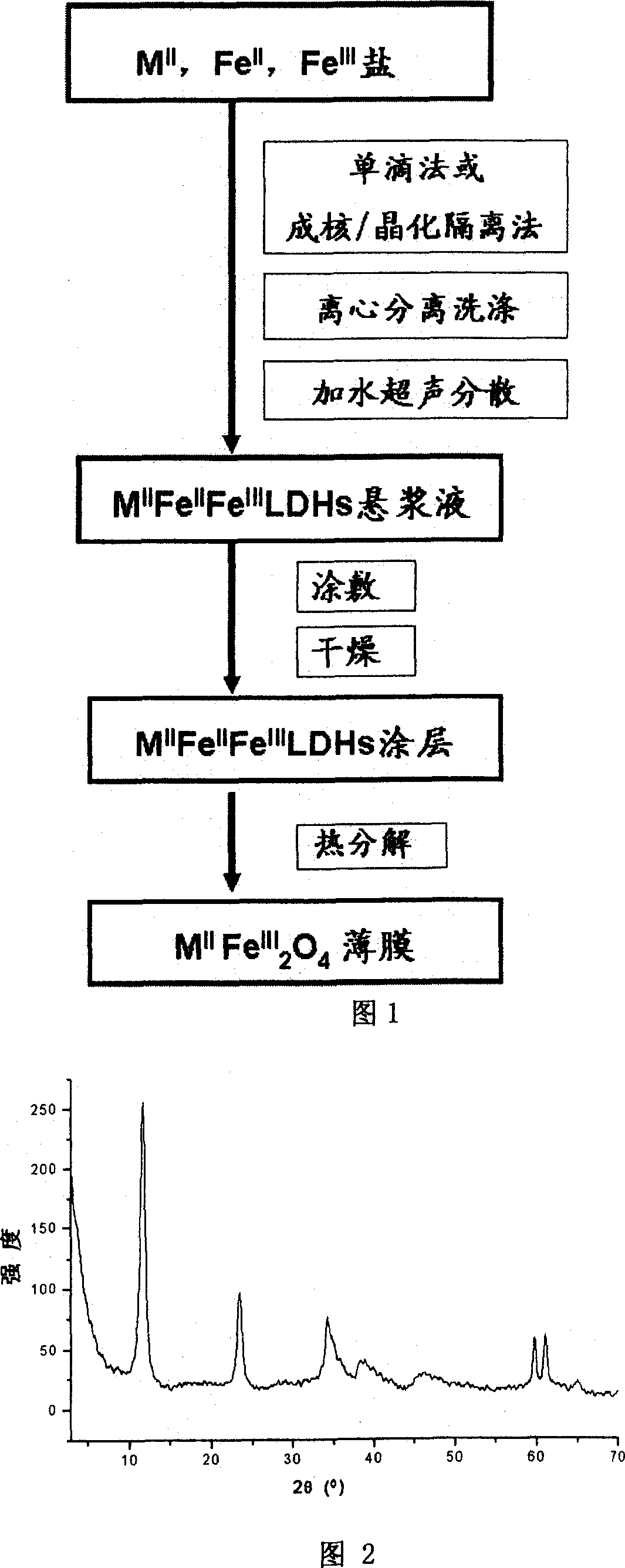

Process of thermally decomposing hydrotalcite-like coating to prepare stoichiometric ferrite film

A ferrite thin film, stoichiometric technology, applied in the magnetic layer and other directions, can solve the problems of few precursor varieties, large film pores, environmental pollution, etc., and achieve easy control of reaction conditions, good magnetic properties, and low preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

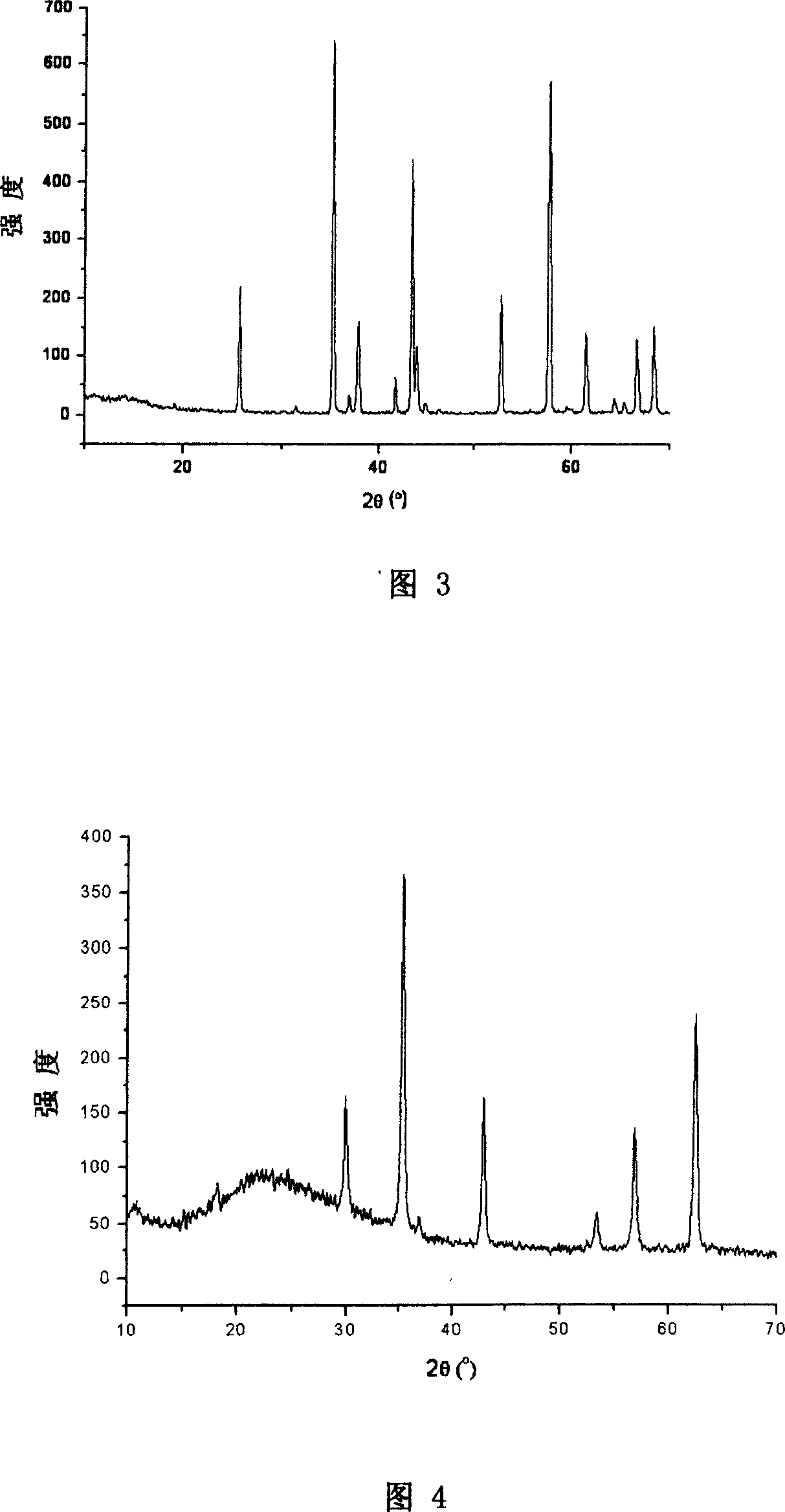

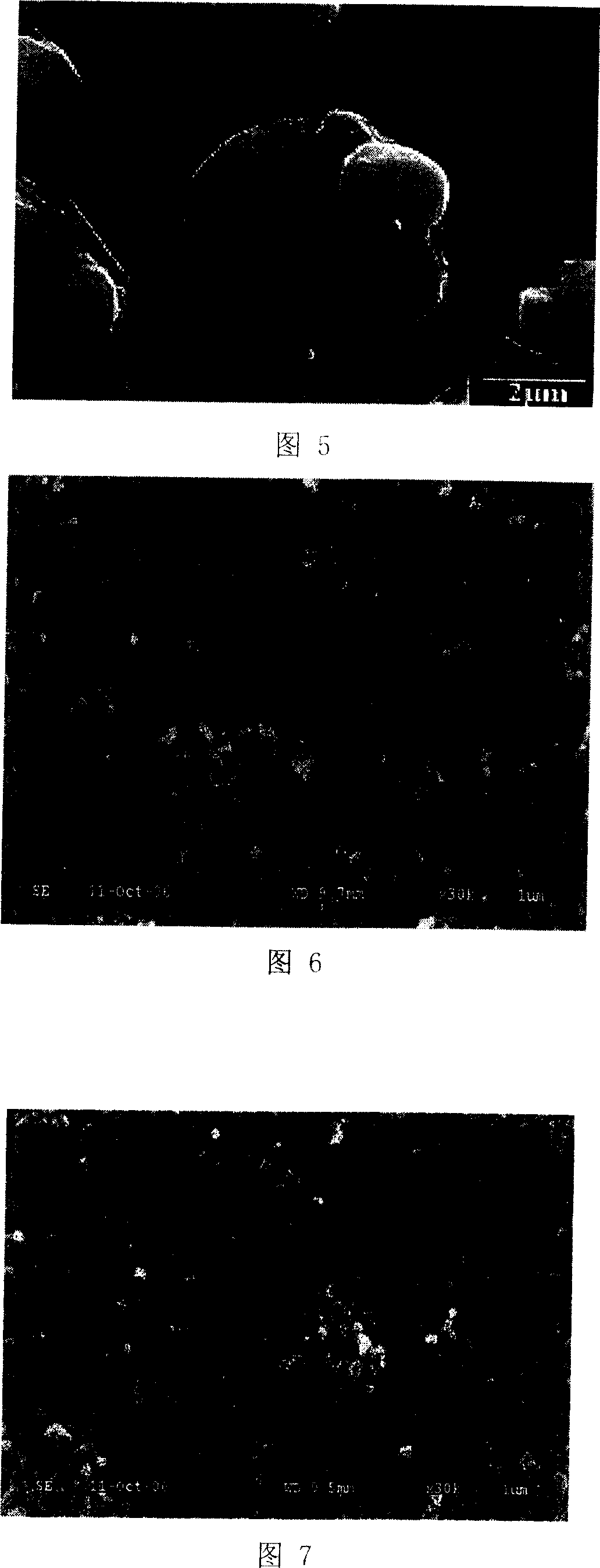

[0027] Mg(NO 3 ) 2 , FeCl 2 , Fe(NO 3 ) 3 The mixed salt solution, in which the metal ion concentration is: Mg 2+ 0.33mol / L, Fe 2+ 0.165mol / L, Fe 3+ 0.165 mol / L, and it was placed in a four-necked bottle; then, the alkali dripping salt single drop method was used to drip the mixed solution of sodium hydroxide and anhydrous sodium carbonate (wherein sodium hydroxide : 1.5mol / L, sodium carbonate: 0.7mol / L) until the system reaches a pH value of 11, crystallize in a water bath at 40°C for 15 hours, cool, centrifugally wash and separate, add water and ultrasonically disperse for 30 minutes, and prepare a particle size of 120- 130nm, stable MgFe II Fe III CO 3 LDH Serum. In order to monitor the preparation process and quality of the slurry, a small amount of slurry was taken out and dried, and analyzed by X-ray diffraction. As shown in Figure 2, MgFe II Fe III CO 3 (003), (006), (009) and (110), (113) and other characteristic diffraction peaks of LDH.

[0028] The abo...

Embodiment 2

[0032] Take 3.3×10 -2 mol of Mg(NO 3 ) 2 , 1.65×10 -2 mol of Fe(NO 3 ) 3 and 1.65×10 -2 mol FeCl 2 In the beaker, add 100ml and pass through N 2 deionized water, made into inorganic salt mixed liquid; take 1.5×10 -1 mol of NaOH and 7.0×10 -2 mol sodium carbonate, its mixture was dissolved in 100ml and passed through N 2 Alkaline solution in deionized water. Measure 70ml of lye and inorganic salt solution and add drop by drop quickly to the fully back-mixed rotating liquid film reactor for reaction. The slurry obtained after the reaction is crystallized in a water bath at 40°C for 15h under the protection of nitrogen, cooled, and centrifuged Wash and separate, add water and ultrasonically disperse for 30 minutes, and prepare a stable MgFe with a particle size of 120-130nm II Fe III LDH Serum.

[0033] Using the same conditions and methods as in Example 1, it is also possible to prepare MgFe with a thickness in the micron order, uniform, dense, and a single crystal ...

Embodiment 3

[0035] Prepare stable MgFe under the same conditions as in Example 2 II Fe III CO 3 LDH Serum. Using the slurry coating technology on the cleaned quartz substrate, a uniform and dense MgFe with a thickness of micron is prepared. 2 o 4 Stoichiometric ferrite films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Saturation magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com