Innocuity method for treating disused stuffing material

A technology of harmless treatment and fibrous materials, applied in chemical instruments and methods, waste fuels, sustainable biological treatment, etc., can solve problems such as non-existence, secondary pollution, etc., and achieve the effect of simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

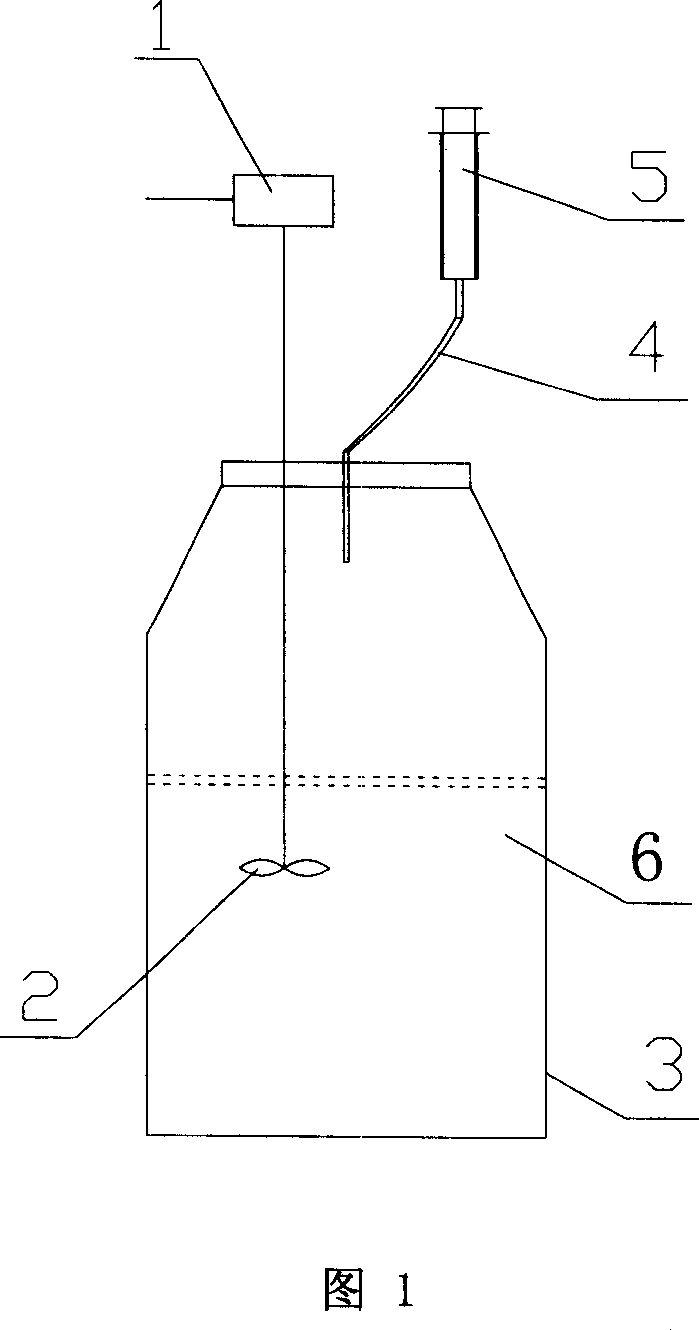

[0013] As shown in Figure 1, a kind of harmless processing method of waste packing, it comprises the following steps: the waste packing after being used as biofilm reactor packing by the saponin-containing natural plant hollow fiber material is placed in anaerobic fermentation tank 3 In the process, fill the anaerobic fermentation tank with water until the waste filler 6 is submerged, keep the fermentation tank at 10°C, DO (dissolved oxygen) = 0, and stir at a low speed for 1 day (15 rpm, the stirring device consists of a low-speed stirring motor 1, a low-speed stirring impeller 2), the waste fillers are completely degraded to generate biogas (introduced into the gas production indicator piston 5 from the gas production conduit 4 to measure the gas production), water and residue. The degraded residue can be used as microbial organic fertilizer.

Embodiment 2

[0015] As shown in Figure 1, a kind of harmless processing method of waste packing, it comprises the following steps: the waste packing after being used as biofilm reactor packing by the saponin-containing natural plant hollow fiber material is placed in anaerobic fermentation tank 3 In the process, fill the anaerobic fermentation tank with water until the discarded filler 6 is submerged, keep the fermentation tank at 30°C, DO (dissolved oxygen) = 0, and stir at a low speed for 5 days (15 rpm, the stirring device consists of a low-speed stirring motor 1, a low-speed stirring impeller 2), the waste fillers are completely degraded to generate biogas (introduced into the gas production indicator piston 5 from the gas production conduit 4 to measure the gas production), water and residue. The degraded residue can be used as microbial organic fertilizer.

Embodiment 3

[0017] As shown in Figure 1, a kind of harmless treatment method of waste packing, it comprises the following steps: the waste packing after being used as biofilm reactor packing by the saponin-containing natural plant hollow fiber material is placed in anaerobic fermentation tank 3 In the process, fill the anaerobic fermentation tank with water until the waste filler 6 is submerged, keep the fermentation tank at 50°C, DO (dissolved oxygen) = 0, and stir at a low speed for 10 days (15 rpm, the stirring device consists of a low-speed stirring motor 1, a low-speed stirring impeller 2), the waste fillers are completely degraded to generate biogas (introduced into the gas production indicator piston 5 from the gas production conduit 4 to measure the gas production), water and residue. The degraded residue can be used as microbial organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com