Method for preparing middle size or oligo-glucomannan using radiation method for degrading plump konnjaku fine powder

A technology of konjac glucomannan and konjac fine powder, applied in the direction of oligosaccharides, etc., can solve the problems of complex process, complicated separation and purification process, etc., and achieve the effect of simple process, high degradation rate and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

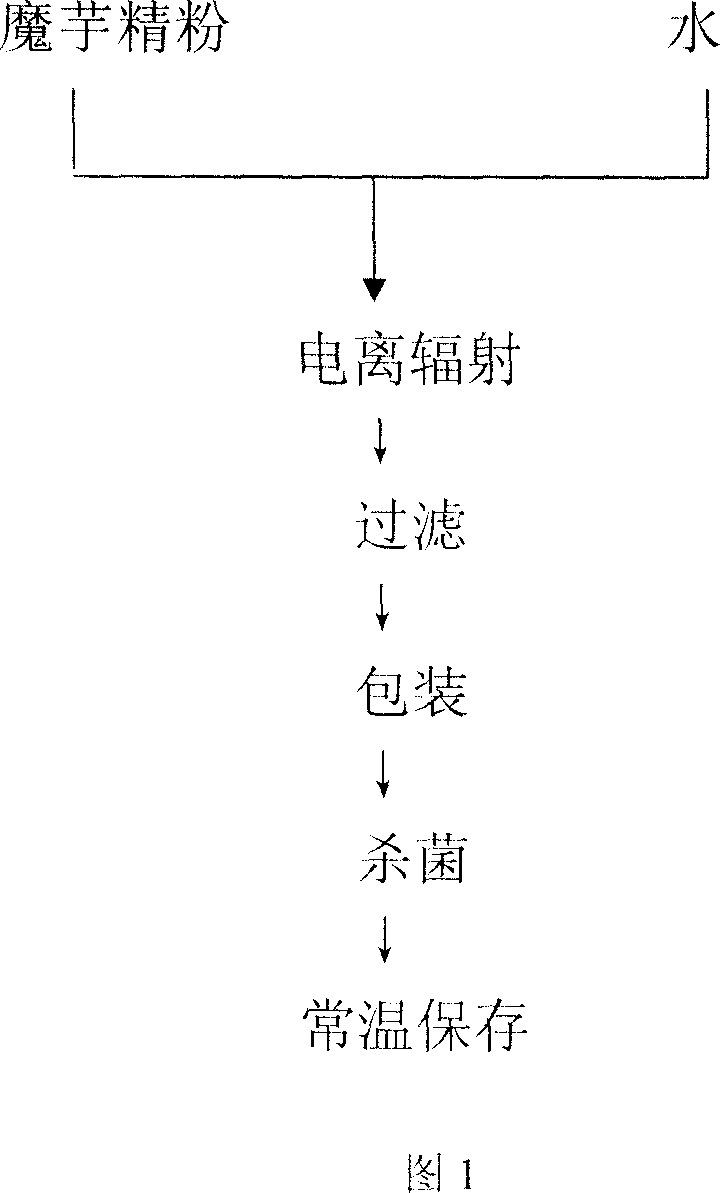

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Konjac fine powder is fully swollen with water under stirring, and the weight ratio of konjac fine powder and water is 1:40. After swelling, it is irradiated with cobalt-60 gamma rays with an absorbed dose of 6kGy. After irradiation, it is left to stand for 1.5 hours. The non-degradable matter settles to the bottom of the container, and the supernatant is released from the pipe at the middle and lower opening of the container to obtain the product. The product yield was 90.1% after analysis. The product is packaged in a hard container, sealed, sterilized in boiling water at 100°C, and stored at room temperature (usually room temperature) for a period of 24 months.

Embodiment 2

[0024] Embodiment 2: Konjac fine powder is fully swollen with 5 times the weight of water under stirring, and the pH value is adjusted with hydrochloric acid or sodium hydroxide, and the pH value is controlled within a range of 4.5±0.5. After swelling, it is irradiated with x-rays, and the absorbed dose is 4kGy. filter. The filtrate is packaged in a food flexible packaging bag, sealed, heat sterilized, and has a shelf life of 15 months at room temperature.

Embodiment 3

[0025] Embodiment 3: Konjac fine powder is fully swollen with 60 times the weight of water under stirring, and the pH value is adjusted with hydrochloric acid or sodium hydroxide, and the pH value is controlled within a range of 6±0.5. After swelling, it is irradiated with electron rays, and the absorbed dose is 6kGy. filter. The filtrate is the product. The product yield was 89.5% after analysis. The product is packaged in a food flexible packaging bag, sealed, heat sterilized, and has a shelf life of 18 months at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com