 4 hours, take out the sample, wash it with deionized water and dry it naturally. A white thin film was...

Embodiment 2

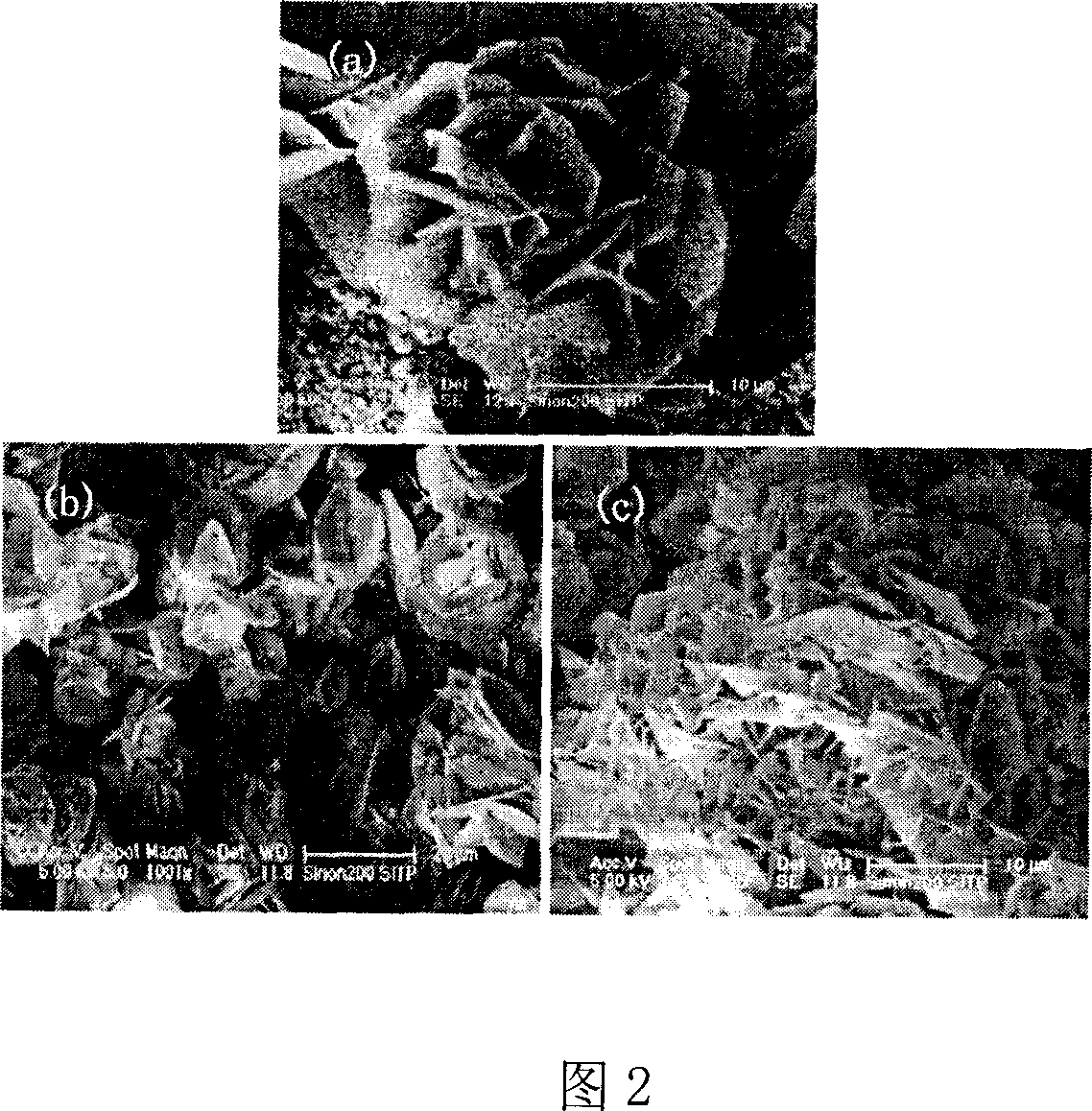

[0024] 1) Drop ammonia water with a mass percentage of 25% into zinc chloride solutions with concentrations of 0.2, 0.35 and 0.45 mol / l respectively, and adjust the pH value of the solution to about 10.60.

[0025] 2) To clean the substrate, place the copper sheet in a beaker of a mixture of acetone and deionized water or ethanol solution, ultrasonicate for 5 minutes to 1.5 hours, and put it flat into a reaction vessel with a plug.

[0026] 3) Put the prepared solution in a glass vessel with a plug, cover the glass vessel (it is not absolutely sealed, so the air pressure of the solution is almost close to normal pressure), then put it into a drying oven with a temperature of 95°C and heat it for 5.5h , remove the glassware.

[0027] 4) Pour out the reacted transparent liquid and leave a white precipitate, then seal the glassware well, store it at room temperature for 4 hours, take out the sample, wash it with deionized water and dry it naturally. A white thin film was deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com