Environment-friendly surface treatment method for aluminium profile before spray coating

A treatment method and front surface technology, applied in the direction of pretreatment surface, metal material coating process, device for coating liquid on the surface, etc. Short life and other problems, to achieve the effect of easy maintenance of production conditions, easy control of operation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

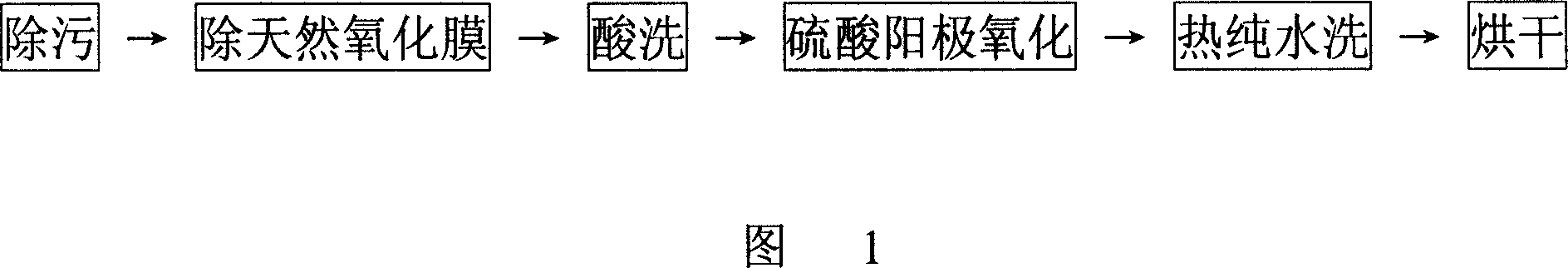

Method used

Image

Examples

Embodiment 1

[0018] Decontamination: According to the conventional aluminum metal surface decontamination process, for example, put the aluminum parts in 80 g / L sulfuric acid solution, and treat them at room temperature for 6 minutes.

[0019] Removal of natural oxide film: According to the conventional process of removing natural oxide film on the surface of aluminum metal, for example, put aluminum parts in 50 g / L sodium hydroxide solution and treat at 60 ° C for 10 minutes.

[0020] Pickling: According to the conventional aluminum metal surface pickling process, for example, put the aluminum parts in a 160 g / L nitric acid solution and treat it at room temperature for 5 minutes.

[0021] Sulfuric acid anodizing: use pre-treated clean aluminum parts as anodes, and immerse them in an electrolyte solution containing 180 g / L sulfuric acid and 5 g / L aluminum ions, with a working voltage of 13 volts and an electrolysis temperature of 22 °C for 22 minutes. Make the aluminum surface obtain an an...

Embodiment 2

[0025] Decontamination: According to the conventional aluminum metal surface decontamination process, for example, put the aluminum parts in 90 g / L sulfuric acid solution and treat them at room temperature for 5 minutes.

[0026] Removal of natural oxide film: According to the conventional process of removing natural oxide film on the surface of aluminum metal, for example, put aluminum parts in 60 g / L sodium hydroxide solution and treat at 55 ° C for 9 minutes.

[0027] Pickling: According to the conventional aluminum metal surface pickling process, for example, put the aluminum parts in 170 g / L nitric acid solution, and treat it at room temperature for 4 minutes.

[0028] Sulfuric acid anodizing: use pre-treated clean aluminum parts as anodes, and immerse them in an electrolyte solution containing 190 g / L sulfuric acid and 10 g / L aluminum ions, with a working voltage of 15 volts and an electrolysis temperature of 20°C for 18 minutes. Make the aluminum surface obtain an anodi...

Embodiment 3

[0032] Decontamination: According to the conventional aluminum metal surface decontamination process, for example, put the aluminum parts in 100 g / L sulfuric acid solution, and treat them at room temperature for 4 minutes.

[0033] Removal of natural oxide film: According to the conventional process of removing natural oxide film on the surface of aluminum metal, for example, put aluminum parts in 70 g / L sodium hydroxide solution and treat at 60 ° C for 8 minutes.

[0034] Pickling: according to the conventional aluminum metal surface pickling process, for example, put the aluminum parts in 180 g / L nitric acid solution, and treat it at room temperature for 3 minutes.

[0035] Sulfuric acid anodizing: use pre-treated clean aluminum parts as anodes, and immerse them in an electrolyte solution containing 200 g / L sulfuric acid and 15 g / L aluminum ions, with a working voltage of 18 volts and an electrolysis temperature of 18°C for 15 minutes. Make the aluminum surface obtain an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com