Flame retarded fibers and filaments and process of production therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

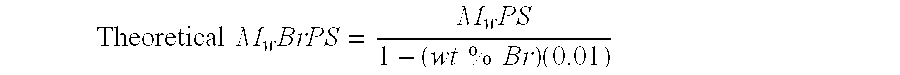

Method used

Image

Examples

example 1

[0102] In a melt spinning apparatus, dried polyethylene terephthalate is mixed with the desired amount of polybrominated anionic styrenic polymer at 280′-300° C., and the melt is extruded into a water bath as strands. The fibers obtained are woven to form a fabric. To evaluate flame retardancy, the fabric is subjected to the small-scale NFPA-701 test (1989), a standard test established by the National Fire Protection Association. In the NFPA-701 test, a 2 inch by 10 inch piece of cloth is stretched taut over a frame, and hung vertically. This piece of fabric is put three-fourths of an inch into a 1.5 inch flame for 12 seconds. The char length, drip burn, and weight loss of the fabric are measured. To pass the NFPA-701 test, a material should have a drip burn time of zero seconds.

example 2

[0103] In a melt spinning apparatus, the desired amount of polybrominated anionic styrenic polymer is added to a molten nylon (polyamide), and the melt is extruded to give fibers or filaments. The fibers or filaments are knitted to form a fabric. Flame retardancy is evaluated by subjecting the fabric to the NFPA-701 test as described in Example 1.

example 3

[0104] In a melt spinning apparatus, the desired amount of polybrominated anionic styrenic polymer is added to a molten polypropylene, and the melt is extruded to give fibers or filaments. The fibers or filaments are woven to form a fabric. To evaluate flame retardancy, the fabric is subjected to the NFPA-701 test as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com