Fuel cell

a fuel cell and cell technology, applied in the field of fuel cells, can solve the problems of decreased durability, achieve the effects of reducing voltage, preventing contamination of cooling medium, and reducing corrosion curren

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

(1) First Embodiment

[0066] In producing a fuel cell of a First Embodiment according to the present invention, in particular, the types of stainless steel plate as a separator substrate are not restricted as long as the stainless steel plate is a corrosion resistant under an atmosphere in which a fuel cell is used. Concretely, various ferrite-types, austenite-types, or a two phase-types of stainless steel can be used. The stainless steel plate desirably contains Cr of not less than 12 mass %. The thickness of the stainless plate is desirably 0.05 to 0.3 mm in consideration of assembly of the fuel cell.

[0067] A passivation film naturally generated in air is formed on a stainless steel separator surface under an environment in which the fuel cell is used. In the condition in which the above passivation film is naturally generated, an oxidation electrode side separator surface is sufficiently oxidation resistant even when exposed to an oxidation atmosphere. It is therefore not necessar...

examples 1 to 3

(A) EXAMPLES 1 TO 3 AND COMPARATIVE EXAMPLES 1 AND 2

[0070] The present invention will be described in detail hereinafter by way of Examples and Comparative Examples.

[0071] A passivation treatment performed on a stainless steel separator surface will be explained. In order to prevent release of metal ion impurities from a separator surface, the separator surface was subjected to a nitric acid, so that a passivation film was formed which was Cr-enriched. In Examples 1 to 3, a stainless steel having a composition shown in Table 2 was immersed in a nitric acid solution of 50 mass %. The immersing time was 5, 30, or 120 minutes. In Comparative Examples 1 and 2, a stainless plate which was not subjected to a passivation treatment and a stainless plate which was boiled in nitric acid solution of 50 mass % for 24 hours were used as a sample. Next, compositions of the above passivation films were analyzed by Auger Electron Spectroscopy. Table 3 shows measurement results of maximum ratio of ...

second embodiment

(2) Second Embodiment

[0085] A second preferred embodiment of the present invention will be described hereinafter with reference to the Figures.

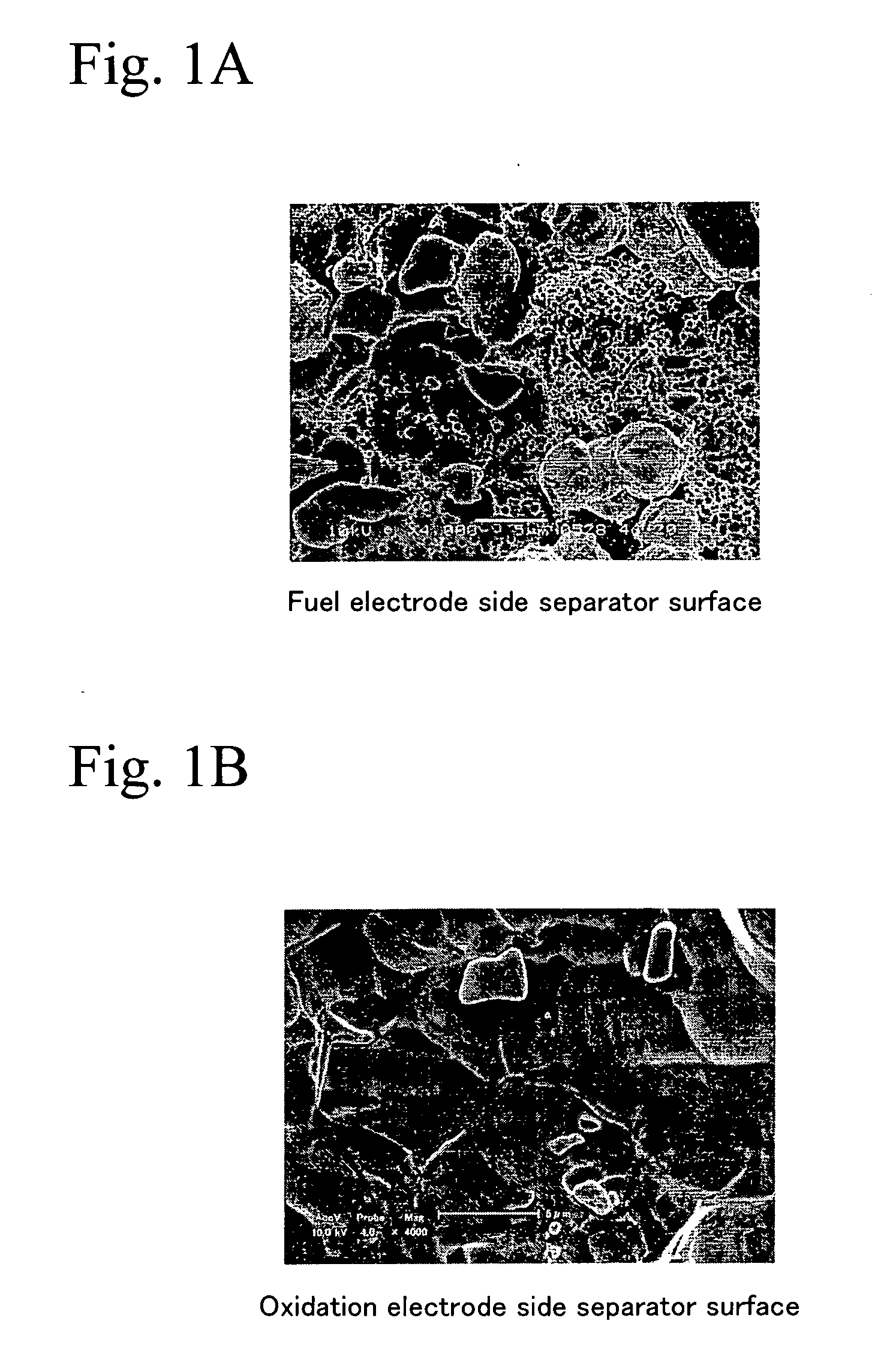

[0086]FIG. 2 is a cross sectional view showing a cell structure in a fuel cell of the Second Embodiment according to the present invention. As shown in FIG. 2, a cell has a MEA 201, an anode separator 202, a cathode separator 203, and a cooling medium 204. The anode separator 202 and the cathode separator 203 are opposite to both sides of the MEA 201. The cooling medium 204 is disposed between the anode separator 202 and the cathode separator 203 at a position in which a MEA is not disposed therebetween. A fuel cell of the Second Embodiment according to the present invention has a stacked structure such that the above plural cells are stacked.

[0087] In the above cell, cooling medium 204 is circulated between a surface opposite to a side of the anode separator 202 contacting the MEA 201 and a surface opposite to a side of the cathode separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com