Integrated hydrogen producing and storing process and apparatus

A hydrogen storage and electrochemical technology is applied in the field of integrated methods and devices for hydrogen production and hydrogen storage, which can solve the problems of adsorption capacity stability, adsorption pressure sensitivity, slow hydrogen absorption and desorption speed, and inability to meet the normal needs of gas filling stations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

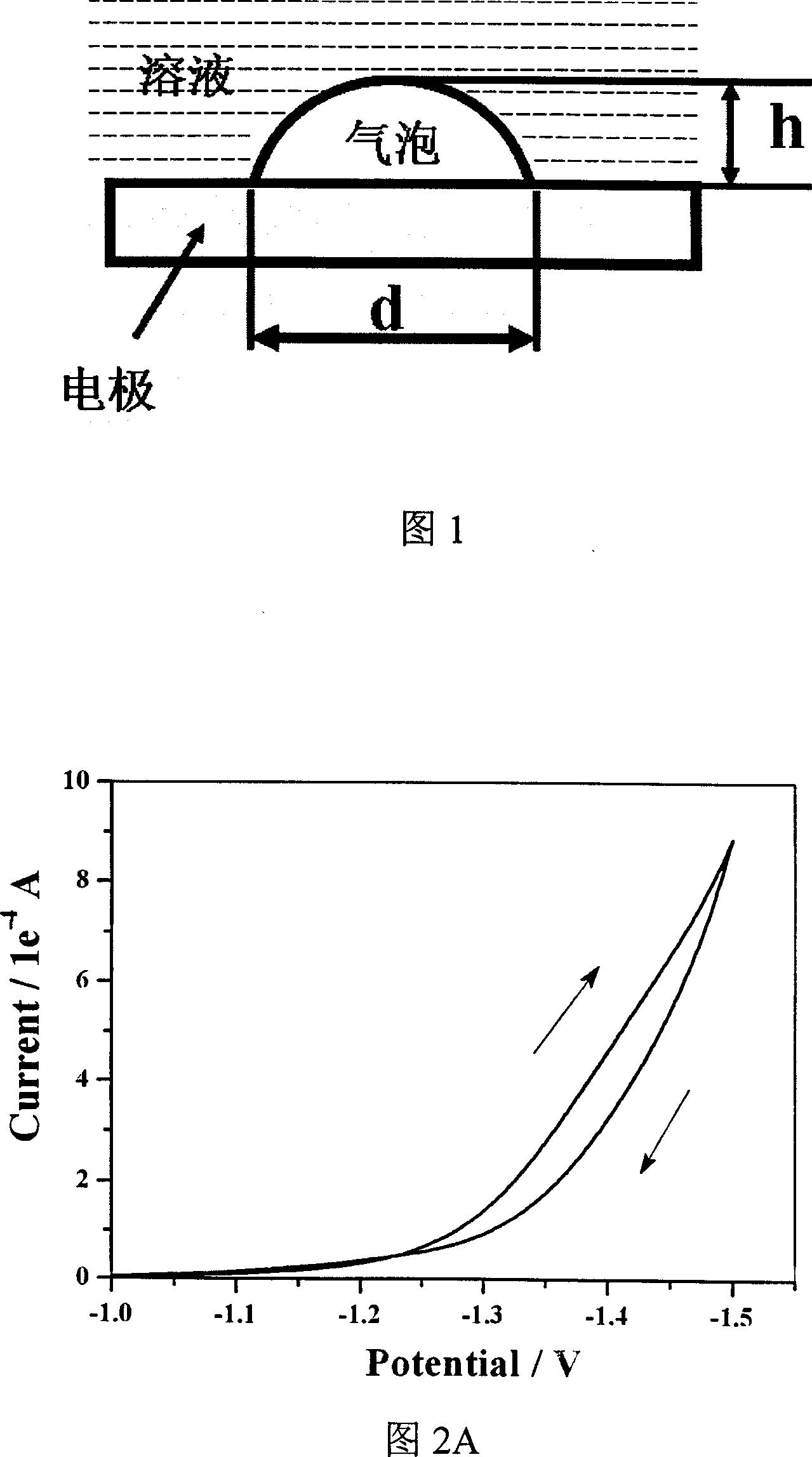

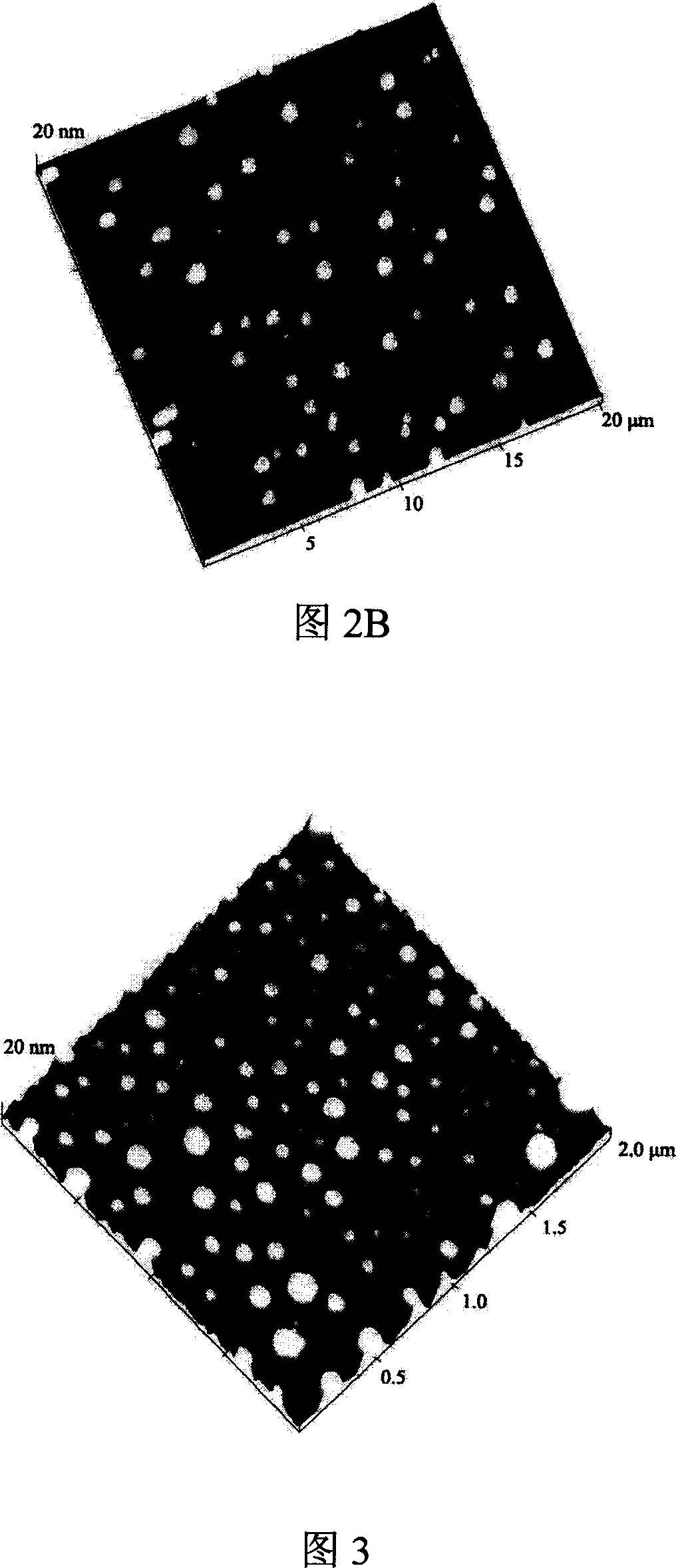

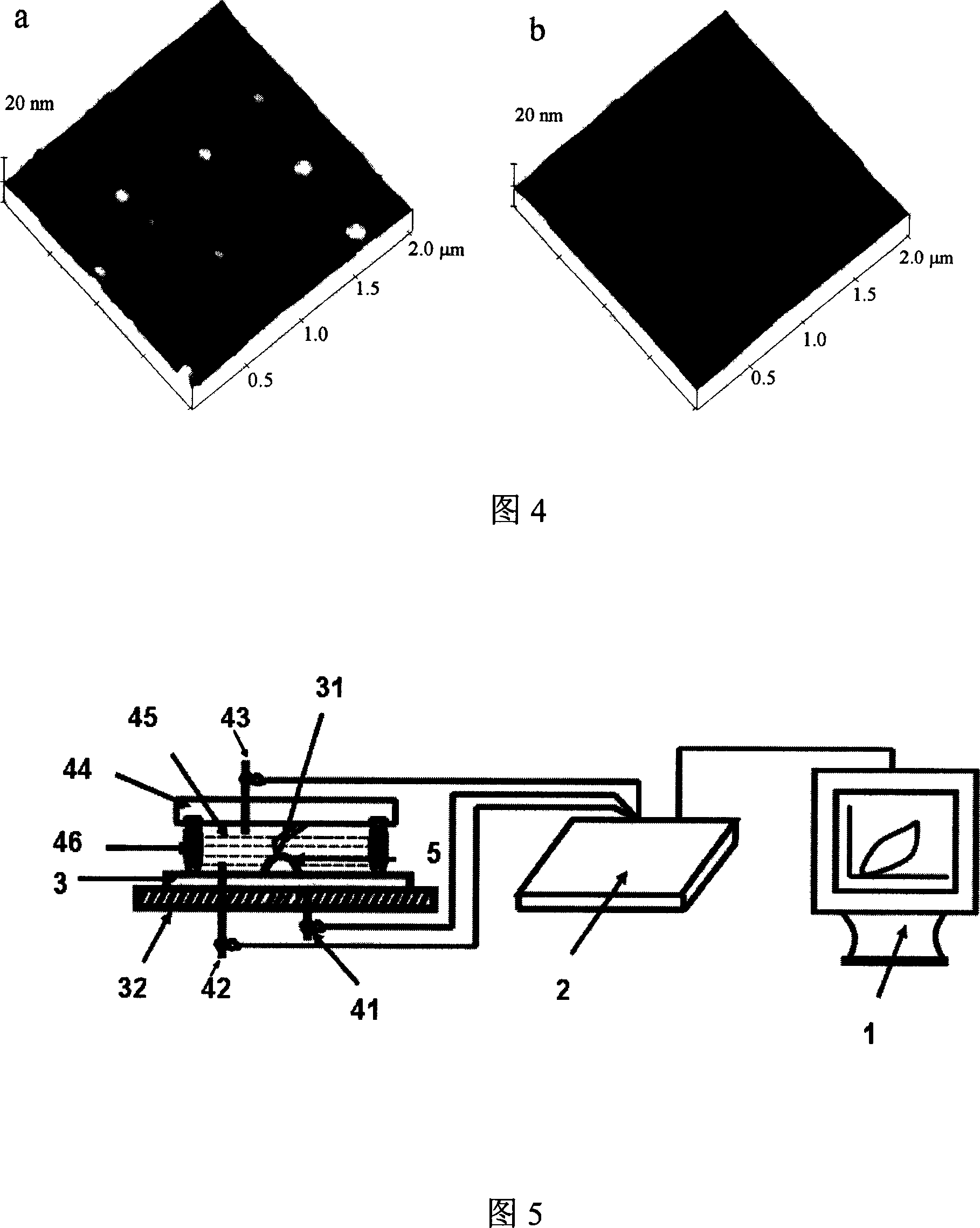

[0050] As shown in Fig. 5, a piece of 12mm×12mm high-order pyrolytic graphite 3 is used as a hydrogen storage device and AFM observation substrate to be glued on the AFM special magnet sheet 32 with conductive silver glue. Before use, use double-sided tape to peel off the graphite surface layer, and the magnet sheet with graphite 3 attached is attached to the stage (not shown) of the head of the atomic force microscope. Adjust the head position, and fix the AFM tip 31 on the AFM special liquid tank (liquid tank) 4 so that the tip 31 is about 40 μm away from the surface of the graphite substrate 3, and an O-ring 46 is fixed between the liquid tank 4 and the graphite substrate 3 to seal , The liquid tank 4 is also provided with a drain pipe (not shown). Quickly inject the pre-degassed 0.001-1.0mol / L diluted sulfuric acid electrolyte solution 45. Use an atomic force microscope to observe the morphology of the graphite surface before applying voltage as a control. The working electr...

Embodiment 2

[0058] The device and operation steps are the same as in Example 1, but using 0.001-1.0 mol / L potassium hydroxide solution as the electrolyte, the applied voltage range is -1.0V to -2.0V, and the time is 1-120 seconds. The height range of the obtained nanobubbles is 2-100nm.

[0059] The size of nanobubbles generated in 0.001-1.0 mol / L sodium nitrate, potassium nitrate, barium sulfate and other solutions is similar to that of sulfuric acid and potassium hydroxide solutions, so we will not give examples here.

Embodiment 3

[0061] As shown in Figure 6, the bottom of the electrochemical cell 4 is equipped with a hydrogen storage device high-order pyrolytic graphite 3, the graphite 3 is connected to the working electrode wire 41, and the bottom of the electrochemical cell 4 is also provided with a drain switch that can be opened and closed. 7. The reference electrode is placed in the above-mentioned electrolyte solution 45 through the side wall of the electrochemical cell 4. The top surface of the electrochemical cell is provided with an outlet 6 for the discharge of oxygen or hydrogen, and the counter electrode 43 is placed in the electrolyte solution through the outlet 6 45 in.

[0062] In the same way, the three-electrode clip of the electrochemical instrument 2 connected to the computer 1 is clamped to the corresponding electrodes to form the integrated hydrogen production and storage device of the present invention.

[0063] Same as Example 1 or 2, after a certain negative pressure is applied to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com