Processes for producing anatase titanium oxide and titanium oxide coating material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

The following examples and comparative examples further illustrate the present invention.

example a1

Titanium isopropoxide (14.96 g) was dissolved in 50 ml of isopropanol to prepare a titanium isopropoxide solution. A previously prepared mixture composed of 2.5 ml of 2 N hydrochloric acid, 3 ml of water, and 94.5 ml of isopropanol was added dropwise at a rate of 10 ml per min for 5 min, that is, in an amount of 50 ml, to the titanium isopropoxide solution. The molar ratio of titanium isopropoxide:water:hydrochloric acid in the titania sol solution thus obtained was 1:3:0.0.05.

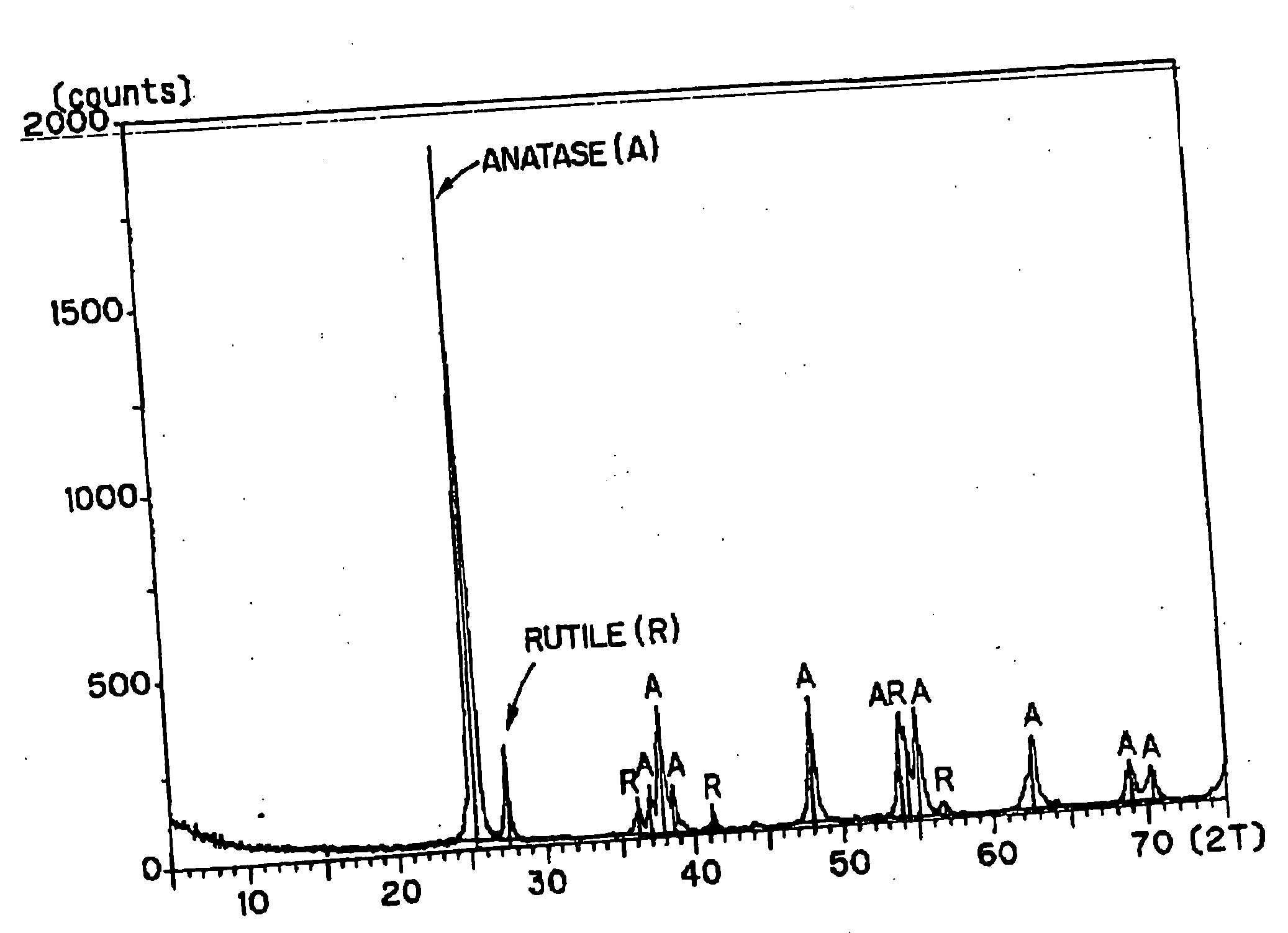

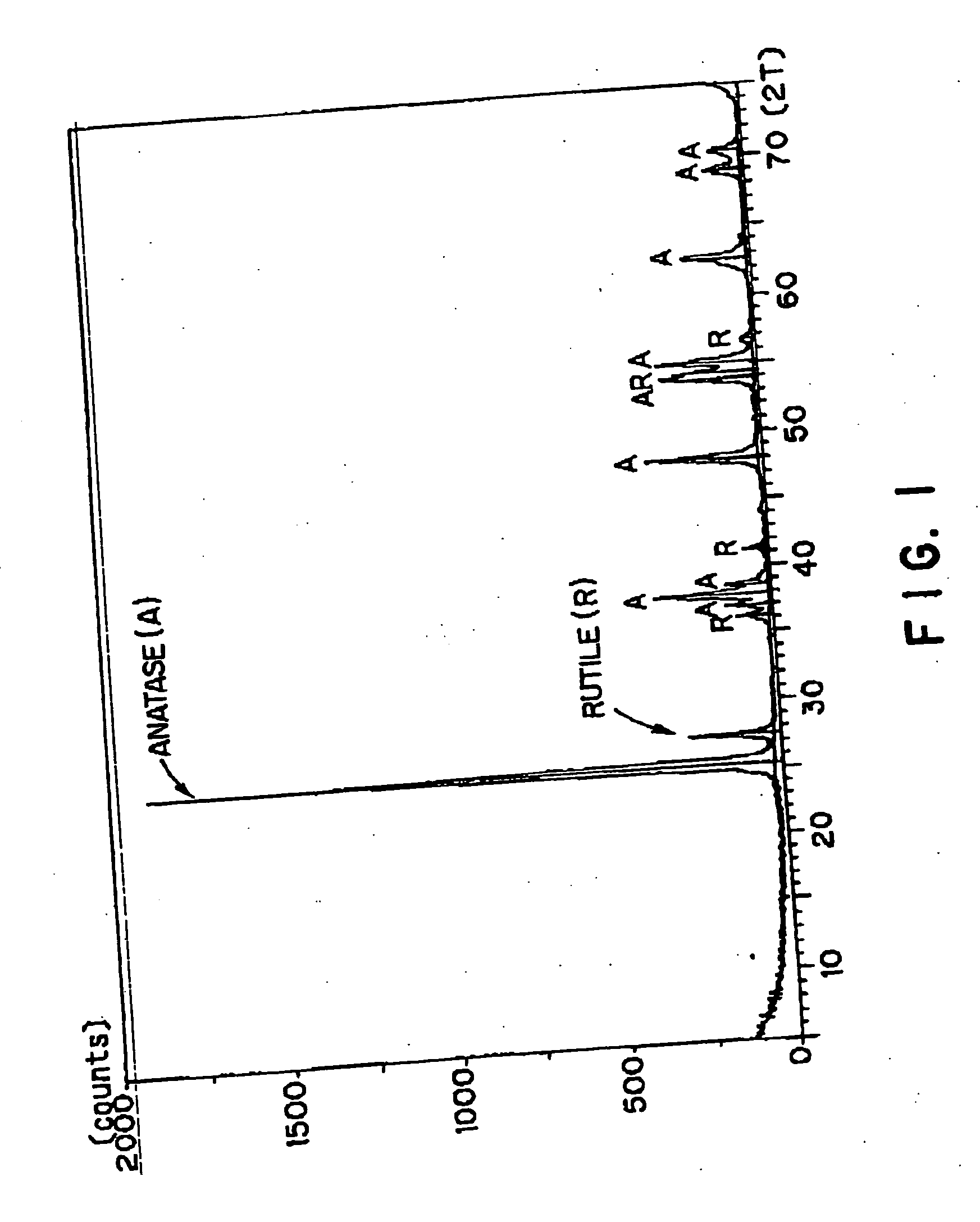

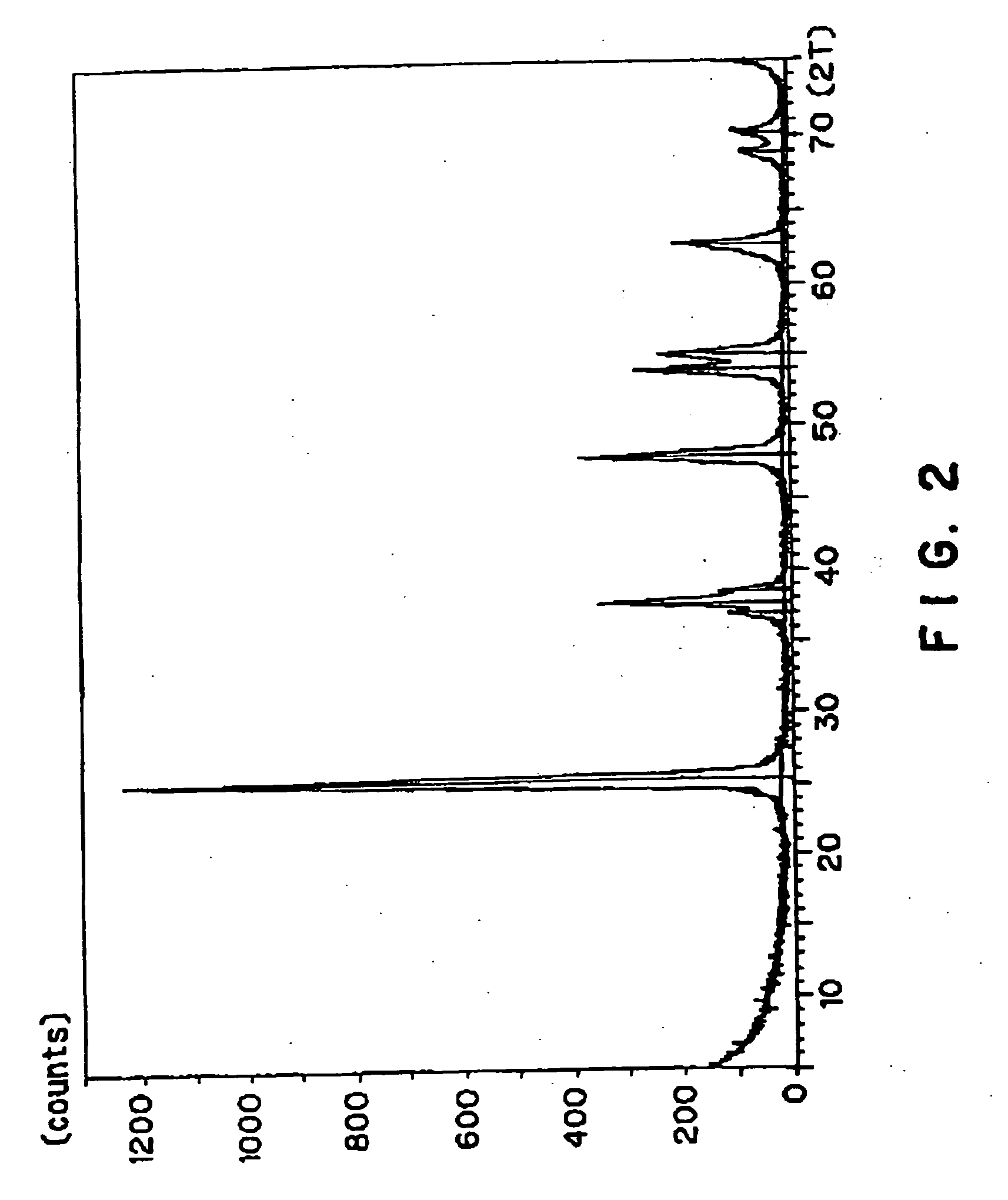

The transparent titania sol (50 g) was placed in a 100-ml vessel, and was held at 240° C. for 6 hr under hermetically sealed conditions. At that time, the pressure within the closed vessel was increased to 53 atmA. After the treatment, the resultant white powder was dried at 110° C., and the crystal structure thereof war then analyzed by X-ray diffractometry (XRD). As a result, as shown in FIG. 2, the crystal exhibited the same diffraction peak as P-25 (manufactured by Nippon Aerosil Co., Ltd.) of which the...

example a2

The transparent titania sol (50 g) prepared in Example A1 was placed in a 100-ml vessel, and was treated at 150° C. under hermetically sealed conditions for 6 hr. As a result, white powder was produced. As shown in FIG. 5, the analysis of this powder by X-ray diffractometry (XRD) revealed that anatase titanium oxide was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com