High hydroscopicity resin production method

A technology of superabsorbent resin and manufacturing method, which is applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problems of difficult control, cumbersome process, and high cost, and achieve the effects of simple process, easy reaction, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

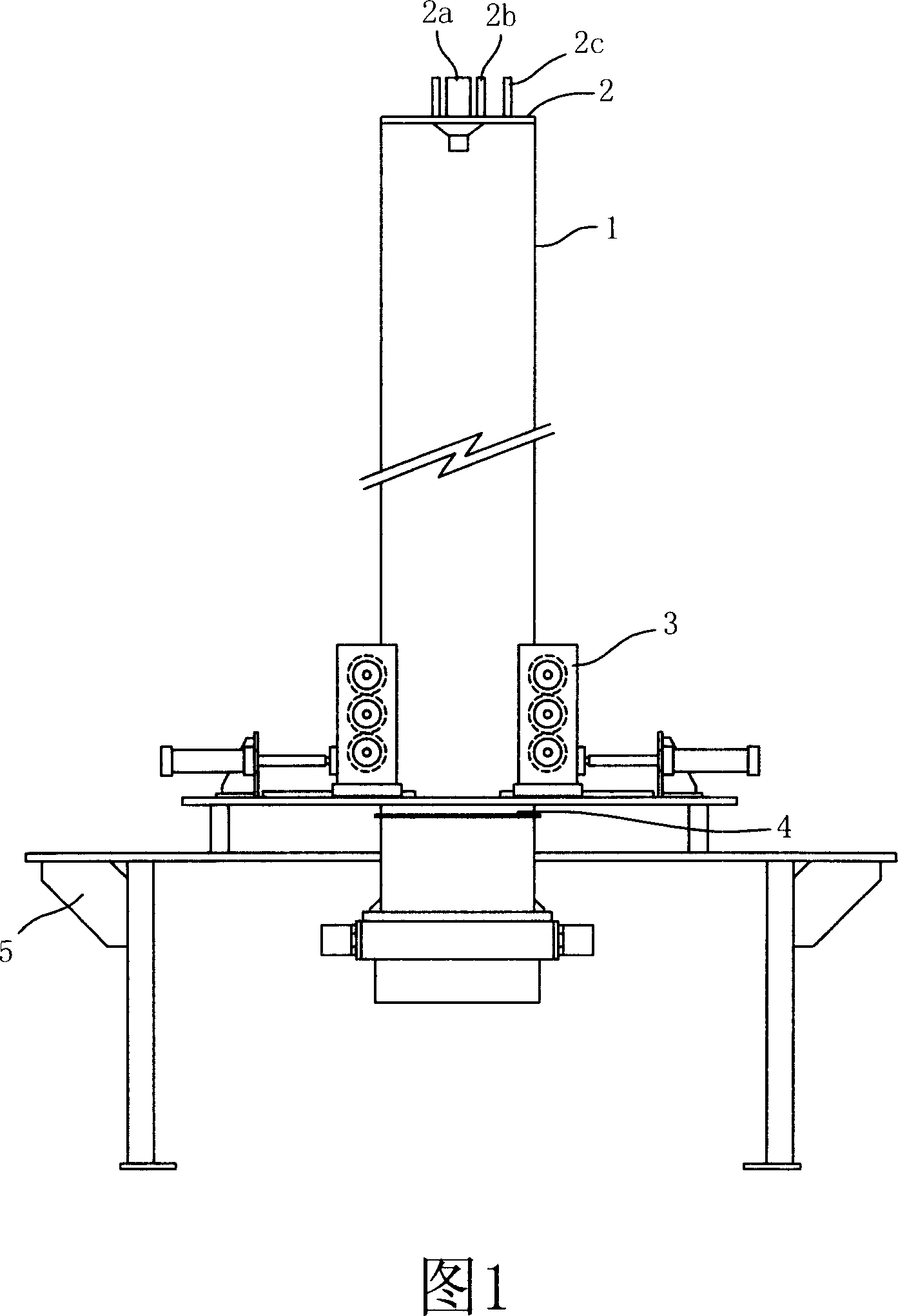

Image

Examples

Embodiment 1

[0064] 1) A 300mm×400mm×800mm cuboid reaction tank, the other specifications and operation methods are the same as those described in items 1 to 10 of the scope of the patent application. First add 17.35kg of 49% sodium hydroxide aqueous solution and 30.52kg of water into the 100L reaction tank, then slowly add 22.53kg of acrylic acid into the aqueous sodium hydroxide solution under ice bath for neutralization; at this time, the monomer concentration is 38.6wt % aqueous solution in which 68% (molar ratio) of acrylic acid is partially neutralized as sodium acrylate.

[0065] 2) Add 33.80 g of glycerol polyethylene glycol triglycidyl ether (n=7) to the partially neutralized acrylic acid aqueous solution, and maintain the temperature at about 20°C.

[0066] 3) Utilize quantitative pump (pump) with 1) the partly neutralized acrylic acid aqueous solution, L-ascorbic acid, sodium persulfate and 2.2-azobis(2-ylpropane) dihydrochloride respectively with 70.4kg The flows of / hr, 12.99...

example 2

[0072] Repeat Example 1, but step 2) is changed to use 33.80g of glycerol polyethylene glycol triglycidyl ether (n=12), all the other are the same as Example 1, superabsorbent resin can be obtained, and the measured holding power is 32.48g / g, 20g / cm 2 Water absorption rate under pressure 30.24g / g, 49g / cm 2 The water absorption rate under pressure is 21.76g / g, and the residual monomer is 127ppm.

example 3

[0074] Repeat Example 1, but step 2) is changed to add 33.80 g of glycerol polyethylene glycol triglycidyl ether (n=15), and the rest are the same as Example 1 to obtain a superabsorbent resin, and the measured retention force is 33.73 g / g , 20g / cm 2 Water absorption rate under pressure 32.78g / g, 49g / cm 2 The water absorption rate under pressure is 21.16g / g, and the residual monomer is 94ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption rate | aaaaa | aaaaa |

| Water absorption rate | aaaaa | aaaaa |

| Water absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com