Preparation method and device of acetyl chloride and hydroxy ethylene diphosphonic acid coproduction

A technology for the co-production of acetyl chloride to hydroxyethylene diphosphonic acid and a preparation device, which is applied in the chemical industry and can solve the problems of HEDP production being affected, raffinate cannot be recycled, and accidents are prone to occur, so as to ensure continuous stability and standardization , Realize the effect of standardization and controllability, production safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

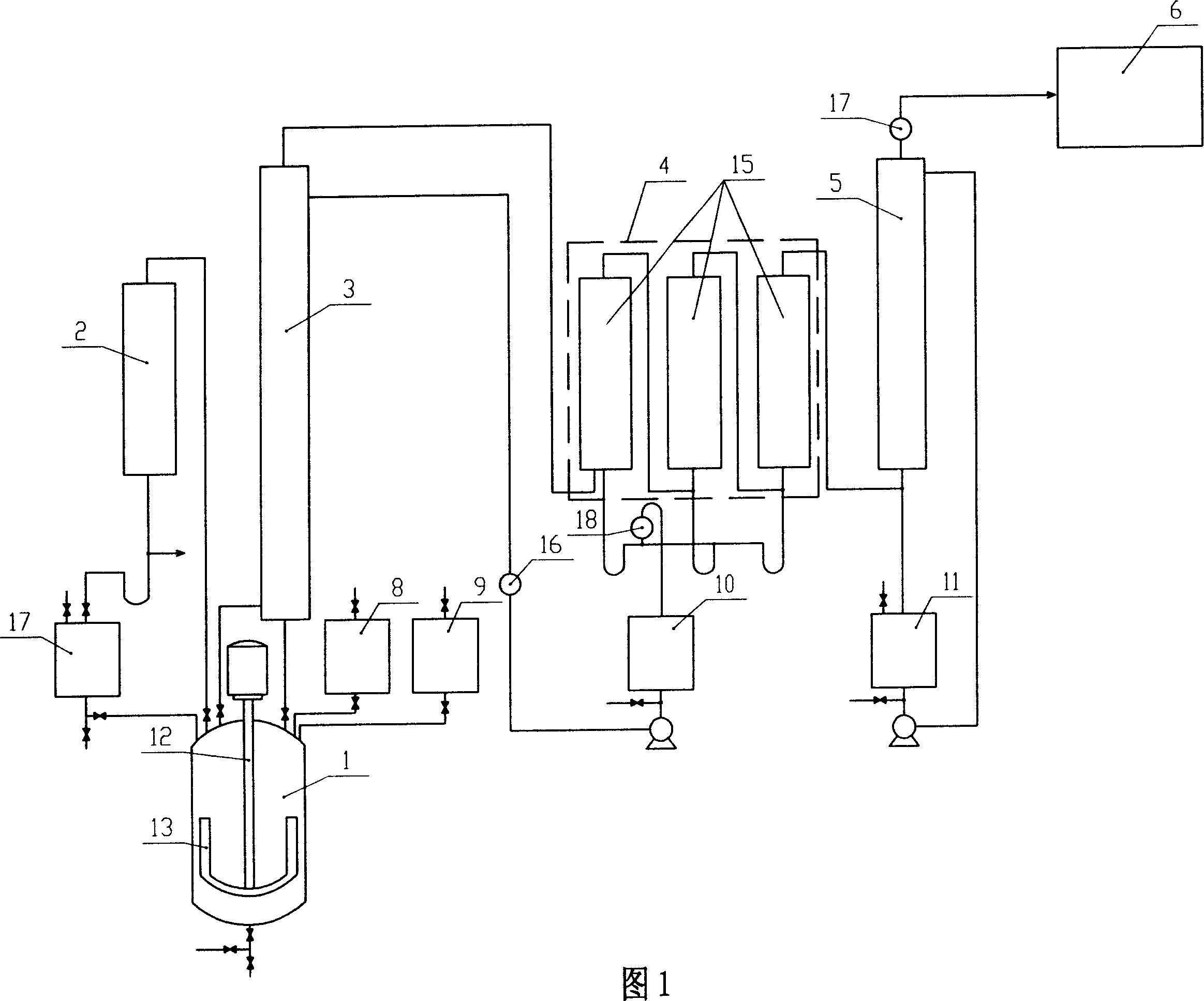

[0051] A kind of preparation method of acetyl chloride coproduction hydroxyethylene diphosphonic acid, it is characterized in that adopting following steps:

[0052] a) After adding glacial acetic acid into the reactor, start stirring, and complete the dropwise addition of phosphorus trichloride to the reactor under normal pressure for 1 to 2 hours, so that the molar number of acetic acid in the reactor is 3.0 to 3.0 to the molar number of phosphorus trichloride. 3.2 times.

[0053] b) Turn on the jacket steam of the reaction kettle, and control the jacket steam flow rate to 30-200kg / h. , so that the reactor can continue to heat up, and through the following three steps:

[0054] Step 1. Directly receive liquid acetyl chloride, and at the same time control the amount of hydrogen chloride gas generated by the reaction in the kettle to be stable at 30-60kg / h, operate for 8-12 hours, and raise the temperature in the kettle to 40-55°C;

[0055] Step 2. Control the reflux rate of...

Embodiment 1

[0065] Add 2190kg of glacial acetic acid into a 3000-liter reactor; start stirring, and dropwise add 1664kg of 98.5% phosphorus trichloride under normal pressure within 1 hour. Kmol. Directly receive the condensed acetyl chloride, the hydrogen chloride gas production is stable at 35-50kg / h, it takes 8 hours, and the temperature in the kettle slowly rises to 46°C; 2.5h, the temperature in the kettle is 54℃, and the temperature at the top of the rectification tower can be stabilized for 0.5h; The temperature began to drop, the reflux of acetyl chloride was stopped, and 1632 kg of 99.21% finished product acetyl chloride was finally received; the temperature in the kettle was 120±2°C, and it took 1.5 hours to keep the hydroxyethylidene diphosphonic acid acetate; the tail gas was used by the absorption tower After absorbing 400kg of glacial acetic acid at 20-30℃, it will be absorbed into 1500kg of 31% hydrochloric acid in the falling film absorber, and finally the weight of the ab...

Embodiment 2

[0067]Add 3360kg of glacial acetic acid into a 5000-liter reactor; start stirring, and dropwise add 2550kg of 98.5% phosphorus trichloride under normal pressure within 1.5 hours. It is 18.29Kmol. Directly receive the condensed acetyl chloride, the hydrogen chloride gas production is stable at 40-55kg / h, it takes 11 hours, and the temperature in the kettle slowly rises to 53°C; 3.5 hours, the temperature in the kettle is 63°C, and the temperature at the top of the rectification tower can be stabilized for 0.5h; The temperature begins to drop, stop the reflux of acetyl chloride, and finally receive 2500 kg of 99.16% finished product acetyl chloride; the temperature in the kettle is 120 ± 2 ° C, and it takes 2 hours to carry out the insulation of hydroxyethylene diphosphonic acid acetate; After absorbing 800kg of glacial acetic acid at ~30°C, it will be absorbed into 2300kg of 31% hydrochloric acid in the falling film absorber, and finally the weight of the absorbed liquid will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com