Preparation method of conductive high polymer and carbon nanotube composite electrode material

A carbon nanotube composite and conductive polymer technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve the problems of reducing polymer capacity, shrinking polymer volume, and increasing polymer film defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

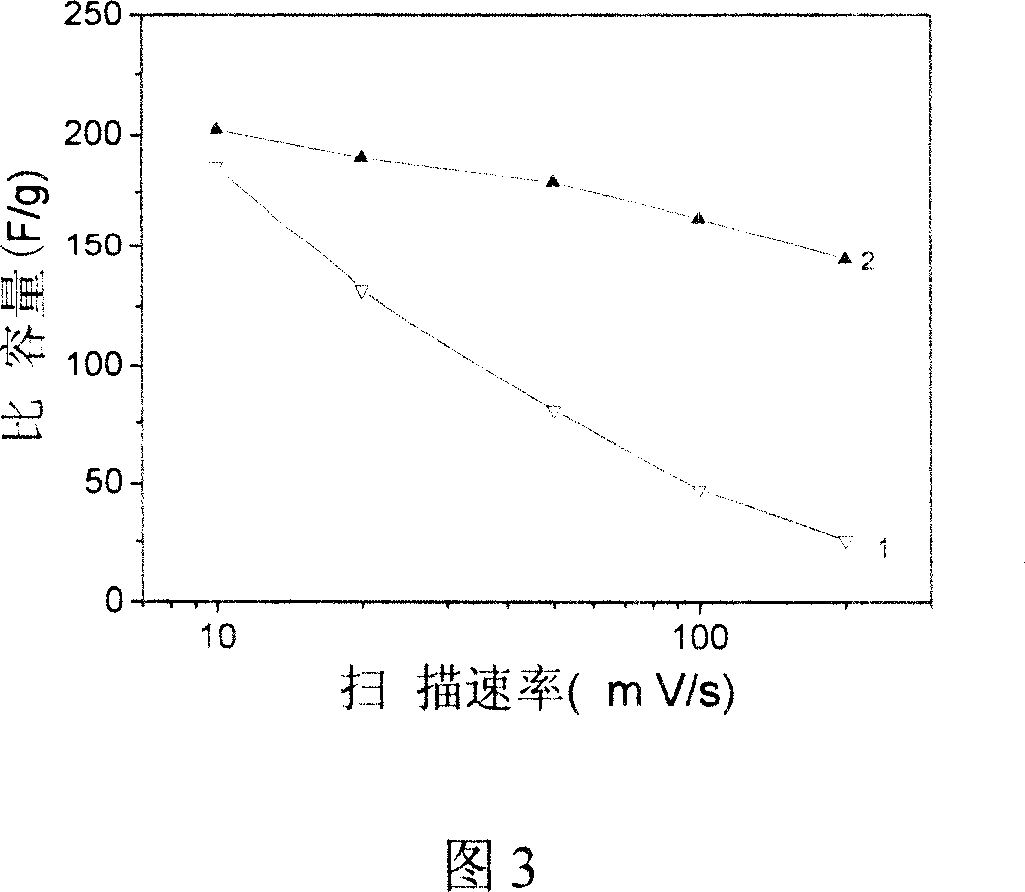

Image

Examples

Embodiment 1

[0012] Embodiment 1: first single-walled carbon nanotubes were ultrasonically oscillated in 0.6mol / L dodecylbenzenesulfonic acid solution for 5 minutes to obtain a dispersion A containing 0.01wt% of carbon nanotubes; Add conductive polymer monomer pyrrole to the diluted solution of A so that the concentration of conductive polymer monomer pyrrole is 0.6mol / L to prepare solution B; finally place the working electrode and counter electrode in solution B, and apply 10mA to the working electrode / cm 2 The current density is used for electrochemical polymerization. After the polymerization is completed, a uniform conductive polymer / carbon nanotube composite film can be obtained on the working electrode. The thickness of the composite film can be controlled by multiplying the polymerization electricity, that is, the polymerization current by the polymerization time. .

Embodiment 2

[0013] Embodiment 2: first multi-walled carbon nanotubes were ultrasonically oscillated in 0.2mol / L sodium dodecylbenzenesulfonate solution for 20 minutes to obtain a dispersion A containing 0.05wt% of carbon nanotubes; Or in the dilute solution of A, add conductive macromolecular monomer aniline to make the concentration of conductive macromolecular monomer aniline be 0.05mol / L; Then add chloride so that the concentration of chloride is 0.1mol / L to make solution B; The working electrode and the counter electrode are placed in solution B, and 8mA / cm is applied to the working electrode 2 The current density is used for electrochemical polymerization. After the polymerization is completed, a uniform conductive polymer / carbon nanotube composite film can be obtained on the working electrode. The thickness of the composite film can be controlled by multiplying the polymerization electricity, that is, the polymerization current by the polymerization time. .

Embodiment 3

[0014] Embodiment 3: first the single-walled carbon nanotubes were ultrasonically oscillated in 0.4mol / L potassium toluenesulfonate solution for 50 minutes to obtain a dispersion A containing 0.08wt% of carbon nanotubes; Add conductive polymer monomer thiophene to make the concentration of conductive polymer monomer thiophene 0.2mol / L in the diluted solution; then add perchlorate so that the concentration of perchlorate is 0.05mol / L to make solution B; Finally, place the working electrode and the counter electrode in solution B, and apply 5mA / cm to the working electrode 2 The current density is used for electrochemical polymerization. After the polymerization is completed, a uniform conductive polymer / carbon nanotube composite film can be obtained on the working electrode. The thickness of the composite film can be controlled by multiplying the polymerization electricity, that is, the polymerization current by the polymerization time. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com