Method for preparing p type copper sulfide transparent conducting film

A technology of transparent conductive film and copper sulfide, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of low conductivity and transmittance of p-type film, difficult precise control of composition, complicated preparation process, etc. Achieve the effect of smooth and bright surface, low manufacturing cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Using quartz glass as the substrate (glass sheet or glass tube), place the substrate in deionized water, absolute ethanol and acetone solvents for 10 minutes and ultrasonically clean it for 10 minutes to remove the grease and dirt on the surface. Then it was dried in a vacuum oven at 100°C for use.

[0025] (2) Add 0.5 g of 3-amino-propyl-trimethoxysilane dropwise into a mixed solution of 15 ml of absolute ethanol and 5 ml of deionized water, then add 0.05 g of acetic acid, and stir for 15 min. Put the cleaned substrate into the above solution, take it out after standing for 48 hours, wash it with deionized water to remove excess physically adsorbed silane molecules, make the surface of quartz glass self-assemble to form a silane monomolecular film, and dry it in vacuum at 100°C for 30 minutes .

[0026] (3) 0.3157g CuCl 2 2H 2 Dissolve O in 20ml of deionized water, add 1.48ml of triethanolamine, and mix well; then add 2.96ml of NH 4 OH; finally add 50ml of 0.02...

Embodiment 2

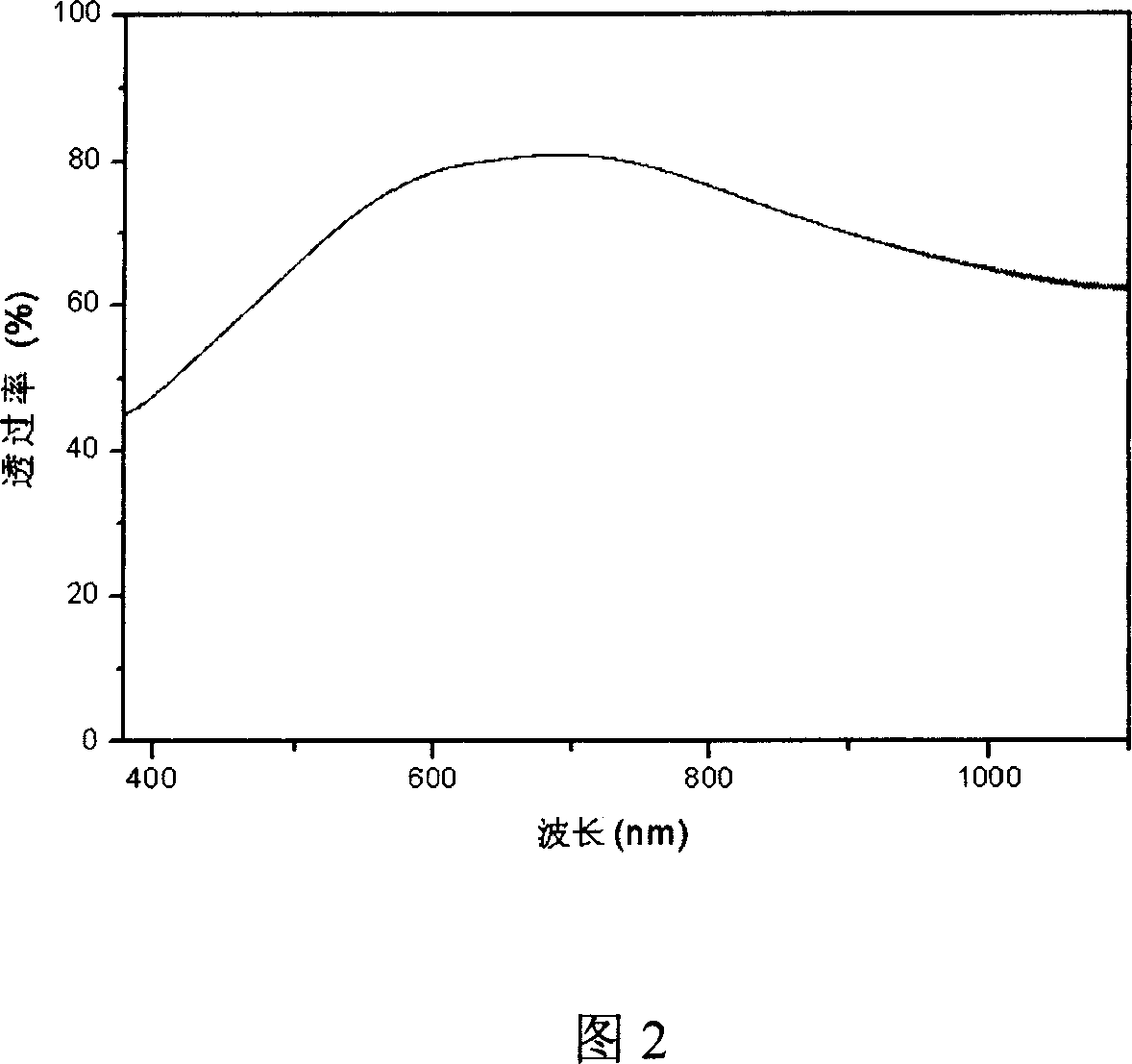

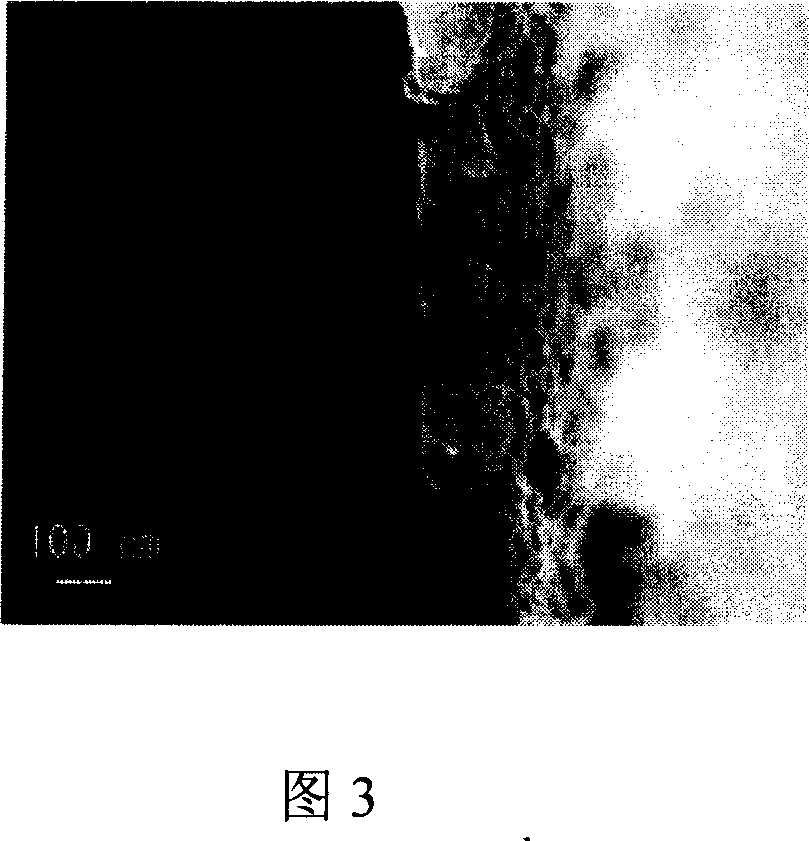

[0030] The cleaning of the quartz glass substrate and the preparation of the monomolecular film are the same as in Example 1. The preparation of the precursor solution adopts the following composition: 20ml of 0.1mol / l CuSO 4 , 3.5ml Thioacetamide, 5ml NH4 OH and 40ml of 0.04mol / l (NH 3 ) 2 CS solution. Submerge the substrate in the precursor solution and seal the container. Then put it into a water bath, control the temperature at 60±1°C, take out the film after 3 hours of nucleation and growth, wash it with deionized water and dry it naturally. The thickness of the film prepared under this condition is 77nm, and the chemical composition is Cu 1.82 S. The SEM photos of the film surface and cross-section are shown in Figure 3 and Figure 4, respectively. It can be seen that the film is uniform and continuous, and the surface is flat. Illustrate the Cu prepared by this example x S film is a transparent conductor with high appearance quality.

Embodiment 3

[0032] Using 3-mercapto-propyl-trimethoxysilane instead of 3-amino-propyl-trimethoxysilane in Example 1, the cleaning of the quartz glass substrate and the preparation process of the monomolecular film are the same as in Example 1. The preparation of the precursor solution is the same as in Example 2, the growth temperature of the film is 50±1° C., the growth time is 2 hours, and the rest of the process steps are the same as in Example 1. The transmittance of the film is equivalent to that of Example 1, and the relationship of the electrical conductivity with temperature is shown in FIG. 5 . As the temperature increases, the conductivity of the film increases, showing semiconducting properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com