Process for increasing throughput of corn for oil extraction

A technology for corn oil and high-oil corn, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, waste fuels, etc., can solve the problems of lack of various or all valuable components of endosperm fractions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

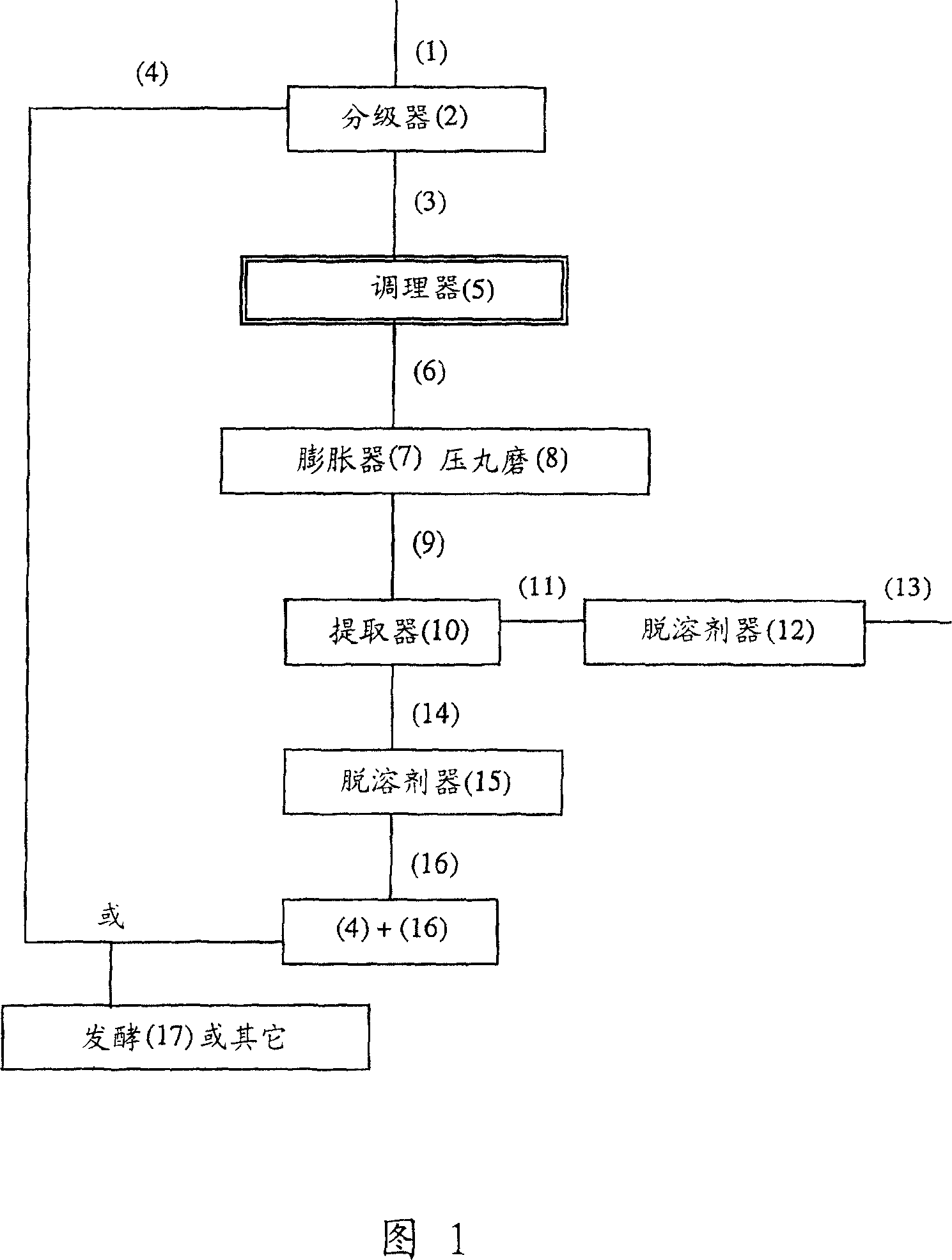

Embodiment 1

[0133] U.S. Patent Nos. 6,313,328 and 6,388,110 describe a commercial-scale process for processing whole corn kernels having a total oil content of at least about 8% by weight, the method comprising flaking the corn kernels and removing the germinated corn kernels from the germinated corn kernels. Steps to extract corn oil. US Patent No. 6,610,867 describes a method of extracting corn oil to form corn flour. The process generally includes the steps of cracking whole kernel corn having a total oil content of from about 3% to about 30% by weight, and extracting corn oil from the cracked corn kernels (no flaking is used in this process). All components of the whole grain (whatever form) including those that are low in oil are subjected to an extraction step. In contrast, in the present method, fractionation produces a high oil fraction and a low oil fraction. The low oil fraction bypasses the extraction process and can go directly to feed or other uses. Only the high oil fract...

Embodiment 2

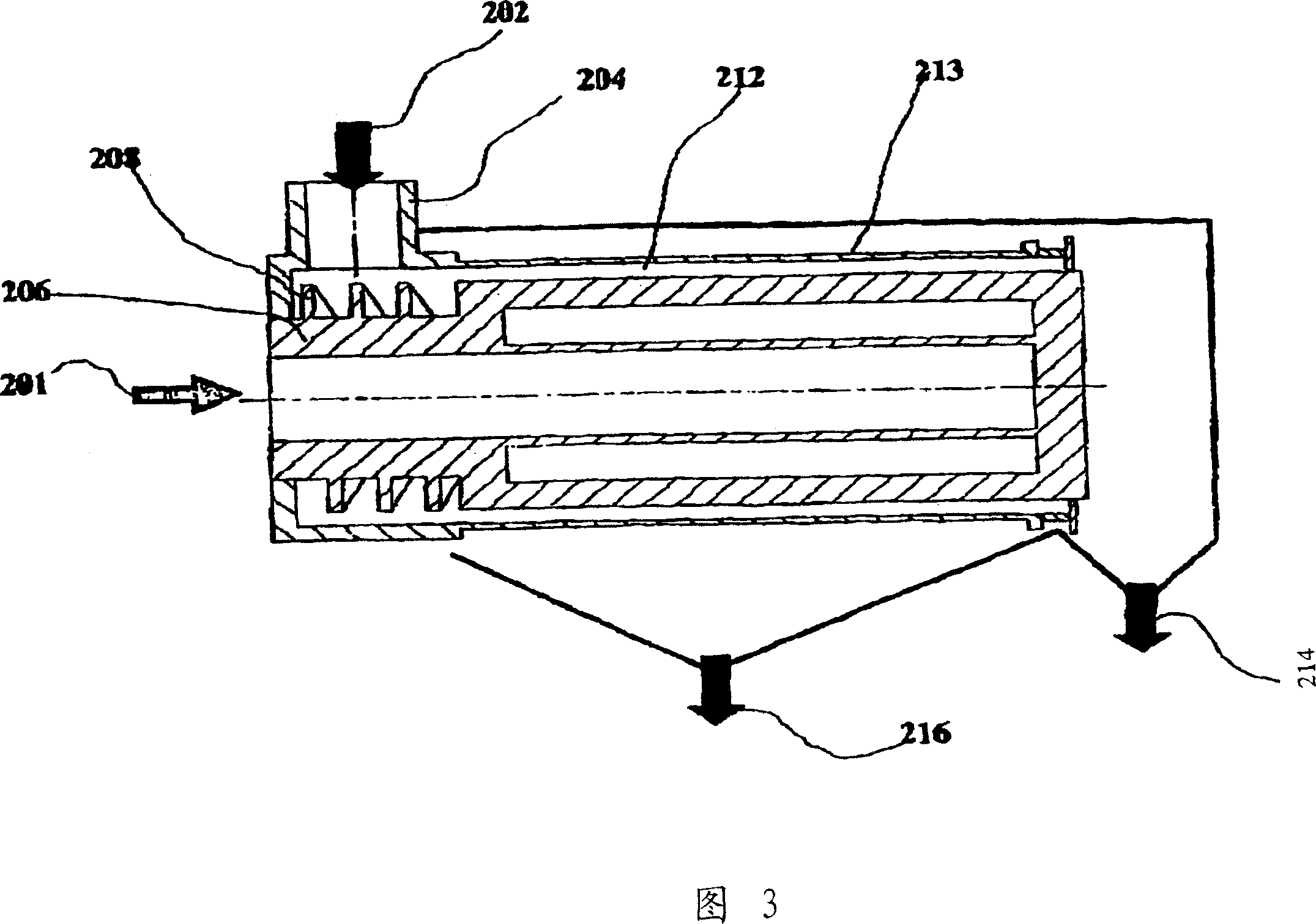

[0135] High oil corn grain 1 (LH310 (inbred, Holdens FoundationSeeds) x HOI001, see U.S. Patent Publication Nos. 2003 / 018269 and 2003 / 0172416, incorporated herein by reference) and high oil corn grain from storage Kernel 2 (Top Cross Blend seed corn purchased Spring 2003, grain harvested Fall 2003, Indiana) was metered into a steam jacketed agitating mixer with a residence time of approximately 7 minutes. The corn was heat tempered at 90°F. The conditioned corn is then transported to a Buhler-L facility (Buhler GmbH, Germany) where the hulls and softer tissues are rubbed to become a low oil fraction ("LOF") and separated from a high oil fraction ("HOF") . The results of the analysis of grain, HOF and LOF are shown in Table 4.

[0136] Table 4

[0137] moisture

[0138] These results show that oil levels were reduced to less than 2.5% by weight of LOF in more than half of the corn material, allowing this fraction to bypass costly extraction steps.

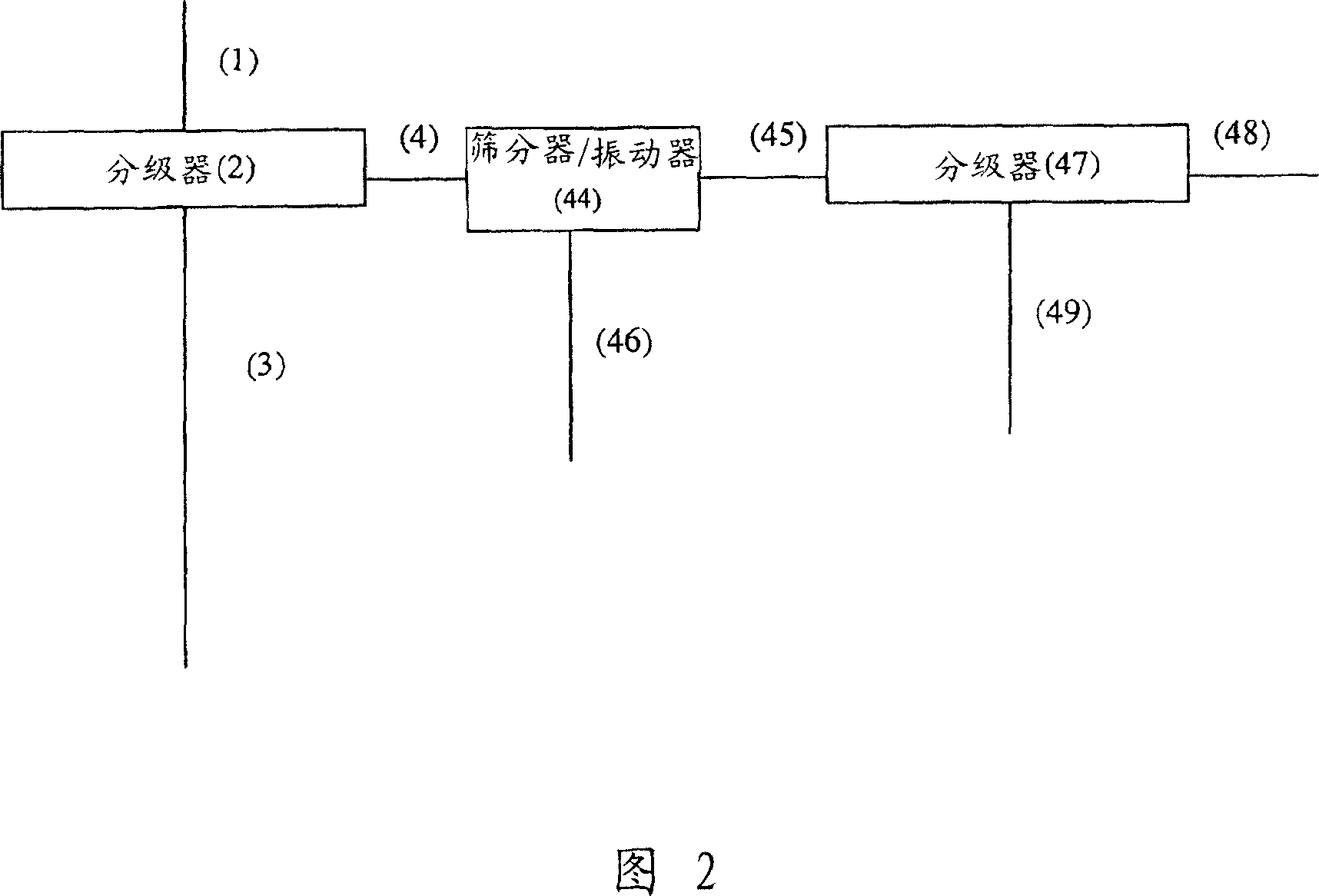

Embodiment 3

[0140] High oil corn grain 1 from Example 2 was conditioned as in Example 1 and then fed to a rice Roskamp Series 900 Breaker Mill drum (Roskamp, Waterloo, IA). The drum has six teeth per inch in a round bottom V-shaped design. The upper roller gap is set to 2.5mm, and the lower roller gap is set to 2.5mm. The broken conditioned corn material is then suctioned to remove the bran. The crushed conditioned bran-free corn material was then transported to the Buhler-L apparatus described in Example 1 for grading. The analysis results of grain, bran, HOF and LOF are shown in Table 5.

[0141] table 5

[0142] moisture

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com