Bi-maleimide self-lubricating nano-composite material and its production

A technology of bismaleimide and nanocomposite materials, which is applied in the direction of lubricating compositions, base materials, petroleum industry, etc., can solve the problems that the dispersion uniformity of nanoparticles is not very good and affects the tribological properties of materials, etc., to prevent Settlement, improvement of interface bonding degree, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

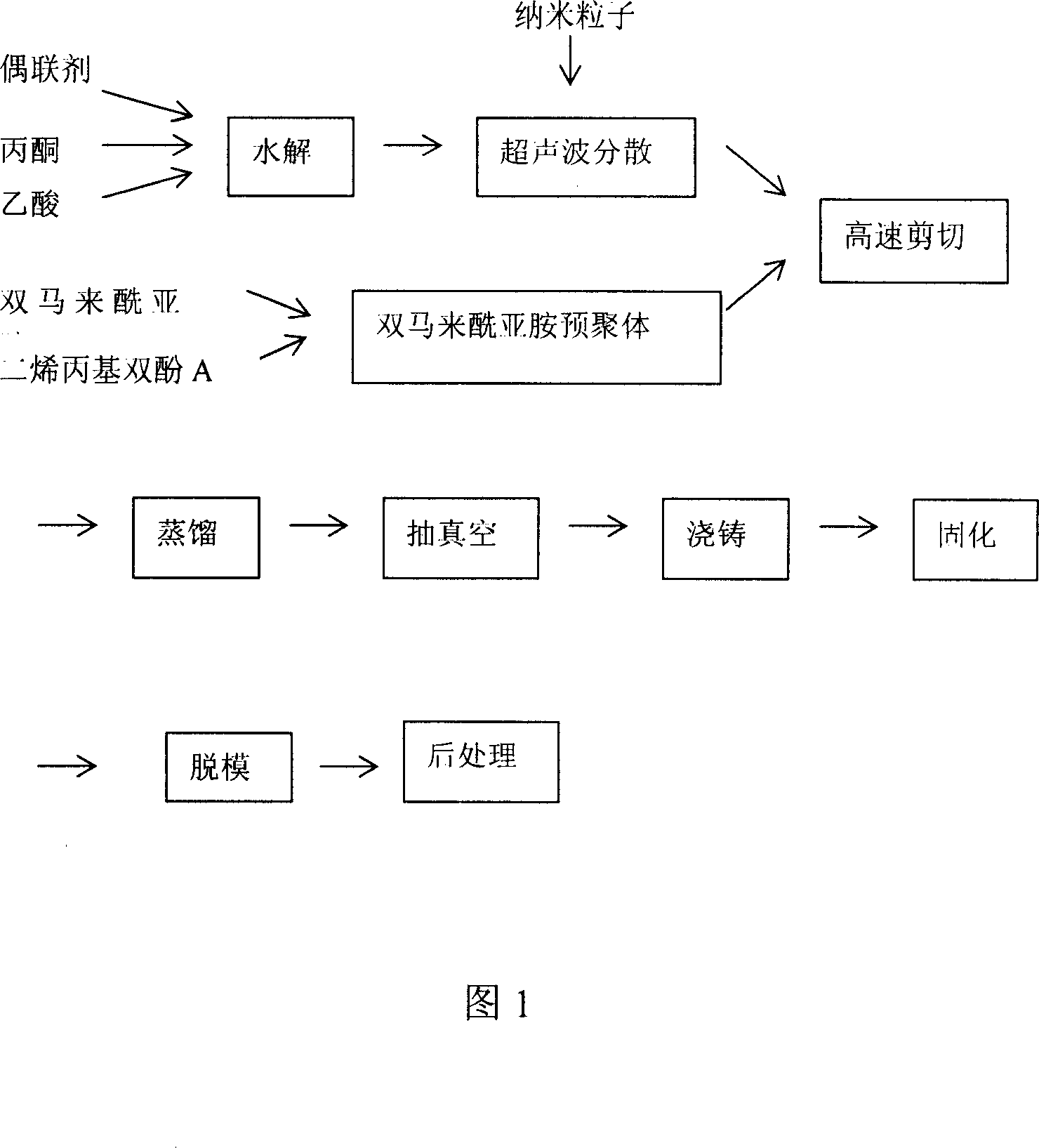

[0027] Add 0.5 parts of coupling agent γ-aminopropyltriethoxysilane to acetone, adjust the pH value with acetic acid, after the γ-aminopropyltriethoxysilane is hydrolyzed, add 2 parts of nano silicon nitride, 1 Add 1 part of nano-silica and 1 part of carbon black into the acetone solution containing the coupling agent, and disperse for 15 minutes by ultrasonic waves. Then it was added to 100 parts of bismaleimide resin prepolymer, heated and stirred by a high-speed homogeneous mixer for 15 minutes, added to a three-necked flask, heated and stirred for 30 minutes, and the acetone was removed by distillation. After evaporation, it is poured into a preheated mold, vacuumed to remove air bubbles, and then placed in an oven for curing. The curing process is as follows: after curing at 150°C for 2 hours, the temperature is raised to 180°C for 2 hours, and then the temperature is raised to 220°C for 4 hours. After natural cooling to room temperature and demoulding, the final post-tr...

Embodiment 2

[0029] Add 0.3 parts of coupling agent N-β(aminoethyl)-γ-aminopropyltrimethoxysilane into acetone, adjust the pH value with acetic acid, and after the coupling agent is hydrolyzed, add 2 parts of nano-silicon nitride, 2 parts of nano-silica were added to the acetone solution containing the coupling agent, and dispersed by ultrasonic waves for 20 minutes. Then it was added to 100 parts of bismaleimide resin prepolymer, heated and stirred by a high-speed homogeneous mixer for 20 minutes, added to a three-necked flask, heated and stirred for 40 minutes, and the acetone was removed by distillation. After evaporation, it is poured into a preheated mold, vacuumed to remove air bubbles, and then placed in an oven for curing. The curing process is as follows: after curing at 150°C for 2 hours, the temperature is raised to 180°C for 2 hours, and then the temperature is raised to 220°C for 4 hours. After natural cooling to room temperature and demolding, the final post-treatment was pe...

Embodiment 3

[0031] Add 0.2 parts of coupling agent N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane to acetone, adjust the pH value with acetic acid, and after the coupling agent is hydrolyzed, add 1 part of nano Silicon carbide, 2 parts of nano-silicon dioxide and 1 part of carbon black are added to the acetone solution containing the coupling agent, and dispersed by ultrasonic waves for 18 minutes. Then it was added to 100 parts of bismaleimide resin prepolymer, heated and stirred by a high-speed homogeneous mixer for 18 minutes, added to a three-necked flask, heated and stirred for 40 minutes, and the acetone was removed by distillation. After evaporation, it is poured into a preheated mold, vacuumed to remove air bubbles, and then placed in an oven for curing. After curing at 150°C for 2 hours, the temperature was raised to 180°C for 2 hours, and then the temperature was raised to 220°C for 4 hours. After cooling naturally to room temperature and demolding, the final post-treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com