Since these materials are electrically non-conductive, there are difficulties associated with the consistent earth grounding of the wood that is critical for the electrostatic spraying process.

However, this critical

moisture layer is only present for a short period of time.

Further, the

moisture that has risen to the

target surface is in limited supply, even though significant quantities of

moisture still reside within the substrate.

Therefore, the quantity of available moisture that can be rapidly driven to the surface is in very low supply.

Thin recessed areas in wood substrates

pose unique moisture problems.

Exposure to dry air over time causes the thin areas to lose their moisture faster than the thick areas.

Initially, both devices will

discharge the same

voltage, but the larger battery will require more time to completely drain.

In time, this can result in significant differences in total available

surface moisture content.

Unfortunately, the moisture content is typically in the range of greatest dissimilarity when it is desirable to

powder coat the wood substrate in question.

The unreliably uniform moisture content in the varying wood thickness has prevented the successful

powder coating application of many material objects.

This problem is a major inhibitor to the future success of powder coatings on many non-conductive wood products.

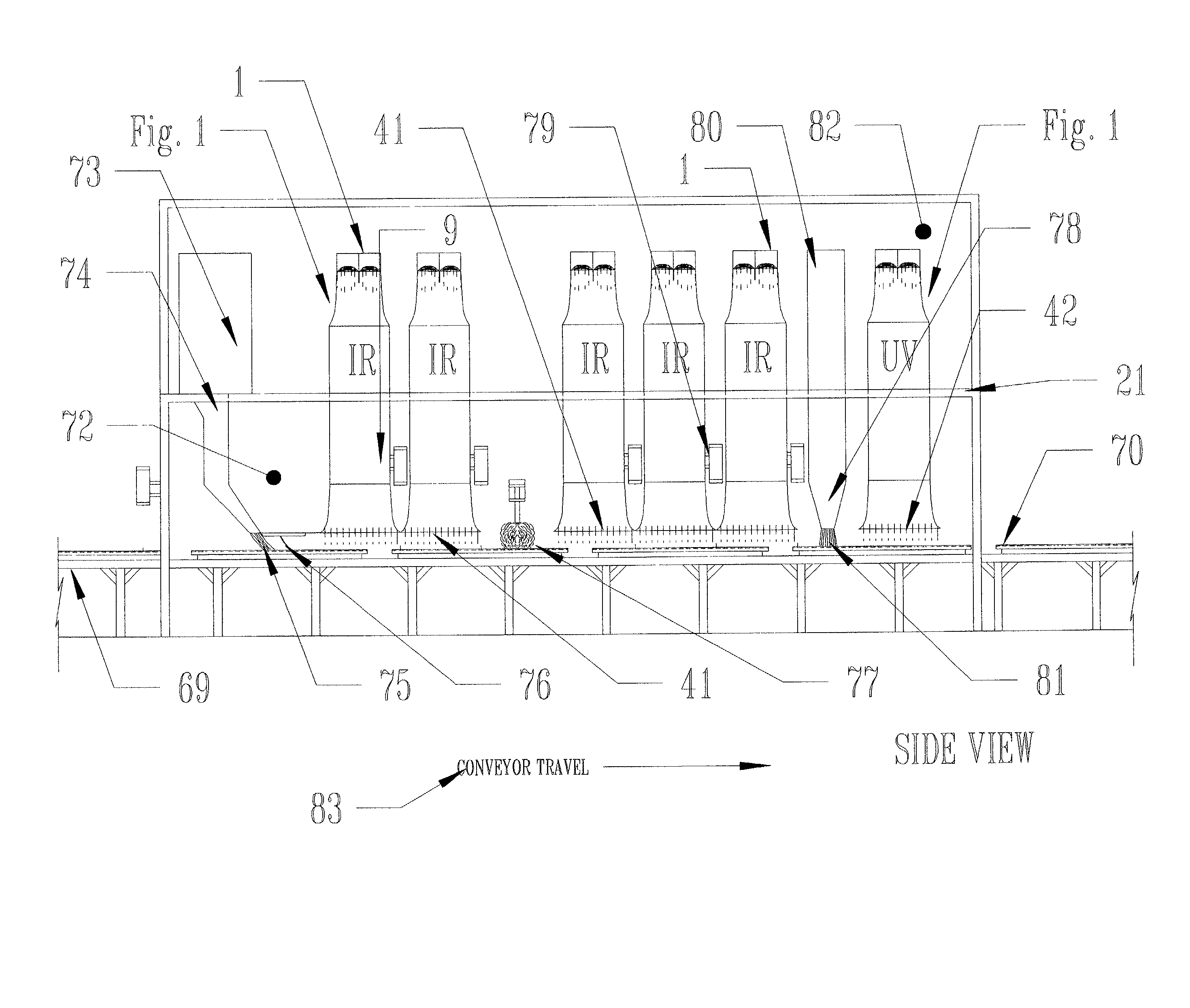

Powder processing

system designs currently adhere to the "separate equipment" mentality, and are burdened with unfavorable time lags between the heat processes and the application of the powder material to the substrate.

This is due to the significant distances that the parts in process must travel between separate pieces of processing equipment.

However, the substrate experiences a rapid surface

temperature drop during its travel through time and space before the powder is actually applied.

This procedure causes a variety of problems for maintaining uniformity of temperatures over the

substrate surface.

It can also cause an undesirable depletion of moisture, as well as the expulsion of natural wood resins (sap), from some substrates.

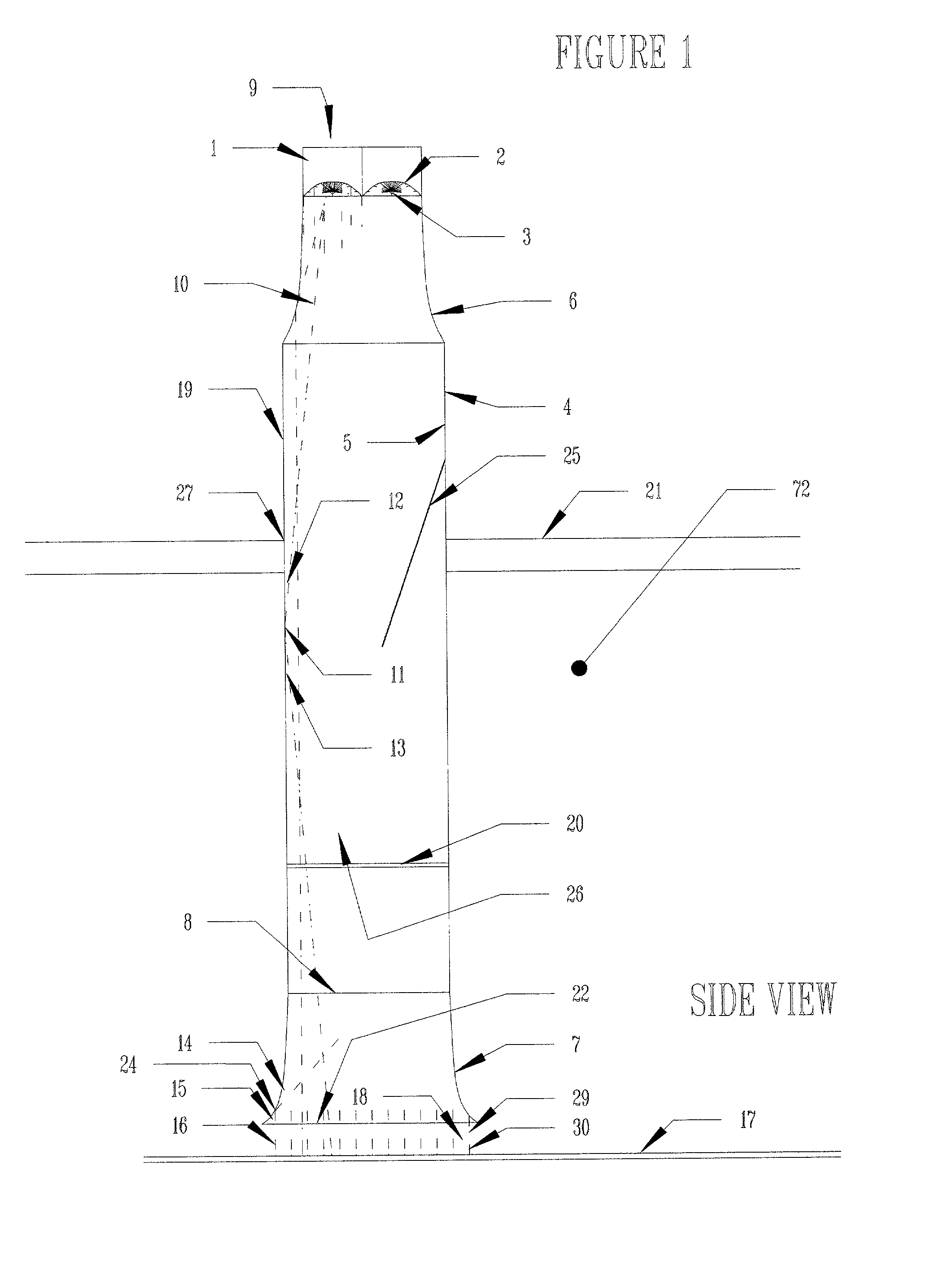

This is true because the absorption ability of IR

radiation by the wood surface is high, but its

thermal conductivity is considered to be very low.

However, this condition of uniformity will not remain for long periods of time, especially when the substrate must travel a significant distance through space and time to the

powder spray application.

It should be noted that the

atmosphere, including the chilled (or warm) moisture controlled fluid, does not efficiently absorb IR radiation.

Radiant losses from the heated surface typically exceed convective losses at elevated temperatures, such as 225.degree. F.

This

radiant energy loss rapidly decreases the surface temperature of the interface area of the wooden part in process.

Lengthy

travel time to separate processing equipment allows for a rapid decline of surface temperature because of the combination of radiant, convective and conductive losses.

This can create greater temperature anomalies if the

travel time to the next process is lengthy.

Greater temperature differentials between thick and thin parts can then result, causing a

chain reaction of events that negatively affect the powder process.

The area between the preheat oven process and the

powder spray application equipment is often designated as a hazardous area, and does not possess the atmospheric thermal properties or processing equipment that is required to maintain the surface temperature of the substrate.

It has been observed that some types of wood products incur damage from thermal expansion, such as

cracking or splitting of the substrate, when attempting to achieve

high surface temperatures relative to the inner substrate temperature.

These characteristics cause the

wood product to experience a large surface temperature increase in a small period of time when exposed to only modest power levels of

infrared radiation.

This method is inefficient because the rate of temperature rise, and the resulting thermal expansion differential, is well below the maximum allowable limit.

The artificially high

set point temperature that is used to compensate for the aforementioned surface

temperature drop during conveyor travel also complicates the thermal expansion aspect in this process.

Current regulations prohibit the installation of certain heat and / or

radiation processing equipment within the spray booth area.

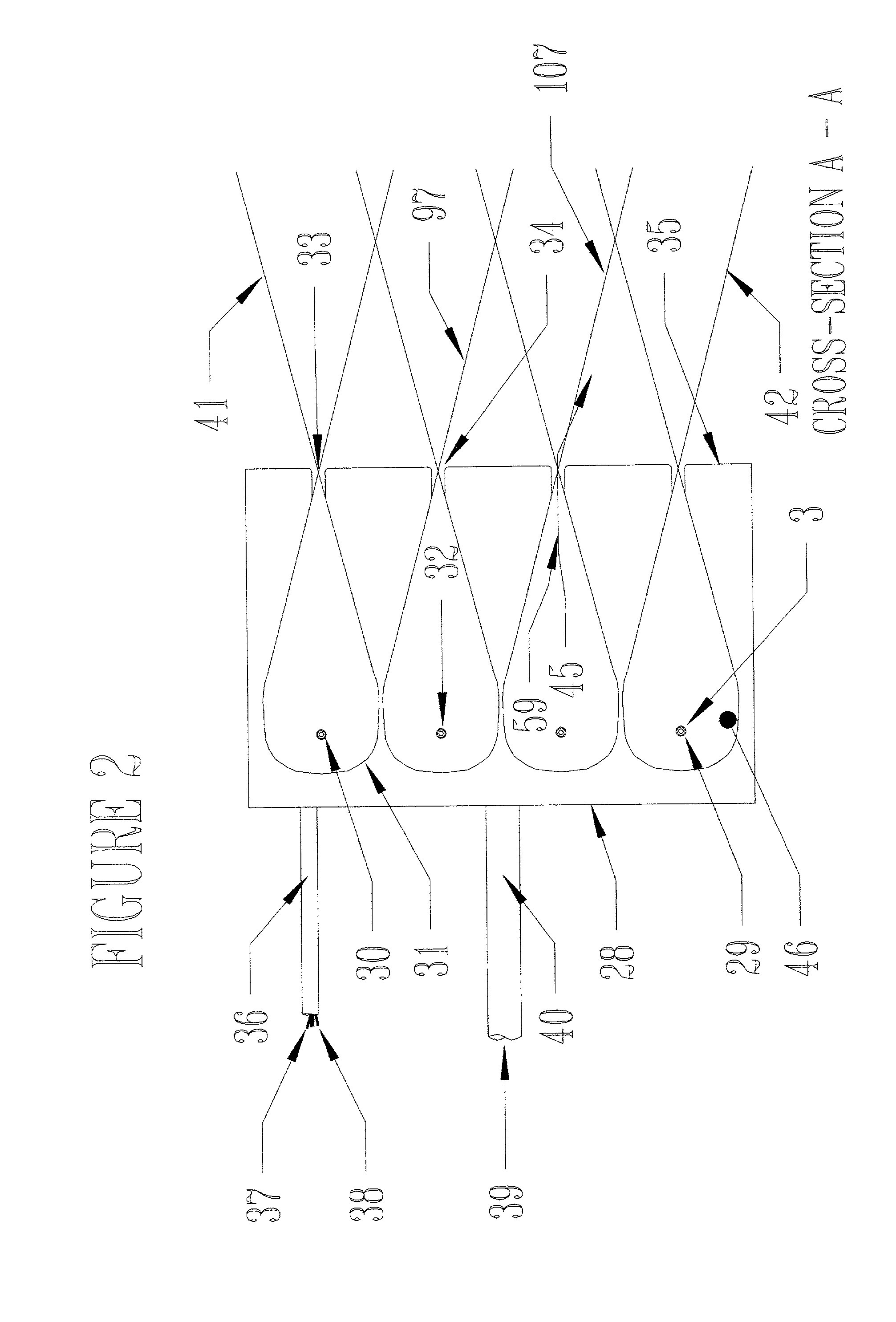

A misconception exists that all

infrared or

ultraviolet radiation loses power if sent over long distances.

However, the energy does tend to disperse at angles that dissipate its concentration, creating the illusion that the rays simply disappeared because of distance.

This means that some of the radiation will not be perfectly aligned in its delivery from a parabolic or elliptical reflector

system into the WGCL.

The WGCL will not efficiently absorb the radiation because its internal walls are highly reflective to the subject radiation.

Further, the small quantity of radiation that strikes the internal surfaces of the WGCL are at low angles of incidence that are not favorable for efficient absorption; generally less than a 10.degree.

angle of incidence.

This occurs over long periods of time, and has presented some major problems with the efficient maintenance of the processing equipment.

Safety issues have also occurred that are not recognized by safety laws.

However, it has been observed that

powder coating materials tend to migrate through the air over time, causing unwanted deposits in normally safe areas.

These deposits tend to accumulate to substantially thick proportions that hamper the maintenance of other radiant processing equipment.

This will cause a sudden contraction or shrinkage of the liquefied surface, while liquefied

powder coating of substantially higher temperature resides below the surface.

Login to View More

Login to View More