Method for producing high polymer polyacrylamide adapted to paper-making black liquor processing

A technology of polyacrylamide and its manufacturing method, which is applied in papermaking, textile and papermaking, fiber raw material processing, etc., can solve the problems of obvious degradation of polyacrylamide, and achieve the effect of meeting the processing requirements and solving the obvious degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

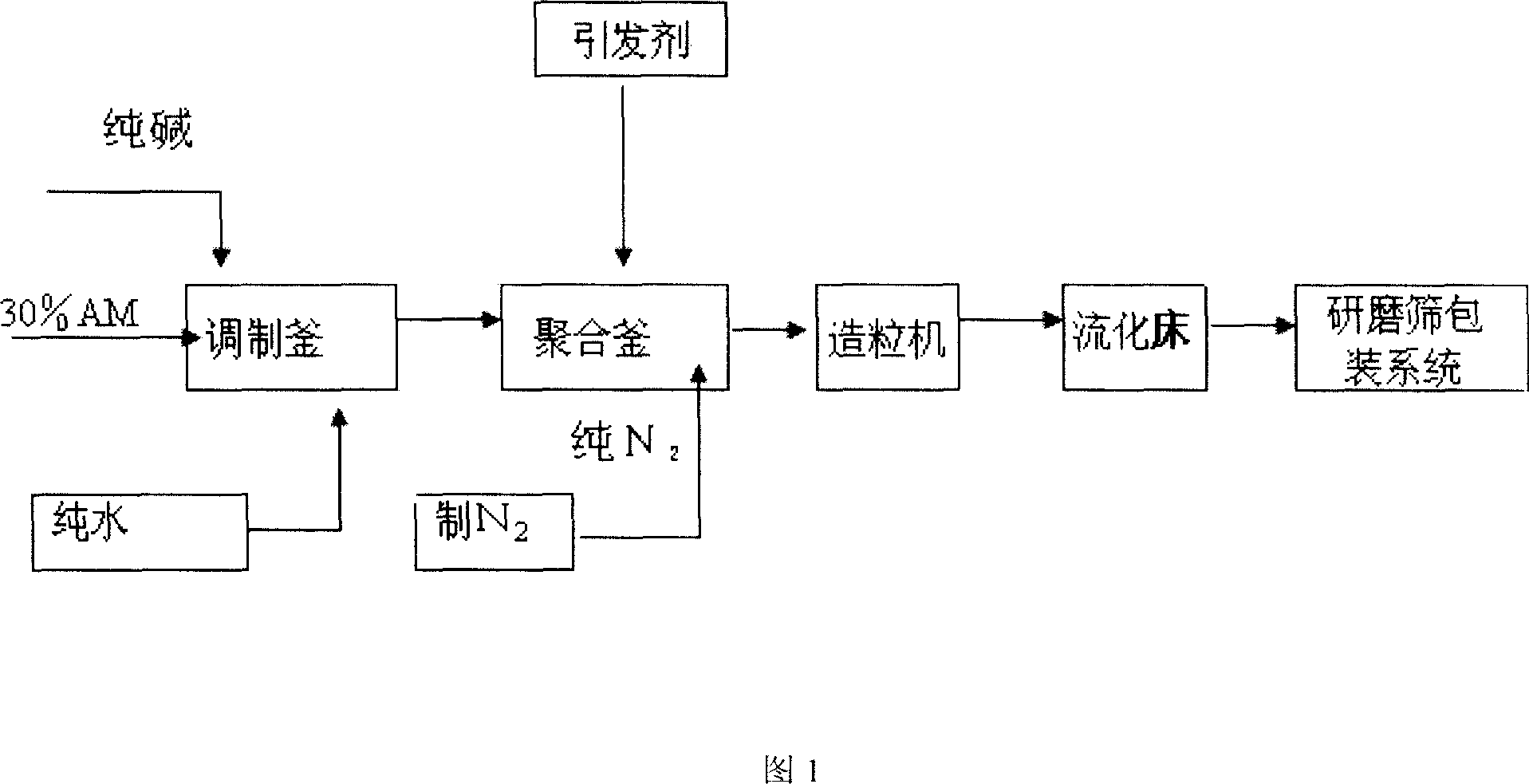

[0014] In conjunction with accompanying drawing, the present invention is further described:

[0015] Pure water is added to the refined acrylamide monomer in the preparation kettle to adjust the concentration to 21.0-25.0%, and soda ash with a pure monomer content of 9-14% is uniformly added to the preparation kettle. And feed the refrigerant water or steam to adjust the temperature of the monomer solution to 5-12 degrees. The monomer solution is sent into the polymerization tank, and the pressure is above 0.4Mpa, and the nitrogen gas with a purity of 99.95% is introduced. After 15 minutes, add disodium EDTA solution and sodium formate solution. After nitrogen gas for 10 minutes, add the prepared initiator, after nitrogen gas for 10 minutes, add potassium persulfate solution, after nitrogen gas for 15 minutes, add the prepared sodium bisulfite solution, after nitrogen gas for 25 minutes, close the polymerization kettle When the nitrogen pressure in the polymerization kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com