Scribing sapphire substrates with a solid state UV laser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

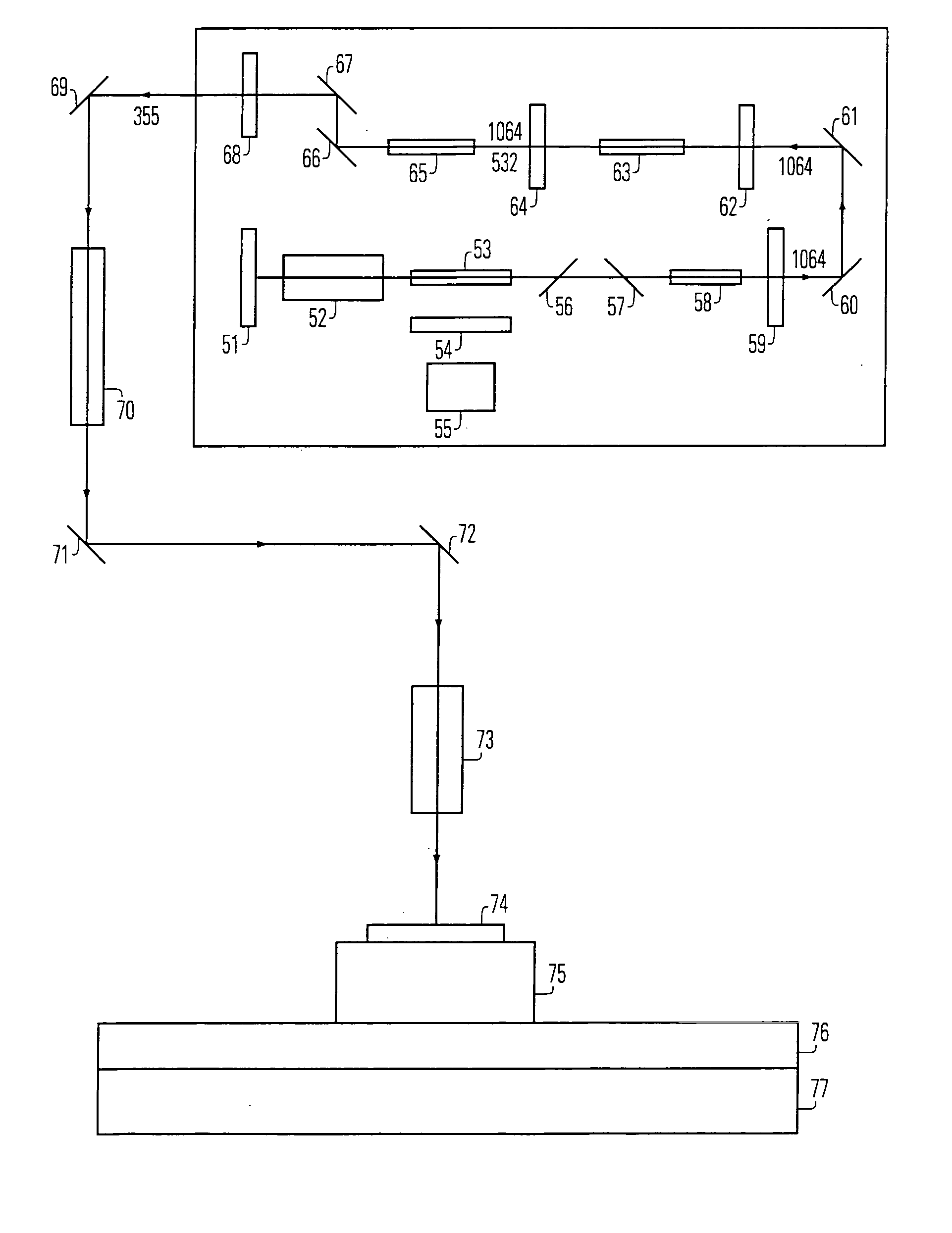

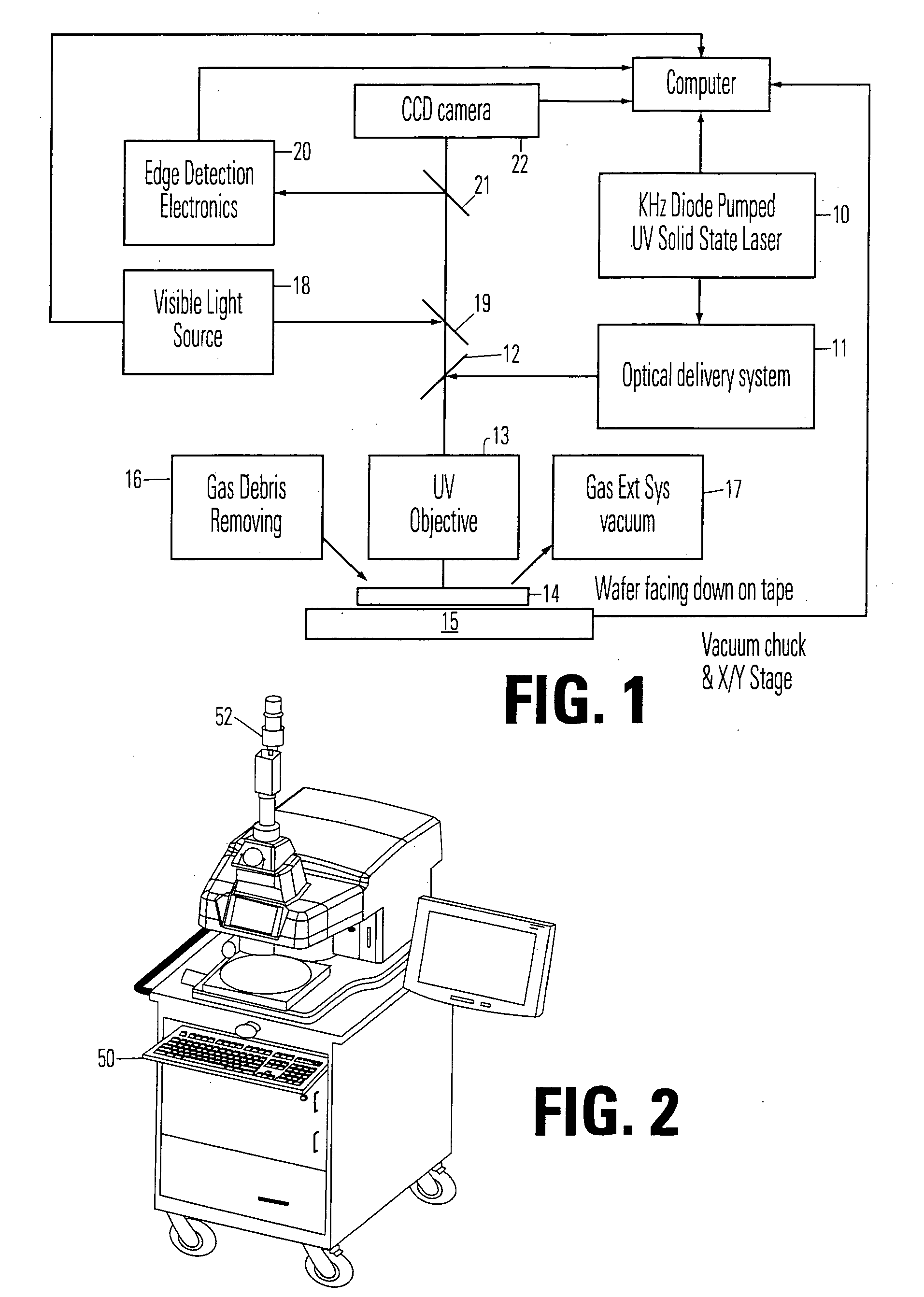

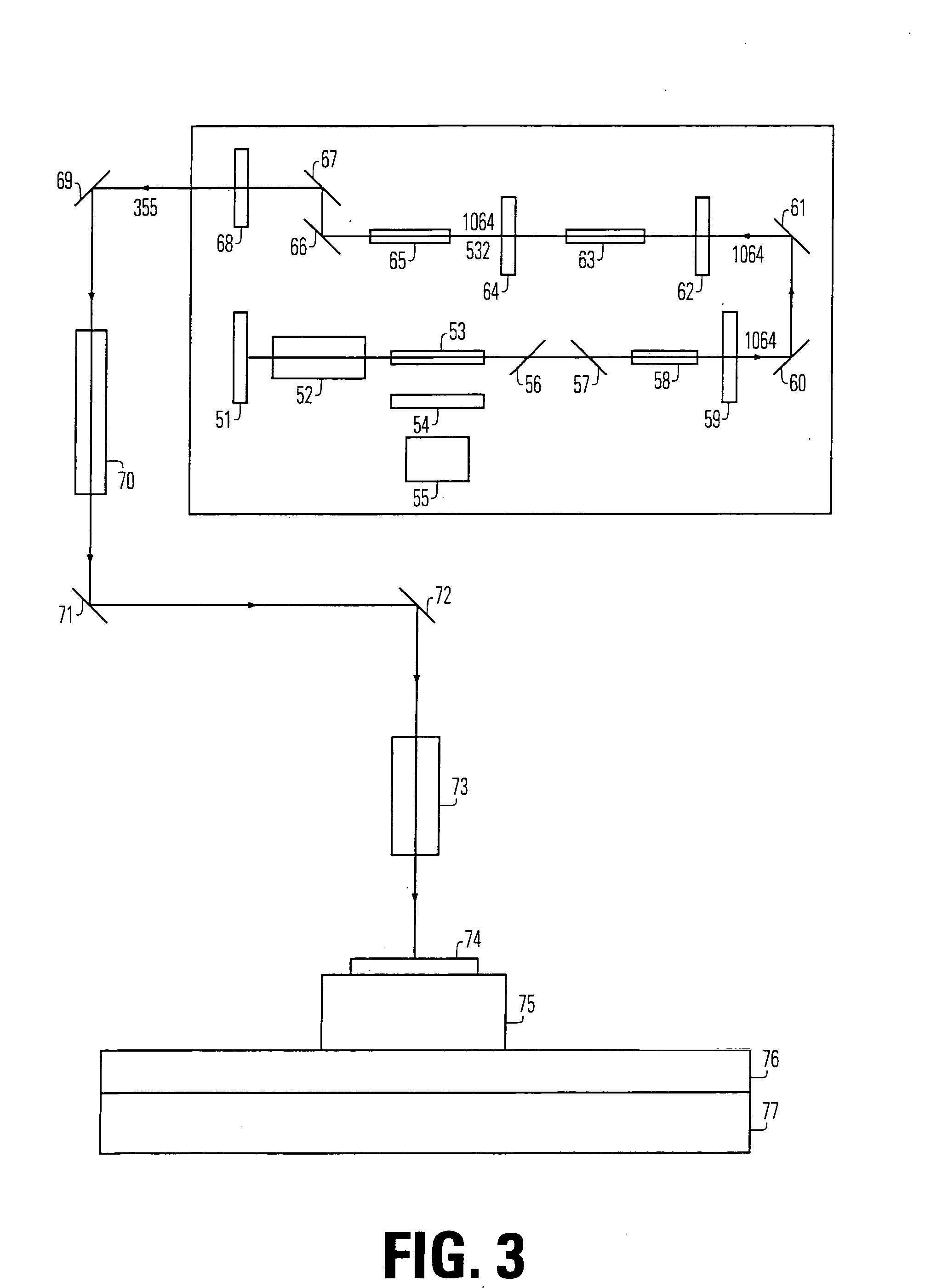

[0030] A detailed description of embodiments of the present invention is provided with reference to FIGS. 1 through 8A-8C, and experimental results are shown in FIGS. 9-16.

[0031]FIG. 1 is a simplified block diagram of a sapphire scribing system according to the present invention. In the embodiment shown, a diode pumped, solid-state laser 10 generates high-density UV and close-to-UV pulses at a repetition rate in the kHz range. In preferred systems, the laser comprises a Q-switched Nd:YVO4 medium delivering third harmonic output as the stream of laser pulses at a repetition rate greater than 10 kHz, with a pulse duration of about 40 nanoseconds. The pulses are provided using an optical delivery system 11 and turning mirror 12 to an ultraviolet objective lens 13, which focuses the pulses on a sapphire substrate 14. The substrate 14 is supported on a vacuum chuck and X / Y stage 15. Preferably, the wafer is supported face down on an adhesive wafer tape. A gas debris removing system 16 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com