Coke oven gas adsorption reinforced catalytic hydrogen producing process and apparatus

A coke oven gas and catalytic reaction technology, applied in hydrogen separation, chemical recovery, using solid contact hydrogen separation, etc., can solve the problems of increasing pressure swing adsorbent load, heat loss, long process, etc., to extend service life, reduce load, reduce the effect of the process of pre-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

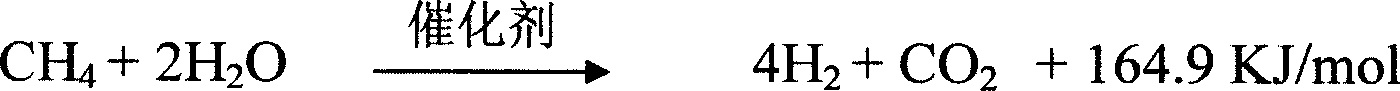

[0043] Example 1 Preparation of NiO-containing catalyst particles

[0044] First add 33ml of aluminum sol with a solid content of 10% into a beaker, add 20 grams of 20% nickel nitrate solution, mix well, infrared dry, extrude, dry, and calcinate for later use.

Embodiment 2

[0045] Example 2 Preparation of NiO-containing catalyst particles

[0046] First add 33ml of silica sol with a solid content of 20% into a beaker, add 30 grams of 20% nickel nitrate solution, mix well, infrared dry, extrude, dry, and calcinate for later use.

Embodiment 3

[0047] Example 3 Preparation of Adsorbent Particles

[0048] First add 20 grams of micron calcium carbonate powder into a beaker, then add 50 ml of aluminum sol with a solid content of 10%, add a small amount of water, stir and mix, then infrared dry, extrude, dry, and calcinate for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com