Polymeric foam powder processing techniques, foam powders products, and foams produced containing those foam powders

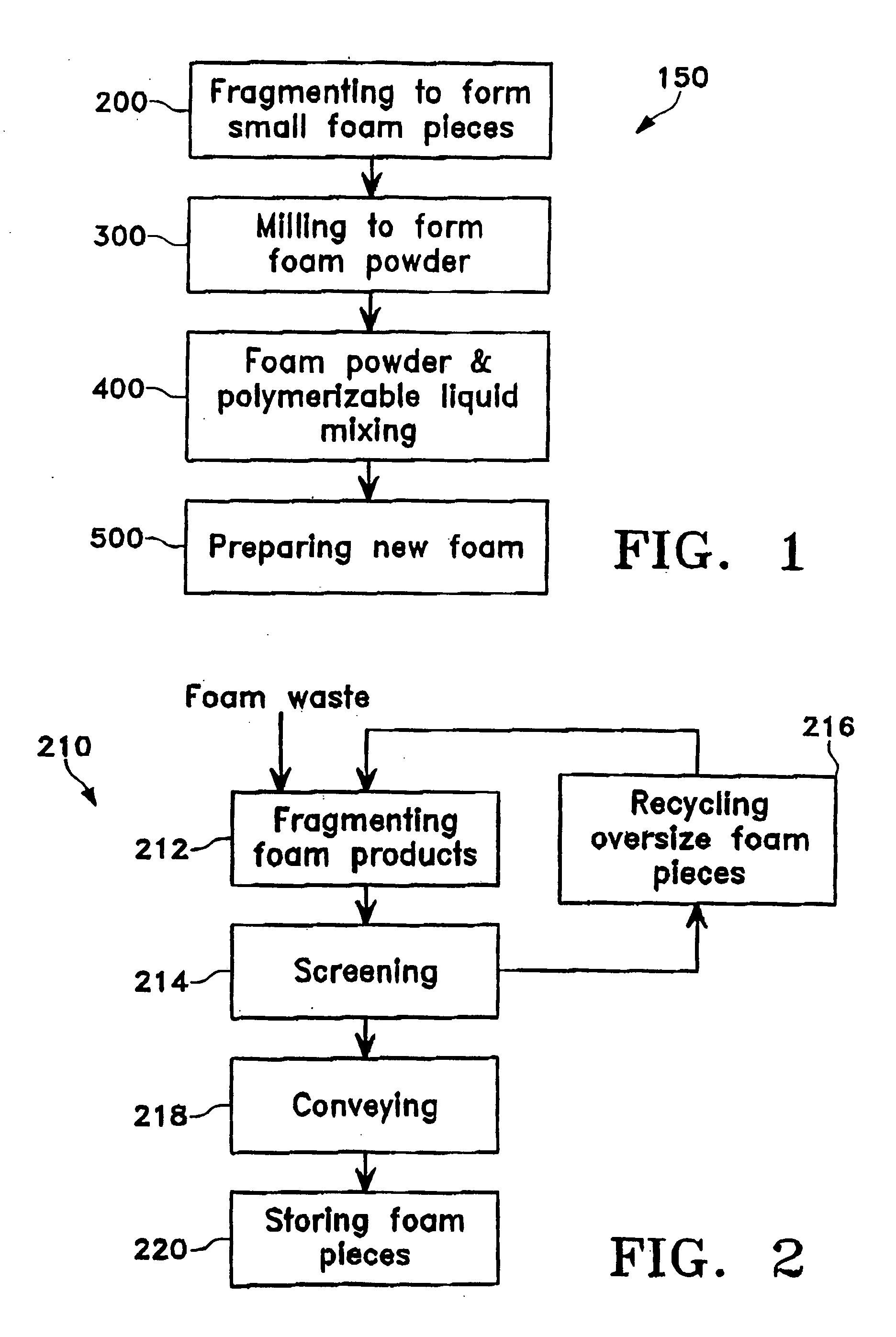

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0116] Flexible-slabstock polyurethane foam production scrap was obtained from trimming the skins from foam buns. The scrap contained dense skin material and polyethylene film, with the balance being polyurethane foam of varying density. This scrap material was first reduced to pieces with a size of approximately 1 cm. The foam pieces were then comminuted on 56-cm-diameter, 152-cm-length counter-rotating rolls such as those shown in FIG. 11 with speeds of 27 and 80 rpm. The resulting material was scraped together and quenched as it exited the rolls, and exposed to a turbulent air flow at room temperature. The material was discharged together with the air flow and conveyed to a sifter. The material was screened in the sifter, resulting in a fine foam powder having the particle-size distribution shown in Table 1. A coarse fraction that was also obtained from the sifter was returned to the counter-rotating rolls. The fine foam powder collected from the sifter was subsequently used to m...

example 2

[0117] Flexible-slabstock polyurethane foam production scrap was obtained from trimming the skins from buns of foam made with polyether polyols. The scrap material included 2.3% by weight of high-density polyethylene film with a thickness of about 25 microns, and 30% by weight of dense skin material, with the balance being polyurethane foam of varying density. This scrap material was first reduced to pieces with a size of approximately 3 cm by means of a rotary grinder. The foam pieces were then comminuted on 30-cm-diameter, 45-cm-length counter-rotating rolls such as those shown in FIG. 11 with speeds of 30 and 120 rpm. The resulting material was scraped together and quenched as it exited the rolls, and exposed to a turbulent air flow at room temperature. The material was discharged together with the air flow and conveyed to the inventive sifter as shown in FIG. 13A. The material was screened in the sifter, resulting in a fine foam powder having the particle-size distribution shown...

example 3

[0118] A slurry sample was prepared by mixing 15 parts of the fine polyurethane powder described in Example 1 with 100 parts of VORANOL® 3137 polyether polyol from The Dow Chemical Company. This polyol is a liquid polyhydroxyl compound having a viscosity of about 460 centipoise at a temperature of 25° C.

[0119] The beneficial size reduction effects which are obtained by high-shear mixing of polyurethane powder in a polyhydroxyl compound are illustrated in FIGS. 22 and 23. After taking a small sample to measure particle size before high shear mixing, the remaining batch was subjected to 2.5 minutes of high shear mixing using a Silverson L4R laboratory high shear mixer. The mixer generates fluid shear by means of centrifugal action of a rotor in a high shear rotor / stator workhead. Particle size analysis was performed using a laser-diffraction technique with a Mastersizer 2000 from Malvern Instruments, Southborough, Md.

[0120] The results are shown in the graphs depicted in FIGS. 22 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com